Culture box for producing tissue engineering skin

A tissue-engineered skin and culture box technology, which can be used in tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of low utilization rate of culture space, difficult to reduce production costs, and difficult to automate operations. , to achieve the effect of automatic or semi-automatic manipulator operation, reducing the probability of pollution and saving culture space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

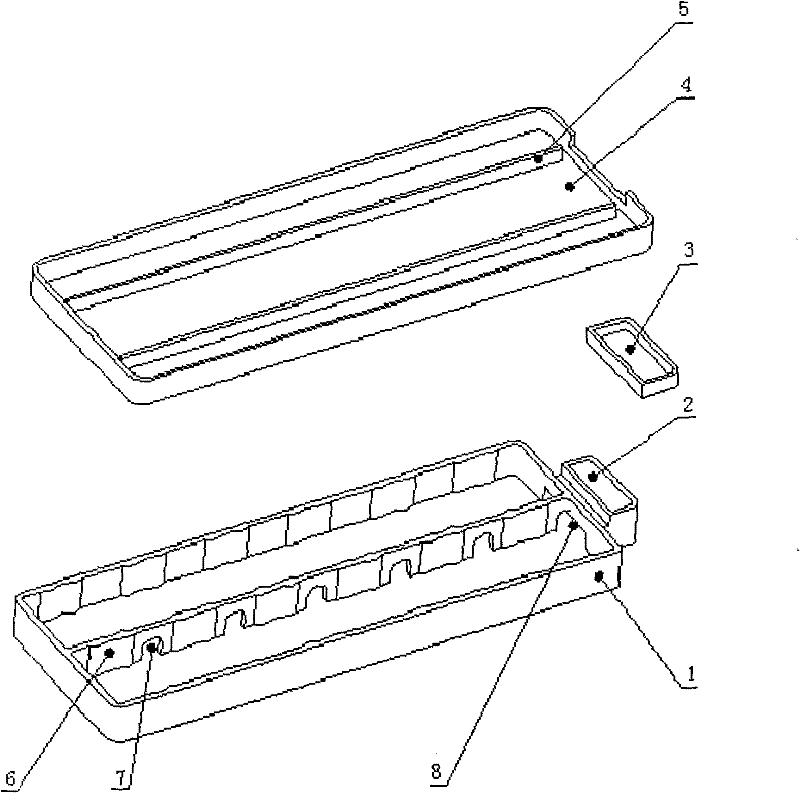

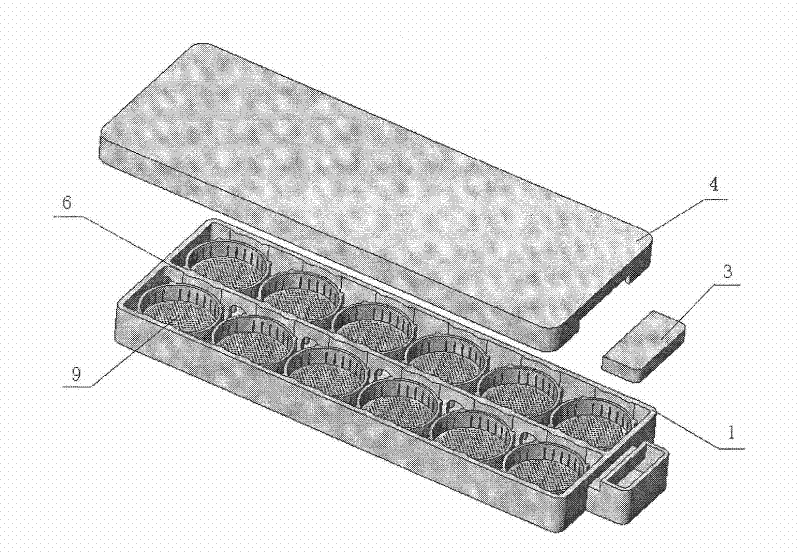

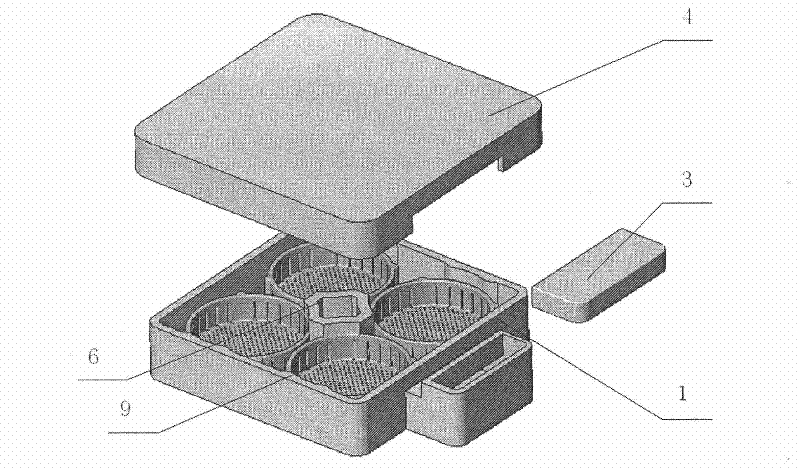

[0020] The specific implementation manner of the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The tissue engineering skin culture box of the present invention can be made of various polymer materials (such as polycarbonate) or metal materials (such as stainless steel) that meet the medical grade requirements, and different processing methods are adopted according to the material, such as machining, injection molding, molding Wait. Its shape and size can be determined according to the type of skin being cultivated.

[0022] Referring to the accompanying drawings, the partitions in the bottom box can be strip-shaped, which divides the box into several areas, and the strip-shaped partitions cooperate with the culture tray, so that the culture tray can be stably placed in it; there are through holes at the bottom of the partition The liquid in the bottom box can be circulated. The partitions c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com