Construction method of composite steel sheet pile cofferdam for deep-water cap of steep-slope hard-rock river bed

A technology of steel sheet pile cofferdam and steel sheet pile, which is applied in basic structure engineering, construction and other directions, can solve the problems of strengthening the back cover concrete, affecting the construction progress, and large environmental disturbance, so as to ensure structural safety, reduce construction difficulty, and ensure construction safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Using the above design to construct the composite steel sheet pile cofferdam for the deep-water cap of the steep-slope hard-rock river bed, the specific steps are as follows:

[0026] Step 1: Stakeout and positioning, mark the axis position of the steel sheet pile cofferdam, set up the construction platform on the water, and enter the relevant piling equipment;

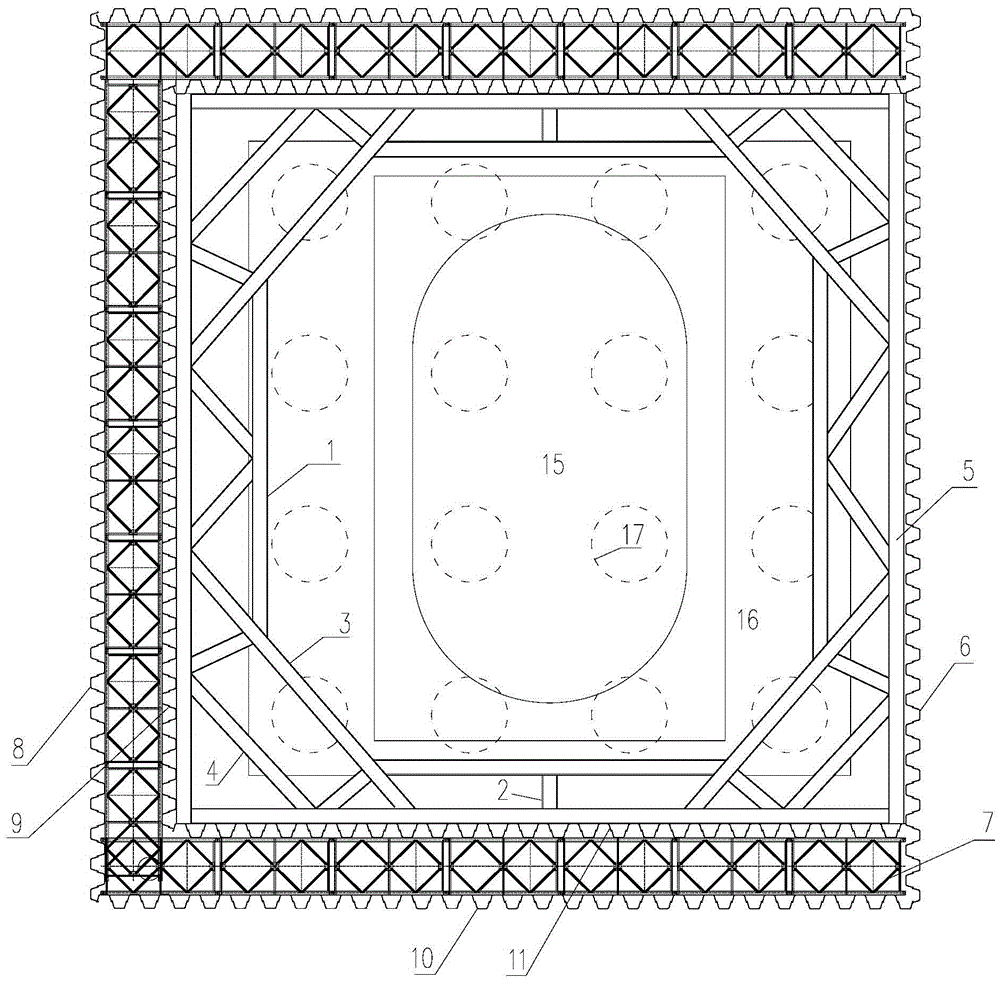

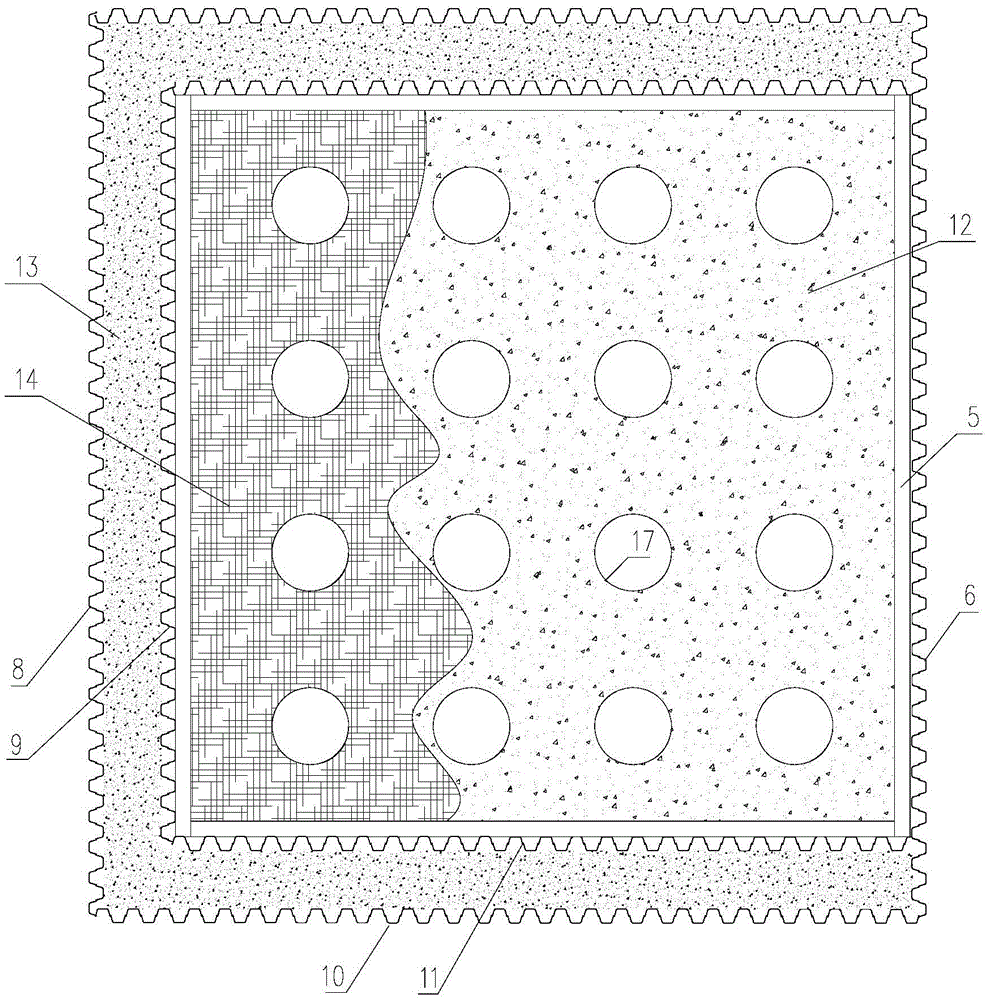

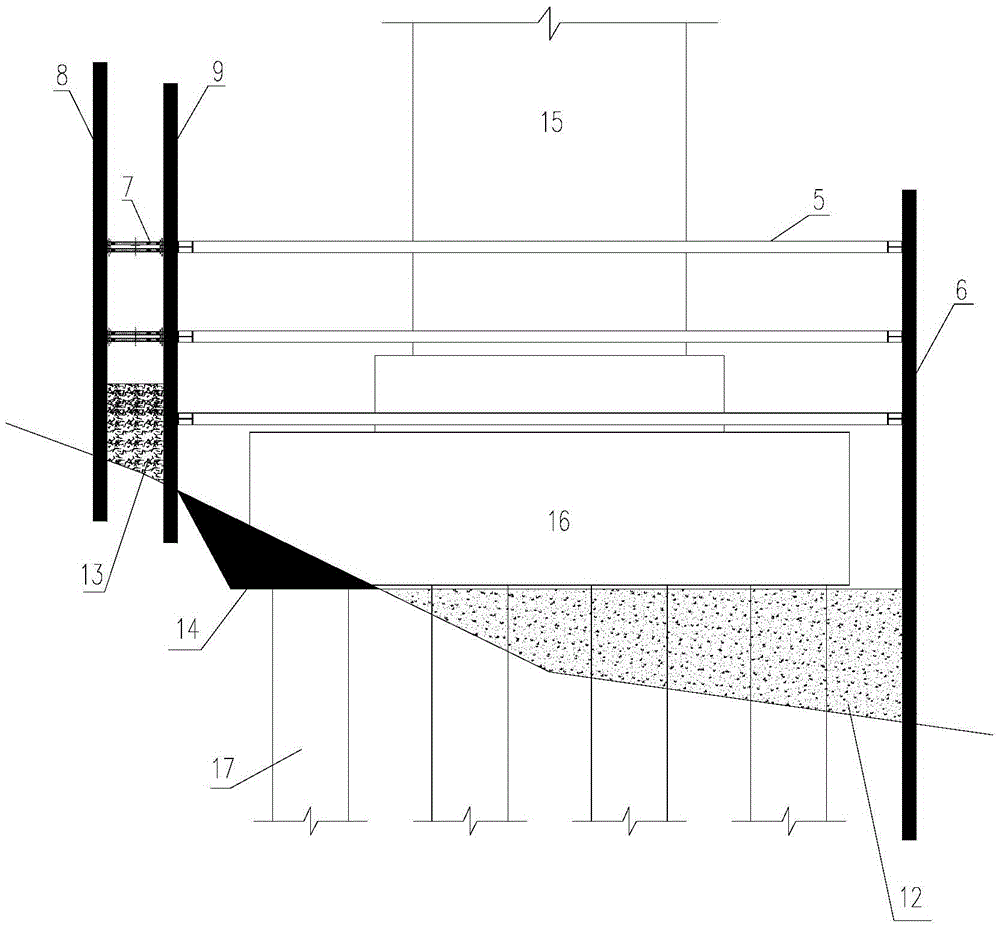

[0027] Step 2: If figure 2 and image 3 A single row of steel sheet piles - deep water steel sheet piles 6 are driven into the deep water side, and double rows of steel sheet piles - shallow water outer steel sheet piles 8 and shallow water inner steel sheet piles 9 are arranged on the shallow water side. Row of steel sheets—11 steel sheet piles inside the slope and 10 steel sheet piles outside the slope; the net distance between the two rows of steel sheet piles is the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com