Four-machine driven self-synchronizing vibrating screen and structural parameter determining method

A technology of self-synchronized vibration and structural parameters, which is applied in the direction of chemical instruments and methods, filters, motor speed or torque control, etc., can solve the problem of inability to realize the synchronous relationship between the superposition of exciting force, general motors that cannot be installed with vibrators, Problems such as the inability to realize the synchronization of multiple vibration motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

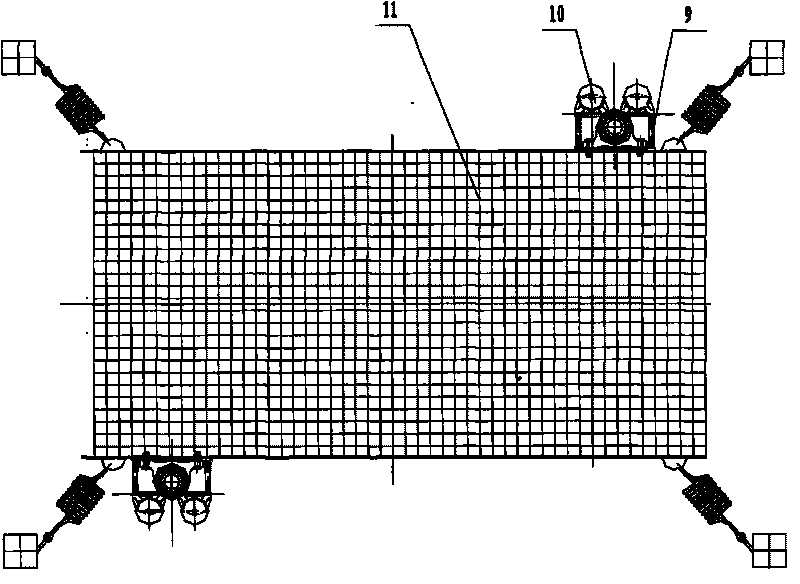

[0721] In this embodiment, a four-machine-driven self-synchronized vibrating screen circular motion structure and a method for determining structural parameters are explained in conjunction with the accompanying drawings

[0722]The four-machine-driven self-synchronizing vibrating screen is shown in Figure 1(a), Figure 1(b) and Figure 1(c), including a screen body 1, a bracket 3, a spring 4, a screen 11 and two symmetrical auxiliary rigid bodies Unit, each auxiliary rigid body unit includes a bearing with seat 2, a bearing chassis with seat 5, a floating shaft 6, a floating limit spring 9, an eccentric block 10 and an auxiliary rigid body, wherein each auxiliary rigid body includes two symmetrical vibration motors 7 And a vibration motor seat 8.

[0723] The connection of the four-machine-driven self-synchronizing vibrating screen is: the bracket 3 is connected to the screen body 1 through the spring 4, and the screen mesh 11 is installed in the screen body; The seat bearing ...

Embodiment 2

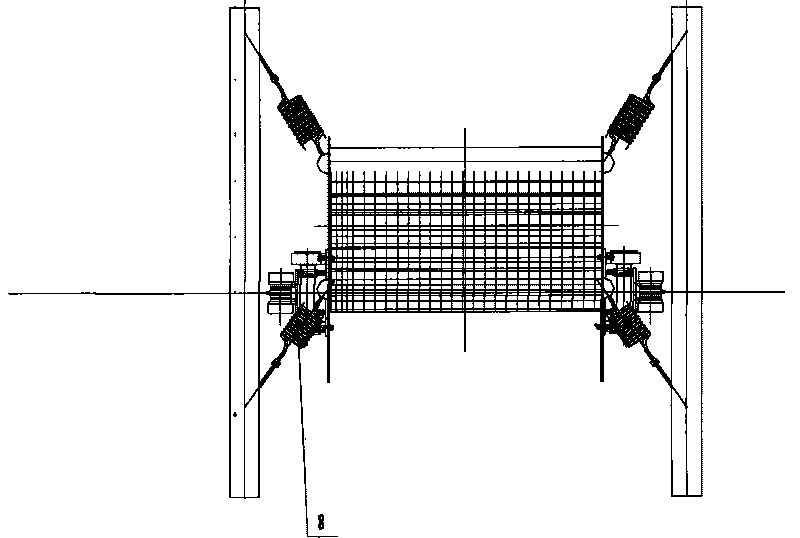

[0791] In this embodiment, a linear motion structure of a four-machine-driven self-synchronized vibrating screen and a method for determining structural parameters are explained in conjunction with the accompanying drawings.

[0792] The four-machine-driven self-synchronizing vibrating screen is shown in Figure 2(a), Figure 2(b) and Figure 2(c), and its structure is the same as the circular motion structure of the four-machine-driven self-synchronizing vibrating screen;

[0793] When the sieve body 1 moves in a straight line, there are two auxiliary rigid body units, and the bearing chassis 5 with seats in the two auxiliary rigid body units are respectively installed on the sieve body 1 with the longitudinal axis as the axis of symmetry.

[0794] The method for determining the structural parameters of the linear motion of the four-machine-driven self-synchronized vibrating screen is the same as the method for determining the structural parameters of the circular motion of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com