Settlement test method for embankment filling construction

A test method and embankment technology, applied in the directions of roads, roads, measuring devices, etc., can solve the problems of inaccurate measurement, deflection of the settlement pipe, easy to break, etc., and achieve the effect of good application effect, convenient operation and convenient passage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

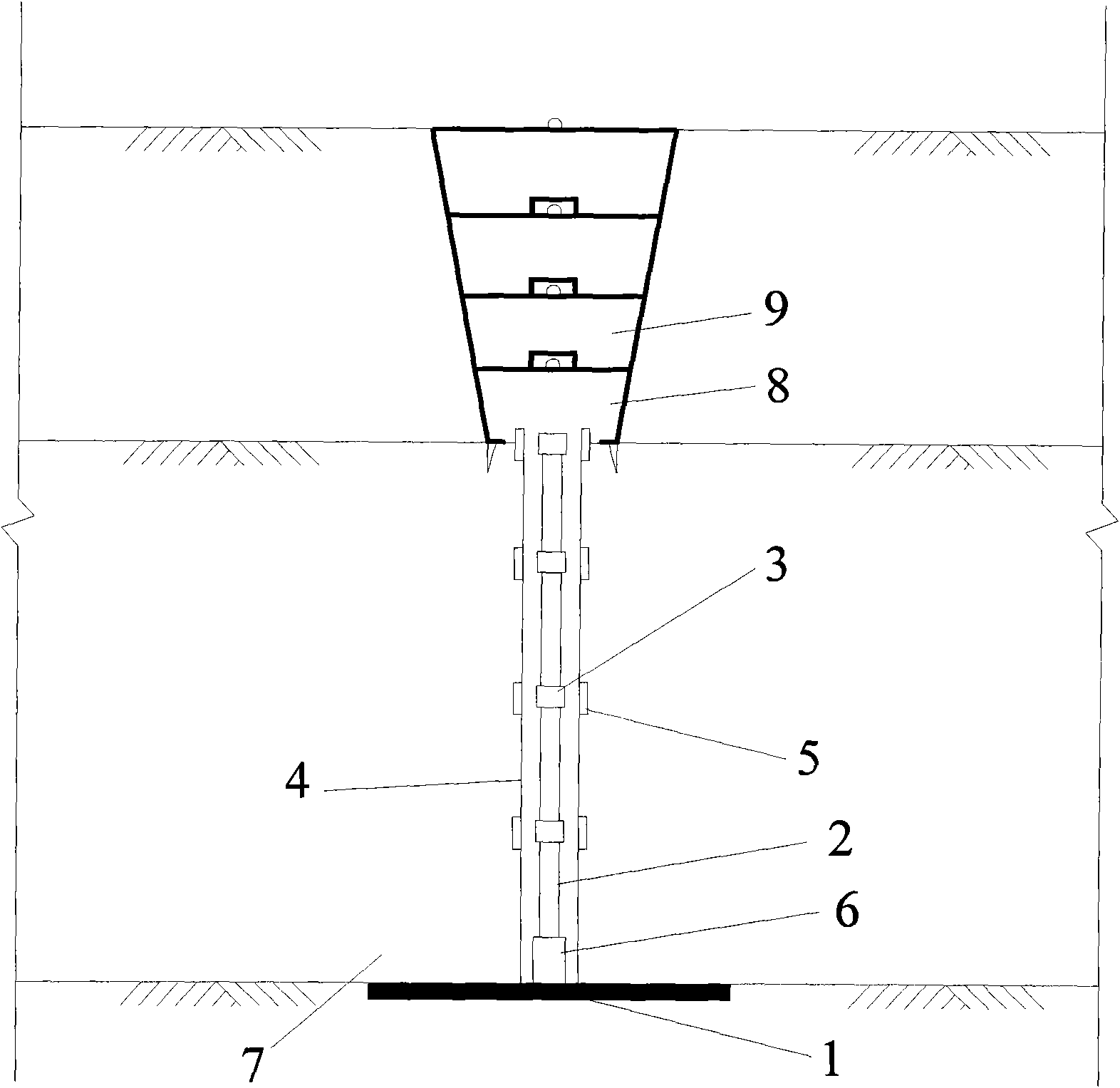

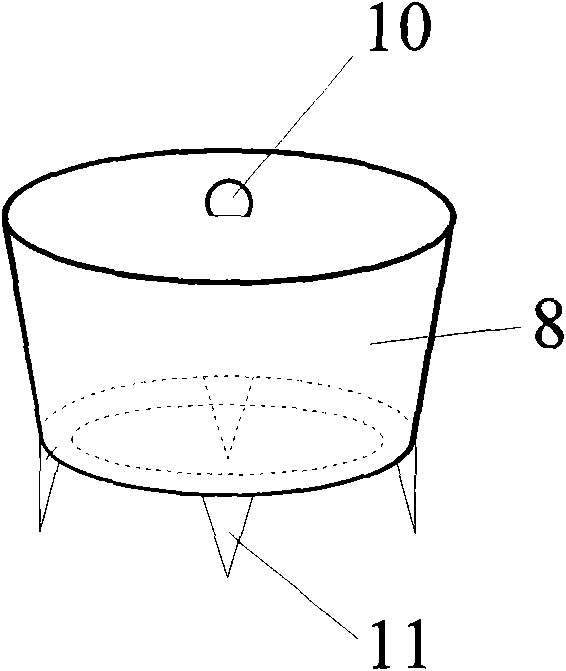

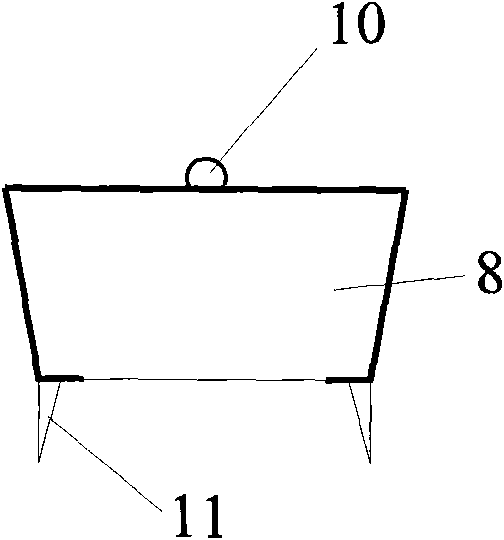

[0028] Such as figure 1 , 2 , 3, and 4 show:

[0029] A settlement test method during embankment filling construction, the monitoring device is composed of a settlement plate 1, a settlement pipe 2, a protective pipe 4, a protective cover 8, and a cushion block 9.

[0030] The settling plate 1 is a square steel plate with a side length of 40cm; the connecting steel pipe 6 is fixed on the settling plate 1, and its height is 10cm; A threaded steel pipe with a diameter of 3 to 5 cm, and the inside of the settlement pipe joint 3 is also threaded, and one section is connected and extended, that is, the settlement pipes 2 of each section are connected to each other through the threaded connection of the settlement pipe joint 3; the protective pipe 4 is a steel pipe or PVC plastic pipe with threads at the upper and lower ends, with a diameter of 5 to 10 cm, connected by a threaded protective pipe joint 5, that is, a section is connected to each other through the protective pipe joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com