Coating anti-wrinkle method of apparel seams

A coating and suture technology, applied in the field of suture anti-wrinkle, can solve the problems of very high skill requirements, affecting the beauty of the suture, and restricting the shape of the suture, so as to simplify the sewing operation, facilitate the sewing operation, and reduce the shape restriction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below will be described in further detail in conjunction with accompanying drawing and specific embodiment: for two cutting pieces or seam bone, all will go through steps such as adhesive agent coating, sewing, pressing to the seam allowance of cutting pieces. For different parts of the shirt, the specific operations are not the same. The following describes the method of making the coated anti-wrinkle seam in detail.

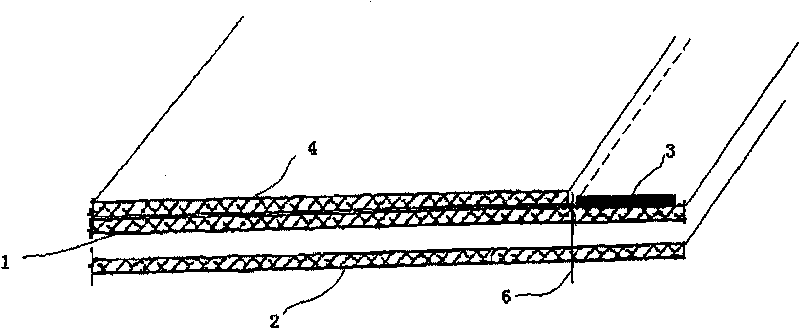

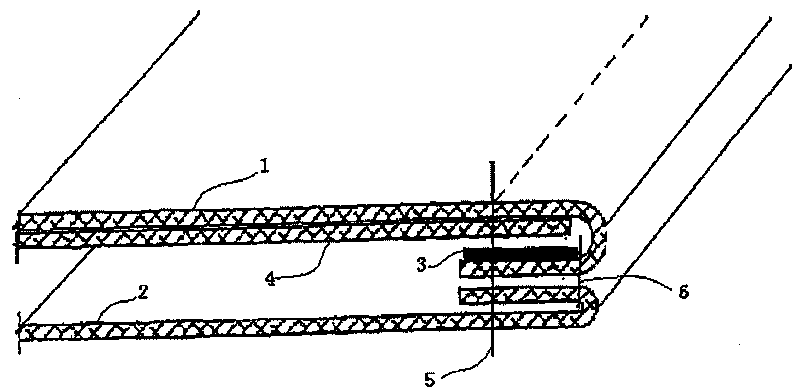

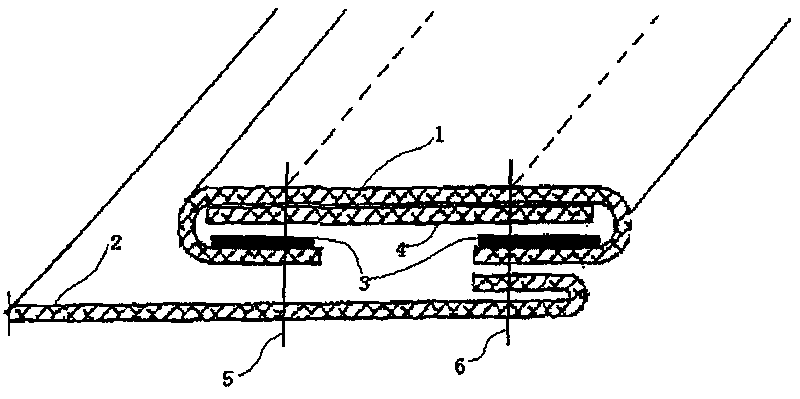

[0034] refer to Figure 1A-Figure 10 B, in the figure: piece 1 is the piece on the appearance of the seam, and piece 2 is the piece on the inside of the seam, hot-melt adhesive coating 3, and piece 4 is a special part (collar , Gan, Jieying, front tube position) the third piece does not affect the operation, sutures 5, 6, 7 are used to fix the pieces to form seams.

[0035] Such as Figure 1A and Figure 1B As shown, in the operation of making a collar or a jacket, piece 1 is a front piece, piece 2 is a bottom piece, and piece 4 is an interlining piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com