Wind speed-reducing water mist removing device

A water mist and wind speed technology, applied in the field of industrial waste gas treatment devices, can solve the problem of unsatisfactory removal of water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

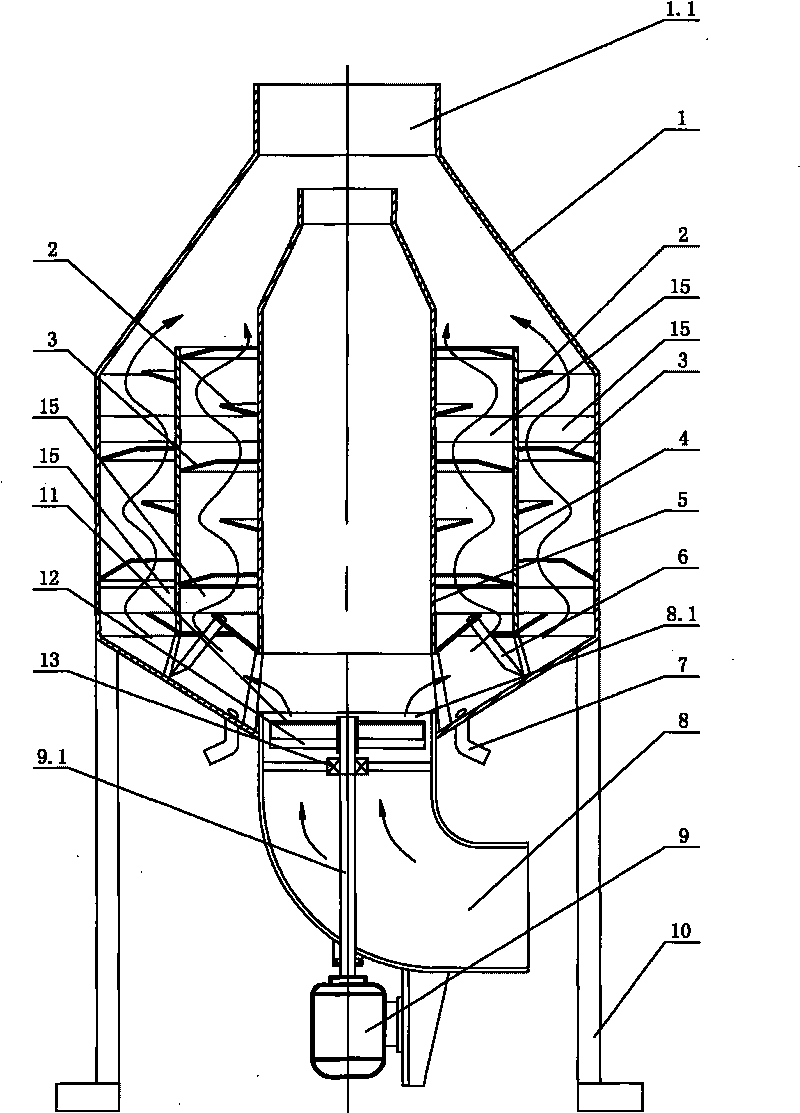

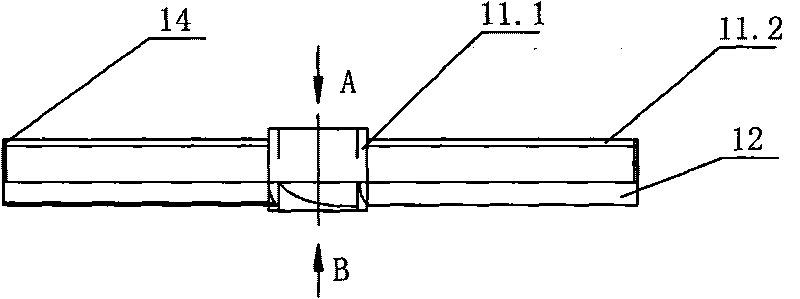

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a device for reducing wind speed and demisting, which includes an elbow joint 8 connected to the air inlet pipe and a purification cartridge connected to the air outlet 8.1 of the elbow joint. A motor 9 is fixedly installed at the bottom of the elbow joint 8, the output shaft 9.1 of the motor 9 extends into the elbow joint 8 and points to the air outlet 8.1 of the elbow joint, and the fan blade 12 is installed on the output shaft 9.1 of the motor 9, and the fan blade 12 rotates The airflow and water mist in the intake pipe can be quickly drawn and transported into the purification cartridge. A centrifugal shunt 11 is also installed on the motor output shaft 9.1, and the centrifugal shunt 11 is located above the fan blade 12. The centrifugal shunt 11 includes a shaft sleeve 11.1 fixed to the motor output shaft 9.1 and uniformly distributed on the A plurality of elongated baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com