Preparation method of hollow noble metal nanoparticles

A hollow structure, precious metal technology is applied in the field of preparation of hollow structure metal particles, which can solve the problems of high preparation cost, complicated operation process, complicated process control, etc., and achieve the effects of simple operation, high application value and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

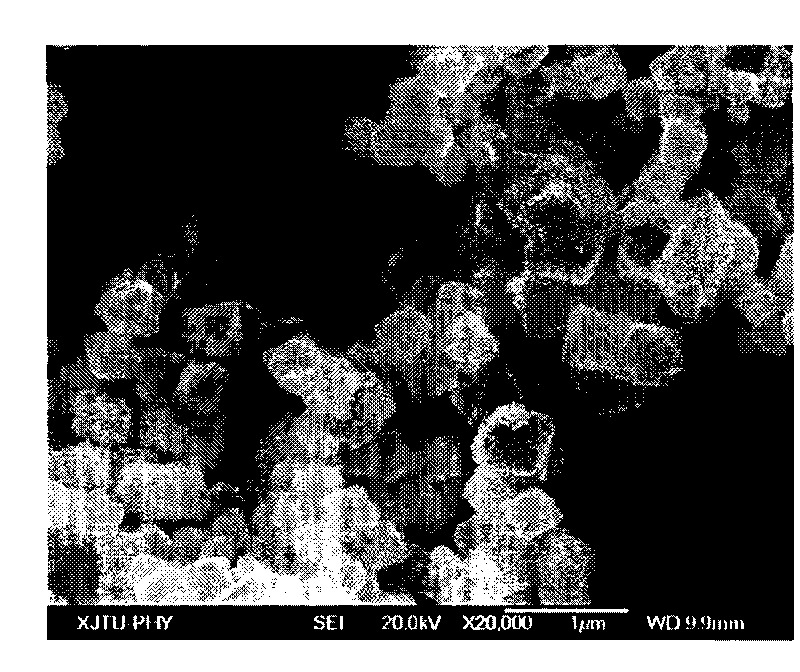

[0014] Example 1: First, take cuprous oxide particles with a particle size of 100nm and add them to a cetyltrimethylammonium bromide solution with a concentration of 20mg / mL to make cetyltrimethylammonium bromide and oxidation The mass ratio of cuprous is 1:1, and the H concentration of 10mg / mL is added to this mixed solution 2 PtCl 6 The solution was mixed and stirred well for 4 hours, wherein the added H 2 PtCl 6 The mass ratio of Pt ions to cuprous oxide in the solution is 2:1; finally, the reacted mixture is centrifuged, and the obtained solid precipitate is washed with ammonia water, and after centrifugation, the following Figure 1a , Figure 1b Shown are hollow Pt nanometal particles with an average particle size of around 100 nm.

Embodiment 2

[0015] Embodiment 2: First, take cuprous oxide particles with a particle size of 50nm and add them to a cetyltrimethylammonium bromide solution with a concentration of 40mg / mL to make cetyltrimethylammonium bromide and oxidation The mass ratio of cuprous is 1:1, and the K concentration of 60mg / mL is added to this mixed solution. 2 PtCl 6 ·6H 2 O solution was mixed and stirred well for 4 hours, to which the K 2 PtCl 6 ·6H 2 The mass ratio of Pt ion to cuprous oxide in the O solution is 4:1; finally, the reacted mixture is centrifuged, and the obtained solid precipitate is washed with ammonia water, and after centrifugation, an average particle size of 50nm can be obtained. Left and right hollow Pt nanoparticles.

Embodiment 3

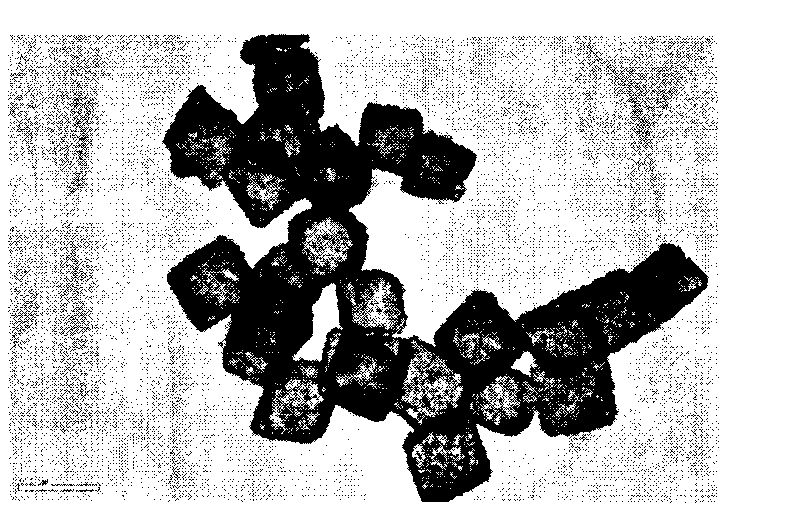

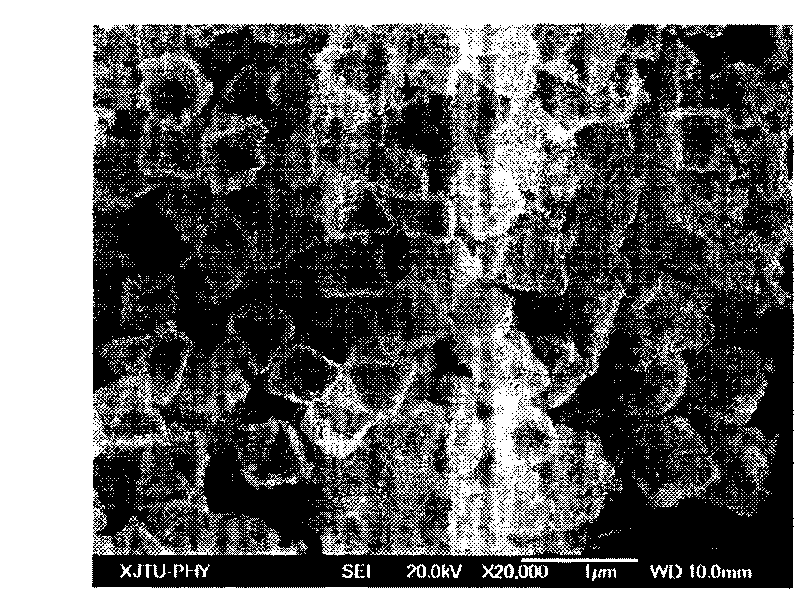

[0016] Example 3: First, take cuprous oxide particles with a particle size of 500nm and add them to a cetyltrimethylammonium bromide solution with a concentration of 10mg / mL to make cetyltrimethylammonium bromide and oxidation The mass ratio of cuprous is 1:1, and the H concentration of 1 mg / mL is added to the mixed solution 2 PdCl 4 The solution was mixed and stirred well for 4 hours, wherein the added H 2 PdCl 4 The mass ratio of Pd ion and cuprous oxide in the solution is 1: 1; Finally, the mixture after the reaction is centrifuged, and the obtained solid precipitate is washed with ammonia water, and after centrifugation, the following Figure 2a , Figure 2b Hollow Pd nanoparticles with an average particle size of about 500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com