Permanent connection structure of lighting tubes in light fitting

A technology for lamp tubes and lamps, which is applied to the components of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., and can solve problems that affect lighting operations, and the fixing structure of the fixed end of the lamp tube is not stable enough, easy to loosen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

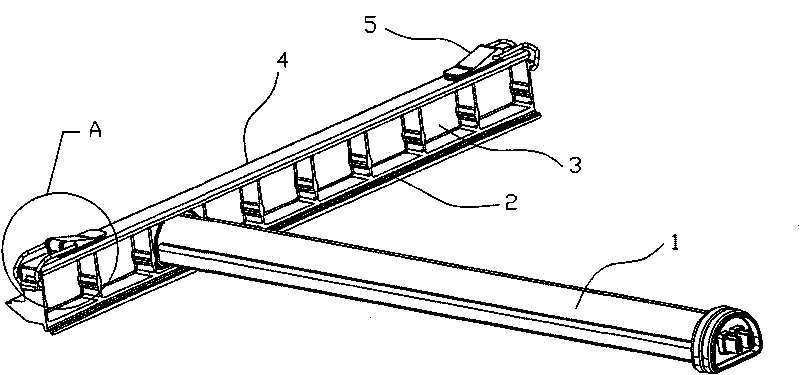

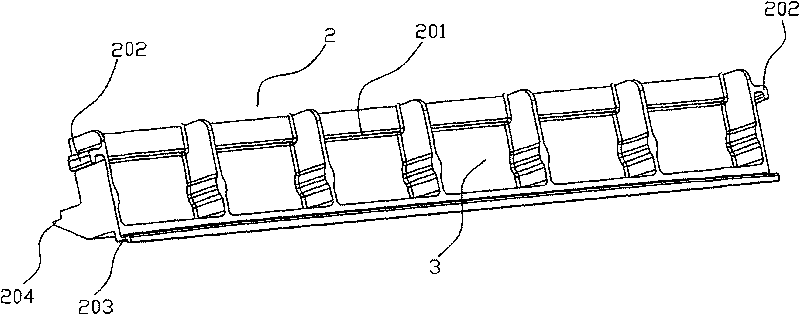

[0017] like Figure 8 and Figure 9 As shown, the LED street lamp in this embodiment includes a plurality of lamp tubes 1 arranged side by side, a lamp holder 7, a fixing seat 2, a lamp holder 8 and an upper casing 9, and the upper casing 9 is fixedly arranged above the lamp holder 8, and the lamp The front end of the frame 8 is equipped with a pipe 11 and a power supply 10 for street lamps. The lamp holder 7 is fixed on the frame of the lamp holder 8 and is electrically connected with the power supply 10. A row of lamps is provided on the lamp holder 7. The plug end of the lamp tube 1 is inserted into the lamp holder 7, the fixed end of the lamp tube 1 is fixed in the fixing seat 2, and the lamp tube 1 is fixed.

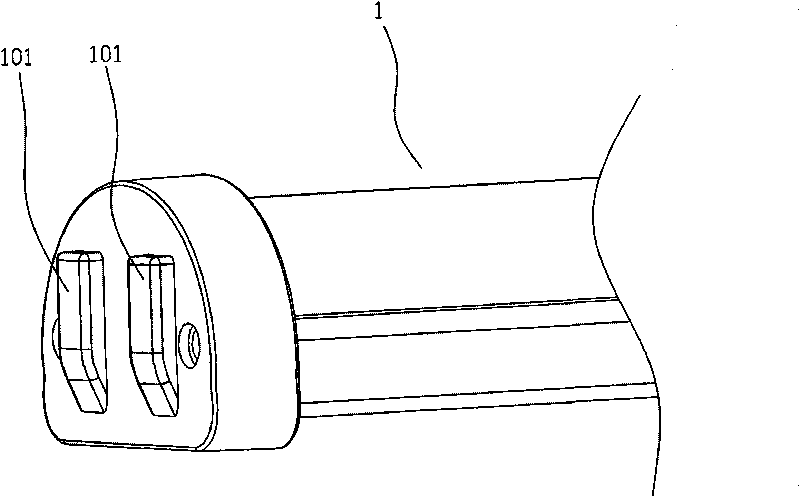

[0018] The specific fixed connection structure of the lamp tube is as follows: Figure 1 to Figure 7 As shown, the fixed base 2 is provided with a number of slots 3 with upper openings, so that the lamp tube 1 can be put down smoothly, and the plug end of the lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com