Drive wheel speed detection sensor protection structure of power unit

A technology of speed detection and power unit, applied in the direction of speed/acceleration/shock measurement, brake, speed/acceleration/electric shock meter detailed information, etc., can solve the problem of large number of parts and achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

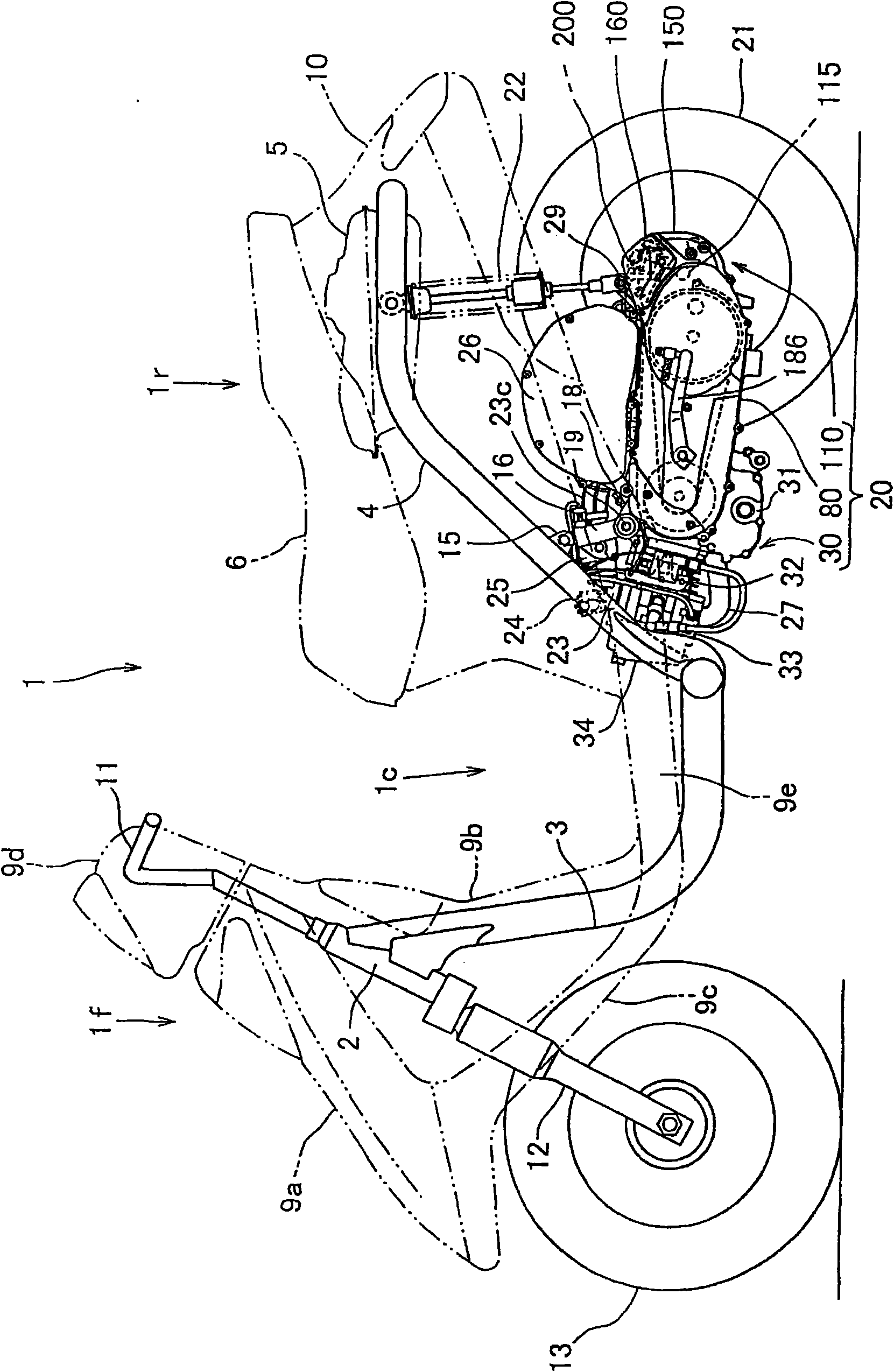

[0060] Below, based on Figure 1~Figure 10 An embodiment of the present invention is described.

[0061] figure 1 It is a side view of a small motorcycle 1 applied to an embodiment of the present invention.

[0062] The vehicle body front portion 1f and the vehicle body rear portion 1r are connected via a low floor portion 1c, and the frame constituting the skeleton of the vehicle body is roughly composed of a down tube 3 and a main pipe 4.

[0063] That is, the down pipe 3 extends downward from the head pipe 2 of the front portion 1f of the vehicle body. The down pipe 3 is bent horizontally at the lower end and extends in the lower direction of the bottom plate portion 1c rearward. A pair of left and right main pipes are connected to the rear end of the down pipe 3 4. The main pipe 4 stands obliquely rearward from the connection part, bends horizontally at a predetermined height and extends backward.

[0064] A fuel tank 5 and the like are supported by this main pipe 4, and a seat 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com