Rock-fill material weathering instrument

A technology of rockfilling and weathering, applied in the field of weathering instruments, can solve the problems of inability to realize the function of the dry-wet cycle coupling effect, and achieve the effects of avoiding errors, reducing friction, and quickly controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

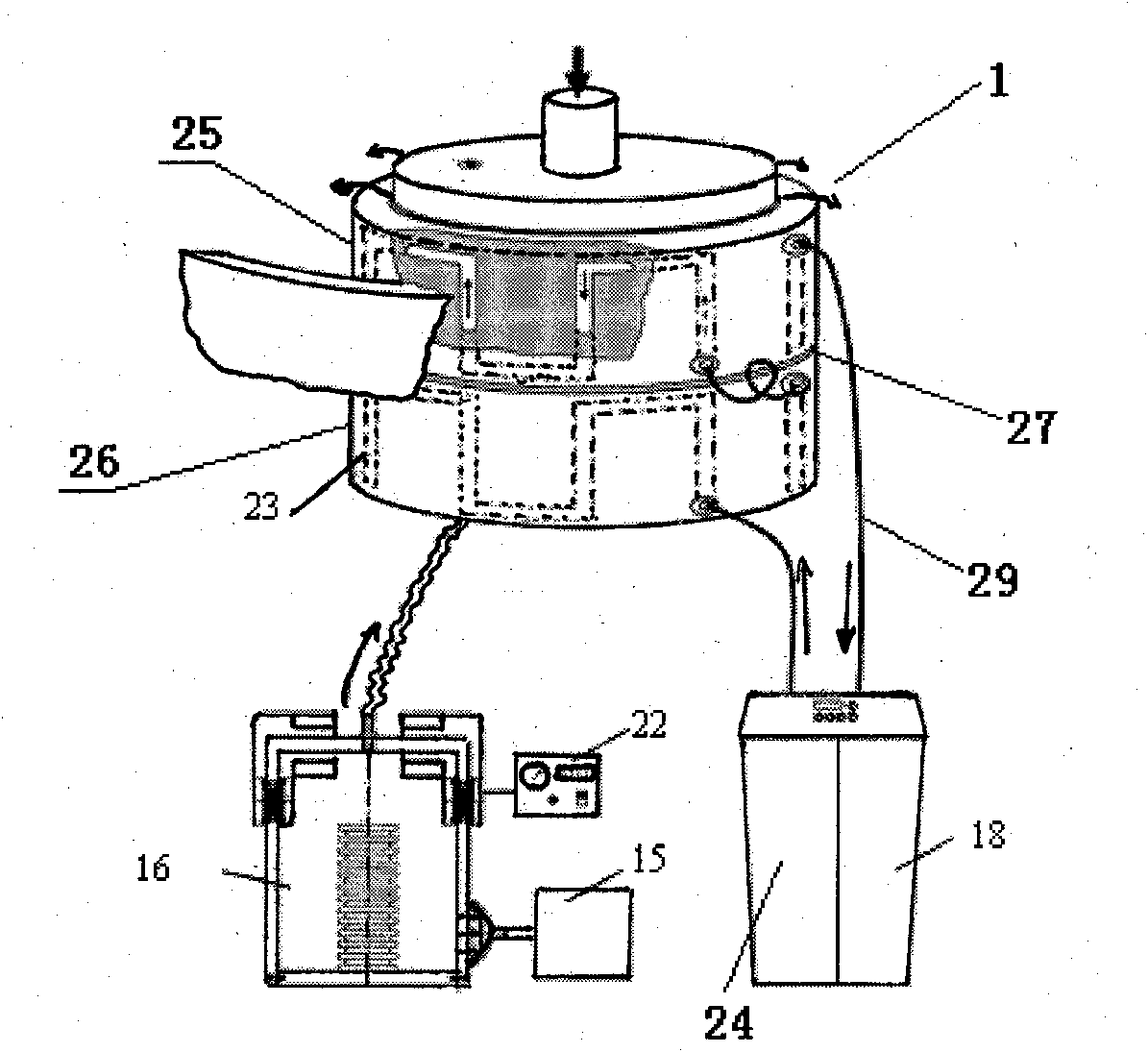

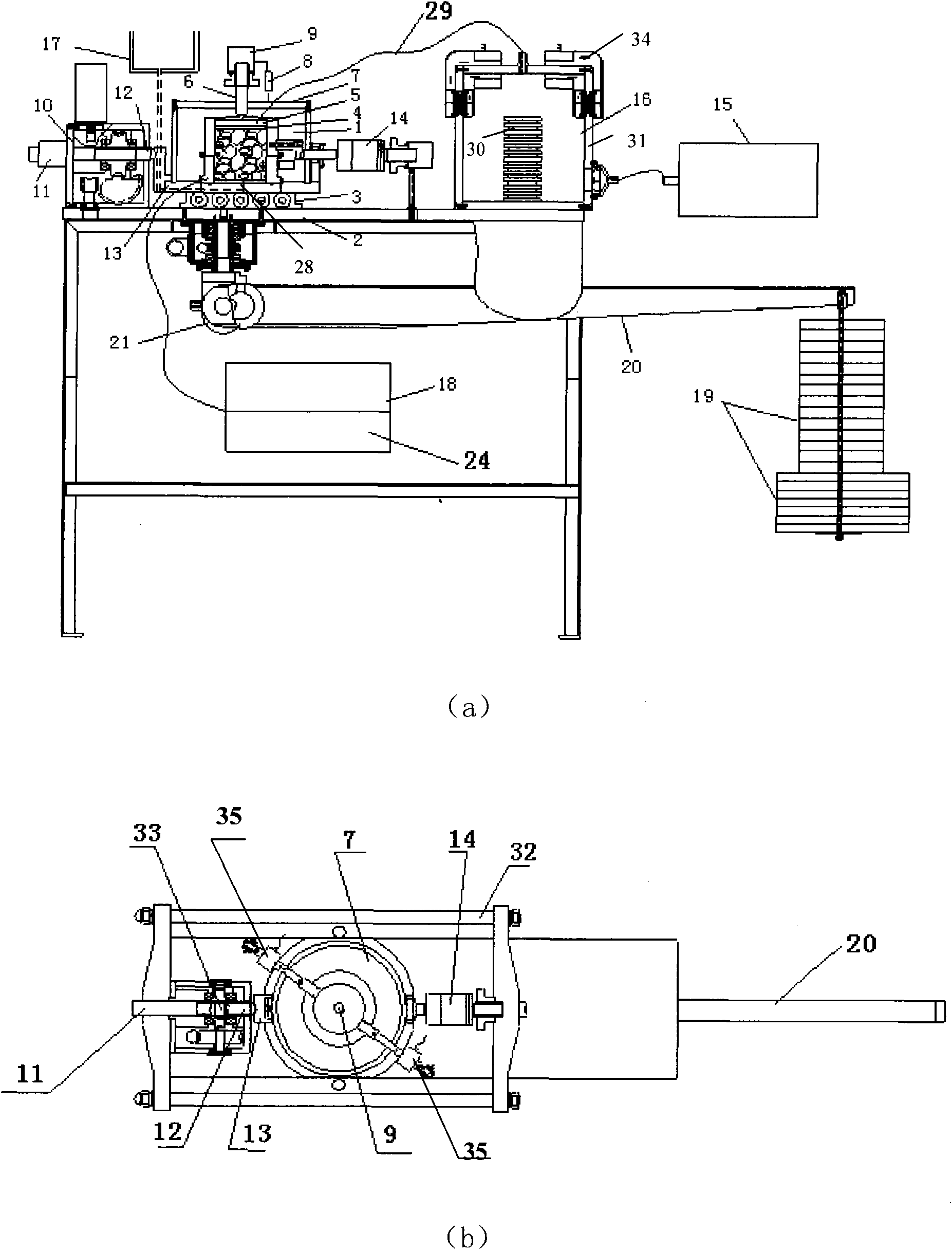

[0022] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

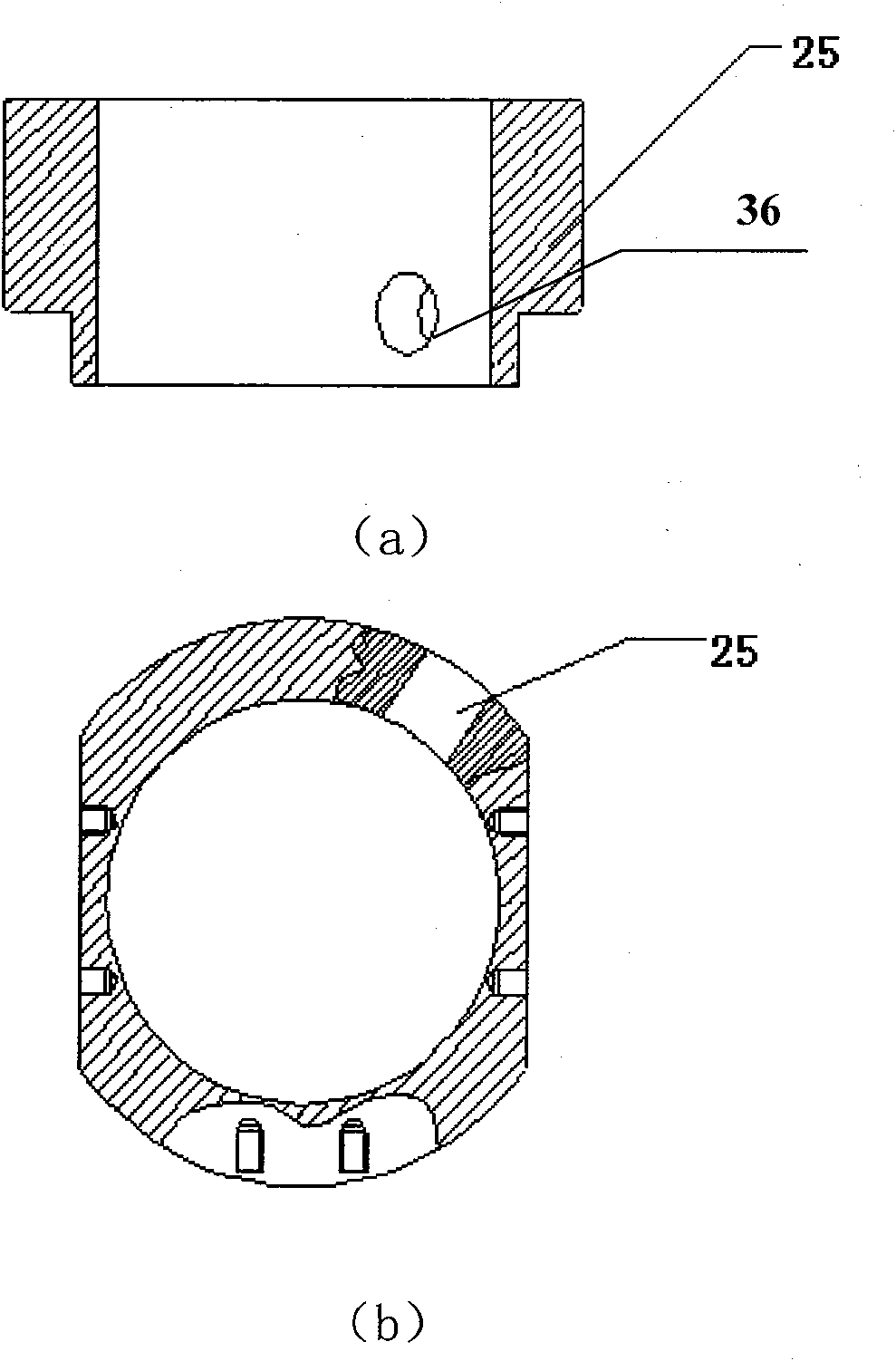

[0023] see figure 1 , a rockfill material weathering instrument, including a bracket base 2, a rolling bearing 3 is arranged on the upper part of the bracket base 2, a compression shear test box 1 is arranged on the rolling bearing 3, and the function of the rolling bearing is to reduce the gap between the compression shear test box 1 and the compression shear test box 1. friction, the U-shaped circulating sleeve 23 set in the compression shear test box 1, which provides a channel for circulating heat or cooling in the side wall of the sample for the high and low temperature liquid, and the upper part of the shear test box 1 is set in turn. There are permeable board 4, pressurizing cap 5, pressurizing head 6 and heat preservation cover 7, the inner side of heat preservation cover 7 is lined with heat preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com