Method for processing ascending of inner soil of PCC pile

A processing method and pile core technology, which are applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as the rise of pile core soil, and achieve the effects of preventing pile core soil from rising, low cost, and reducing lateral frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

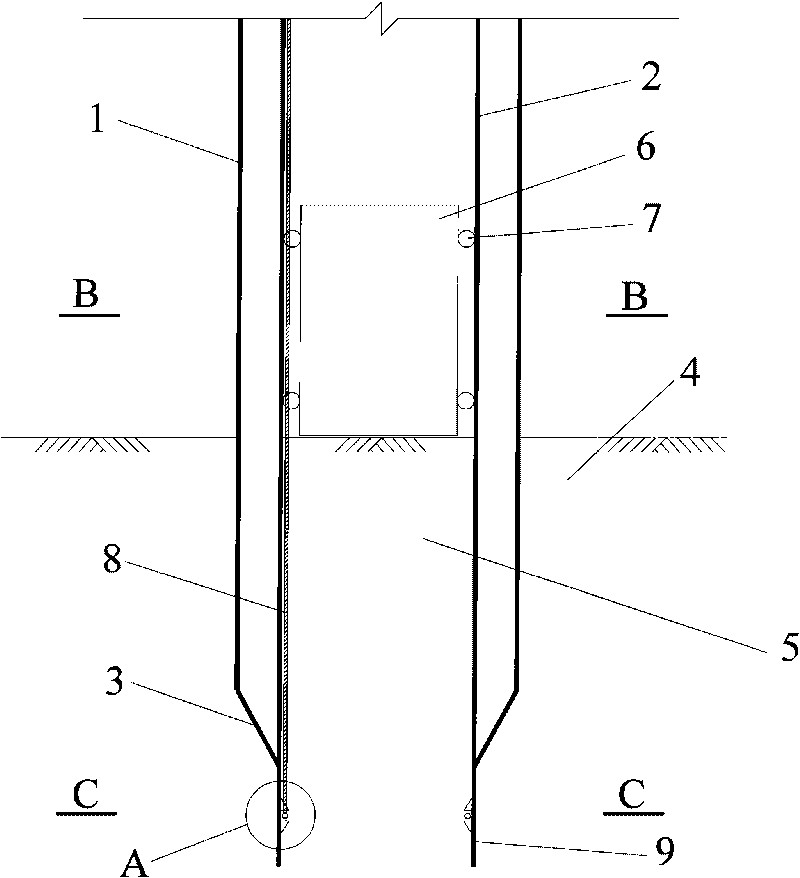

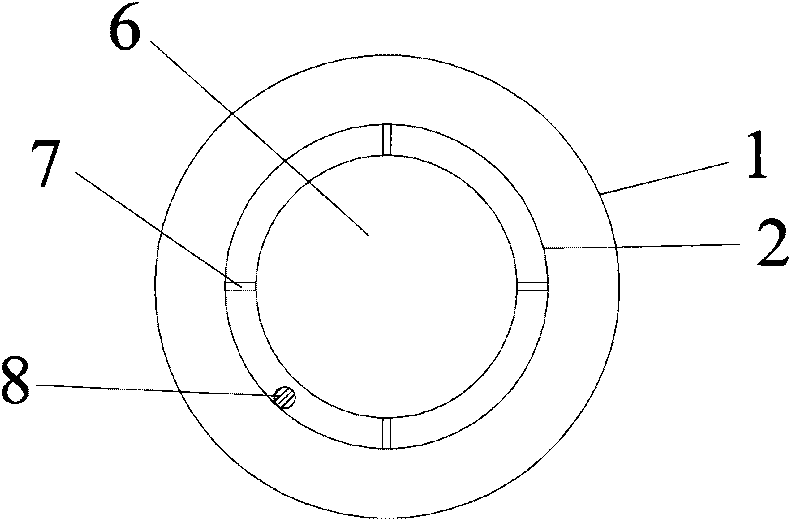

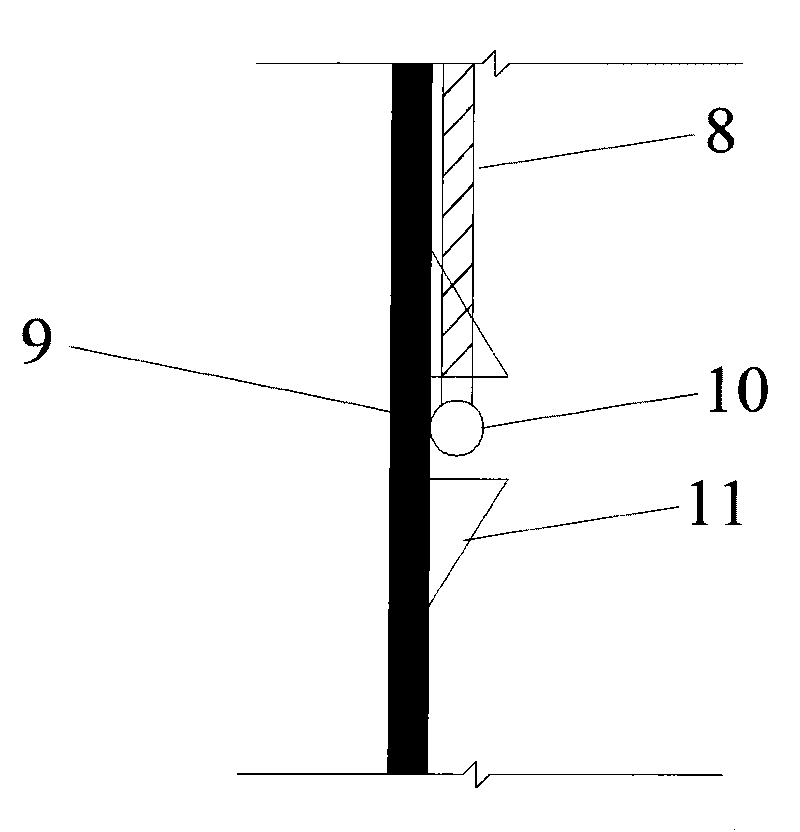

[0019] Such as Figure 1~4 As shown, the cylindrical weight 6 is located inside the pile mold inner pipe 2, and its diameter is slightly smaller than the inner diameter of the pile mold inner pipe. The outer wall of the cylindrical weight 6 has rollers 7 in contact with the inner wall of the inner pipe 2, so that the cylindrical weight 6 can freely slide up and down in the pile mold inner pipe 2. The cylindrical weight 6 can be a prefabricated concrete solid cylinder, or can be formed by injecting water into a hollow cylindrical iron bucket, and its height can be 1.5-2m. Roller 7 is positioned at the outer wall upper part and the lower part of cylindrical weight 6, respectively four symmetrical distributions up and down. Water diversion pipe 8 is welded on the inwall of pile mold inner pipe 2, is made of hollow steel pipe, and the upper end is connected with high-pressure water source, and the lower end is connected with spray pipe 10. The spray pipe 10 is circular and close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com