Method for constructing liquified discarded soil in construction of subaqueous structure

A construction method and structure technology, applied in construction, hydraulic engineering, infrastructure engineering, etc., can solve the problems of expansion, destruction of surrounding buildings, high construction costs, etc., and achieve the effects of reducing costs, avoiding landslides, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

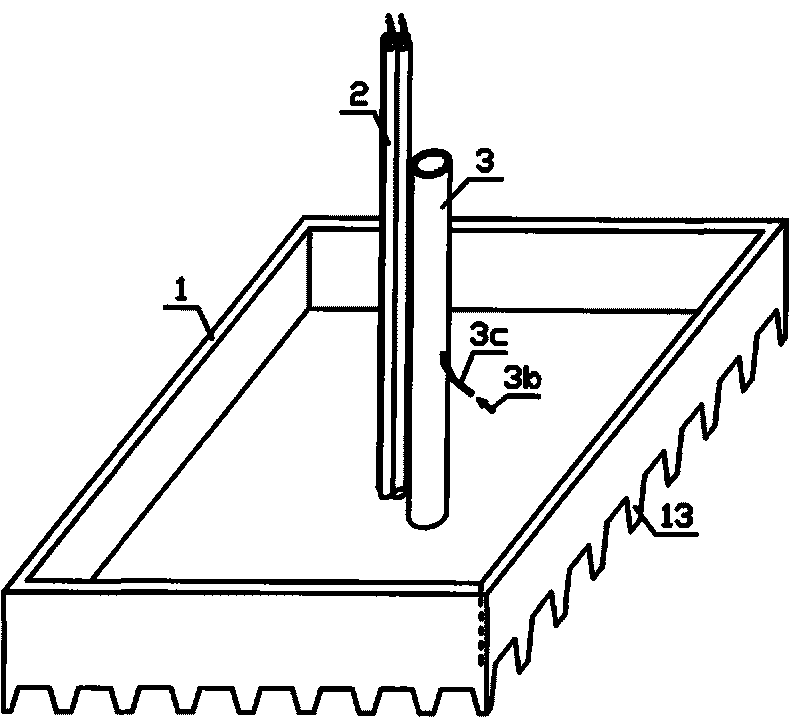

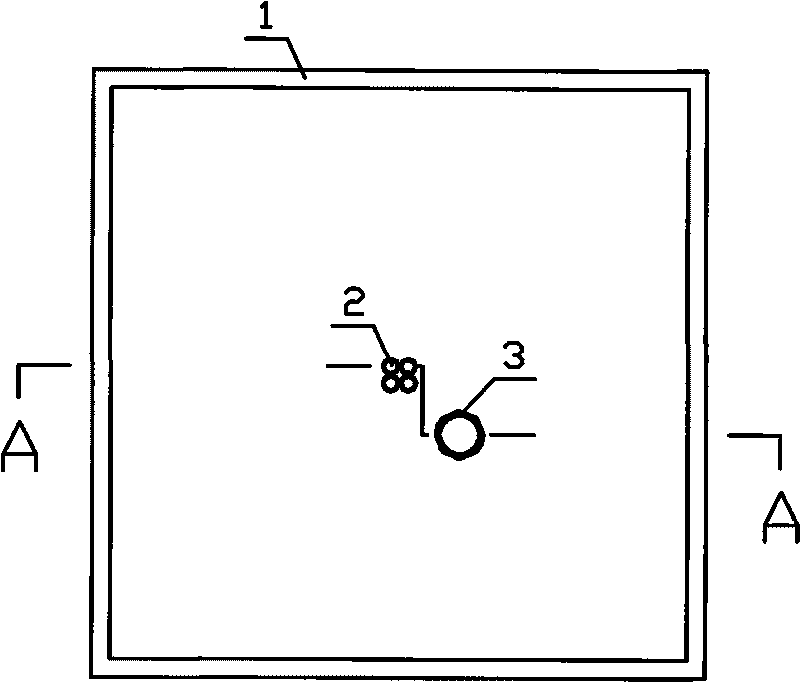

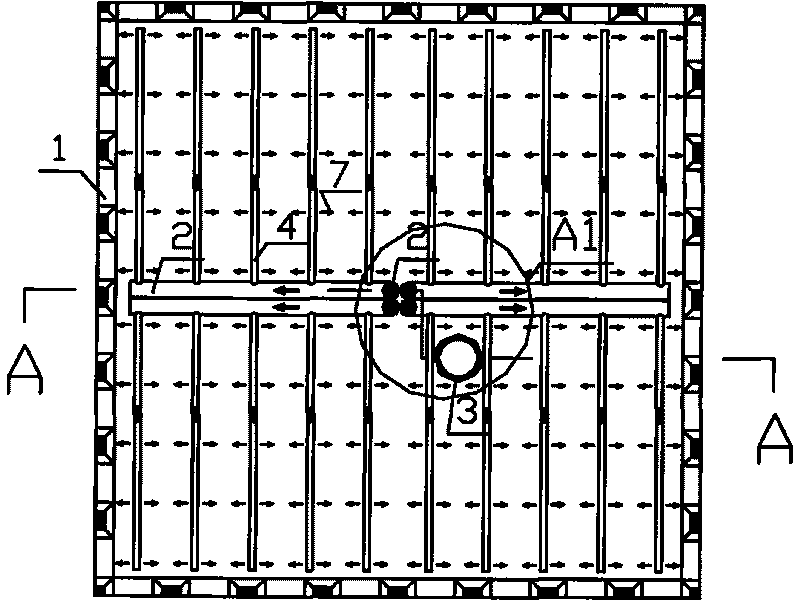

[0065] see Figures 1 to 5 , this embodiment is: the high-pressure water or gas conveying branch pipe 4 is installed under the bottom of the box, and the injection holes are directly opened on the branch pipe 4; the method of liquefying the soil is to inject high-pressure water or gas.

[0066] 1. If Figures 1 to 2 , in the prefabrication field, make a box body 1 with a bottom plate and an upper opening, and there are blade feet 13 around the bottom of the box (the shape of the blade feet can be other shapes); install 4 high-pressure water or gas main pipes 2 in the box. There can be multiple high-pressure water or gas delivery pipes, depending on the specific situation, and the same for other embodiments. The 4 main pipes 2 penetrate the bottom of the tank and are respectively connected with 4 groups of high-pressure water or gas conveying branch pipes 4 under the bottom of the tank; a mud discharge pipe 3 that penetrates the bottom of the tank is also installed in the tank...

Embodiment 2

[0070] see Figures 6 to 11 , this embodiment is: the high-pressure water or gas conveying branch pipe 4 is installed in the bottom plate of the box, and the high-pressure water or gas is injected through the nozzle 6; the method of liquefying the soil is to inject high-pressure water or gas.

[0071] 1. If Figures 6 to 8 , in the prefabrication field, make a box body 1 with an upper opening with a bottom plate, and there are blade feet 13 around the bottom of the box (the shape of the blade feet can be other shapes); install 4 high-pressure water or gas main pipes 2 in the box, the 4 The main pipe 2 is respectively connected with 4 groups of high-pressure water or air conveying branch pipes 4 in the box, and there are multiple outlets on each branch pipe 4 which are respectively connected with independent water or air gun rods 5; the cross-sectional area of each conveying main pipe 2 is larger than 1.2 times the sum of the cross-sectional areas of the branch pipes 4 conne...

Embodiment 3

[0075] see Figures 12 to 16 , This embodiment is similar to Embodiment 2, the difference is that the nozzle 6 is changed to a pressure vibrator 8; the method for liquefying the soil is that the pressure vibrator 8 generates high-frequency vibration.

[0076] 1. If Figures 12 to 16 , the production of the box 1 and the production of the high-pressure liquid or gas conveying main pipe 2, the conveying branch pipe 4 and the mud discharge pipe 3 are the same as those of the embodiment 2, and the size of the cross-sectional area of each pipe is also the same as that of the embodiment 2.

[0077] Several pressure vibrators 8 are installed at the end of each gun rod 5, and its power source is provided by a pressure machine (such as pulse hydraulic pump, pulse air pump) that can generate periodic positive and negative pressure, and the transmission method is through 4 high-pressure The liquid or gas conveying main pipe 2 reaches the pressure vibrator 8 through the conveying branc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com