Wireless cutter damage detection device for processing center and detection method thereof

A machining center and damage detection technology, which is applied in the direction of manufacturing tools, metal processing equipment, and electromagnetic wave detection, can solve the problems of high price, interference of fixture installation, etc., and achieve the effect of cheap price, simple structure, and no processing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

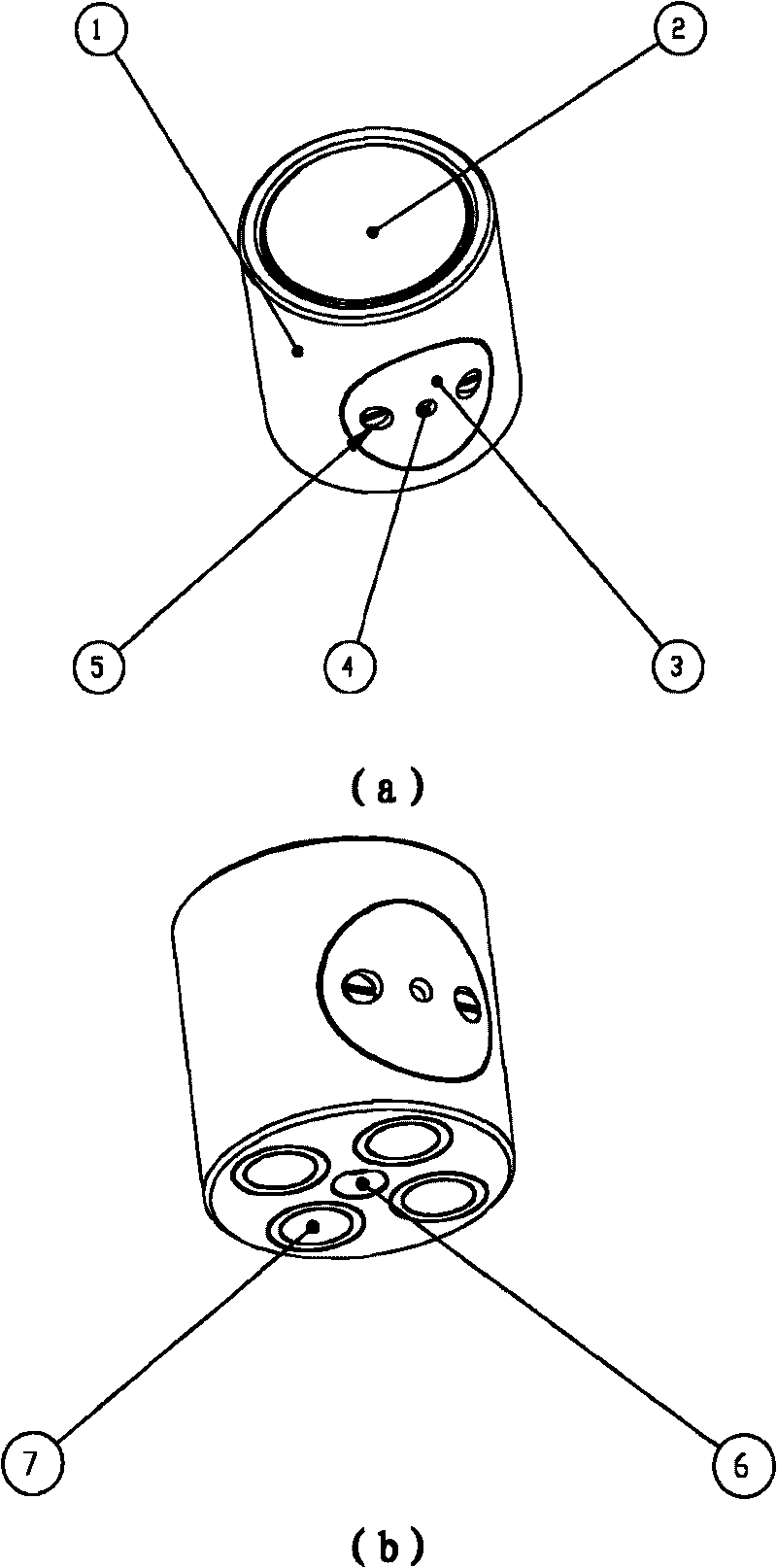

[0030] Embodiment: The machine tool controller adopts PLC, and four powerful magnets 7 are arranged in the mounting holes on the bottom surface of the base 1 .

[0031] During work, this device is fixed in the suitable position that does not affect fixture work in the machine tool by 4 powerful magnets 7 at the bottom. When a tool is processed, it is controlled by the CNC program to move quickly to about 5mm above the device, and then move at a low speed at the feed rate until it touches the retractable mandrel. Since the spring is installed under the retractable mandrel, it can have a range of movement of about 5mm, which is to avoid damage to the tip of the tool. The final stop position of the tool is strictly controlled by the machining program. This position must ensure that the tip of the tool touches the retractable mandrel and avoid damage to the tip of the tool. Generally, it can be 0.1mm down after contact. At this moment, the retractable mandrel 2 touches the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com