X-ray apparatus test device and method for truck tire

A test device and X-ray machine technology, applied in the field of rubber machinery, can solve problems such as tire deformation and affecting the accuracy of X-ray detection data, and achieve the effects of improving centering accuracy, shortening the test cycle, and avoiding input errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

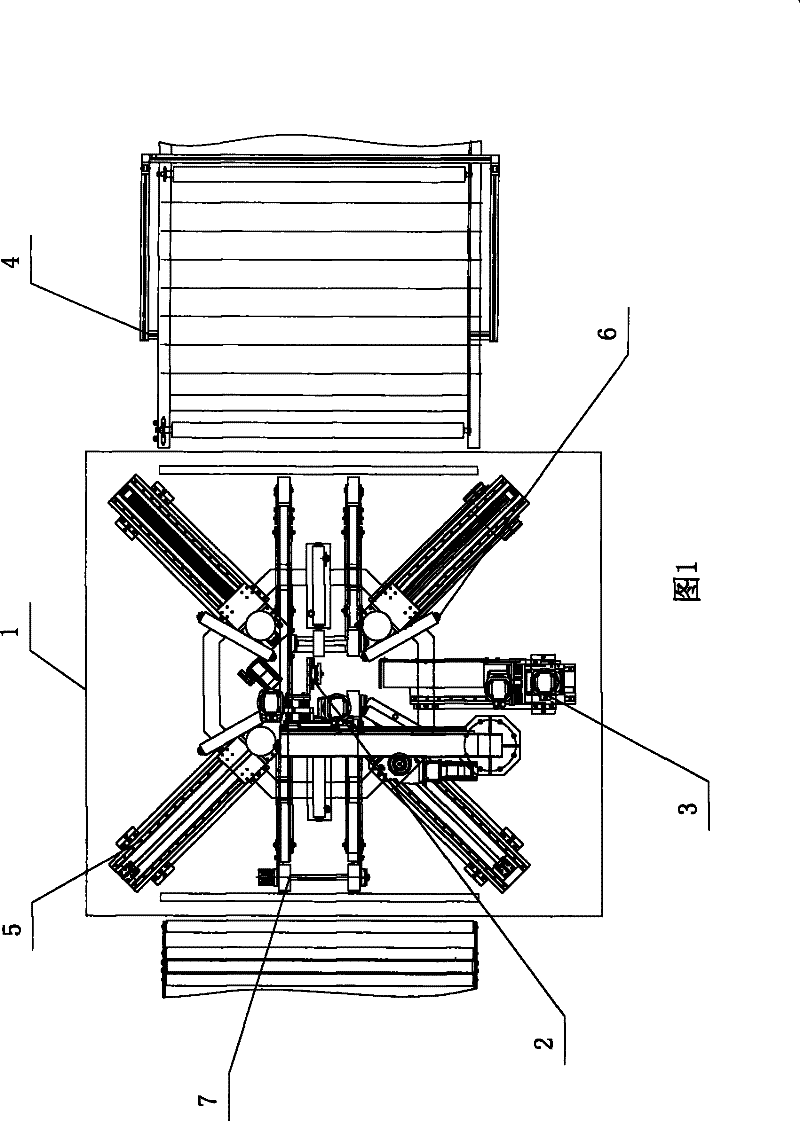

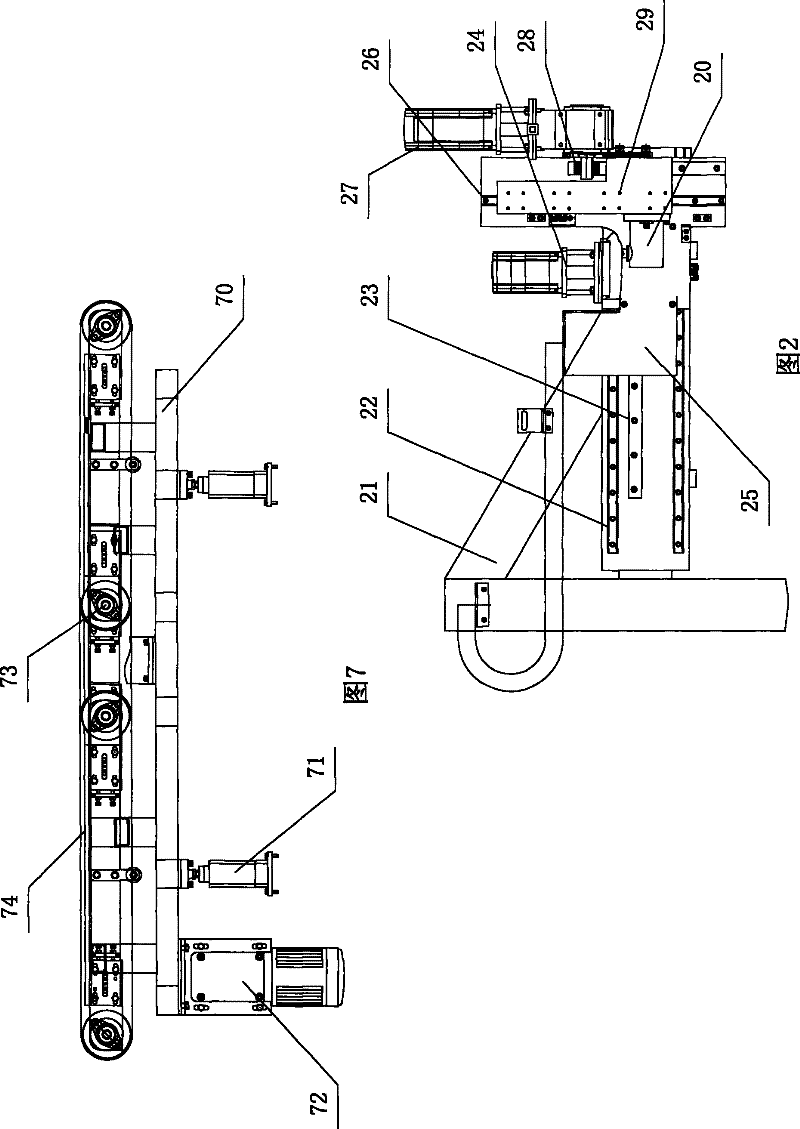

[0060] Embodiment 1, as shown in Figure 1, the truck tire X-ray machine testing device mainly includes an airtight anti-radiation detection room 1, in which an X-ray detection driving device 2, a detector driving device 3, The centering and rotating device 5 , the rotating support device 6 , the internal transmission device 7 of the host machine, and the external dimension measuring device 4 arranged at the entrance of the testing room 1 . in,

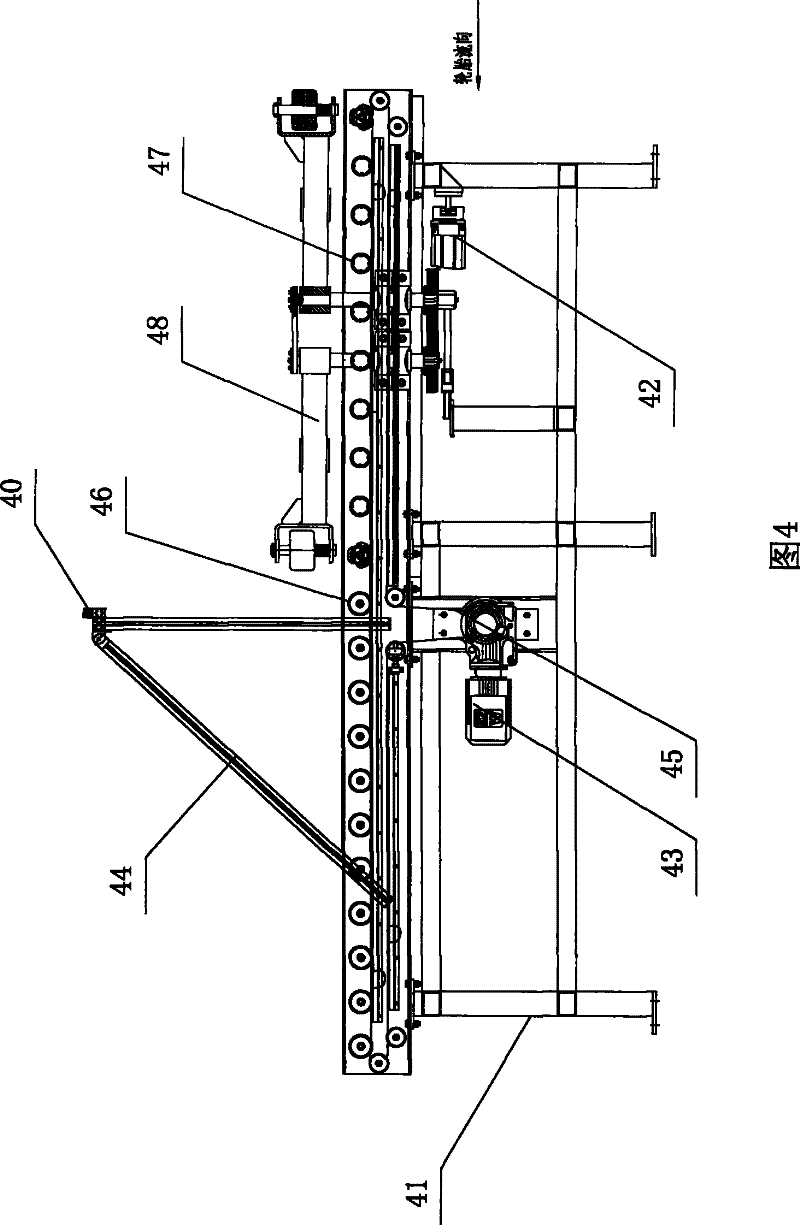

[0061] The X-ray detection drive device 2 is used to drive and position the X-ray tube 20 at the inner center of the tire to be tested and emit X-rays.

[0062] The detector driving device 3 is used to drive and position the detector 30 outside the tire under test in order to receive X-ray detection signals.

[0063] The external dimension measuring device 4 is used to measure the inner diameter, outer diameter and section width of the tire before the X-ray machine test.

[0064] The centering and rotating device 5 is used to locate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com