A cylindrical steel conveying vehicle with a protective device

A protective device and cylindrical technology, applied in the field of cylindrical steel conveying vehicles, can solve the problems of physical exertion and increased labor, and achieve the effects of convenient placement, reduced labor, and improved handling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

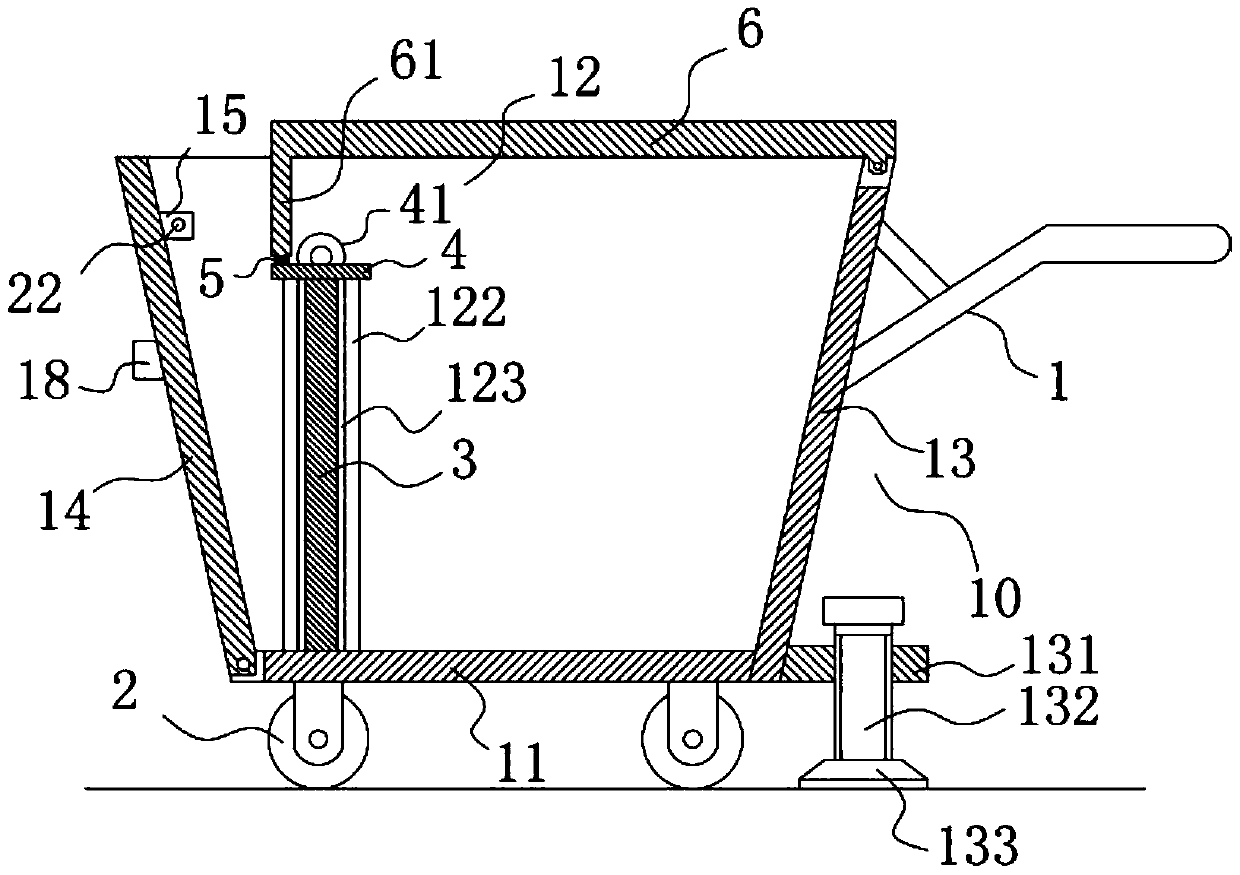

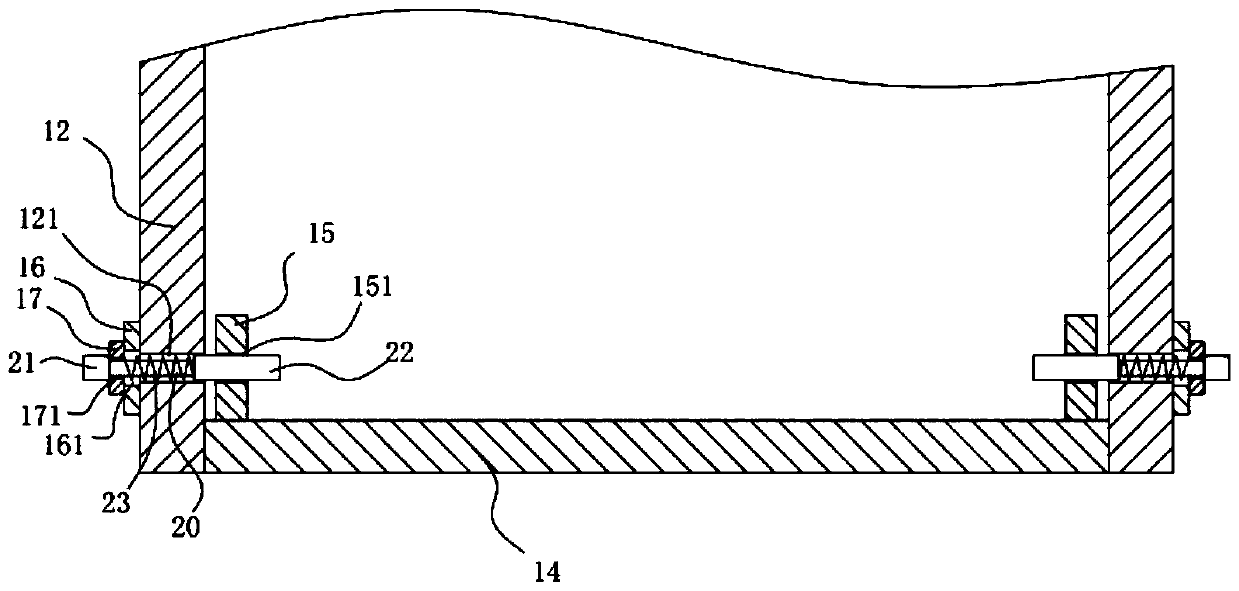

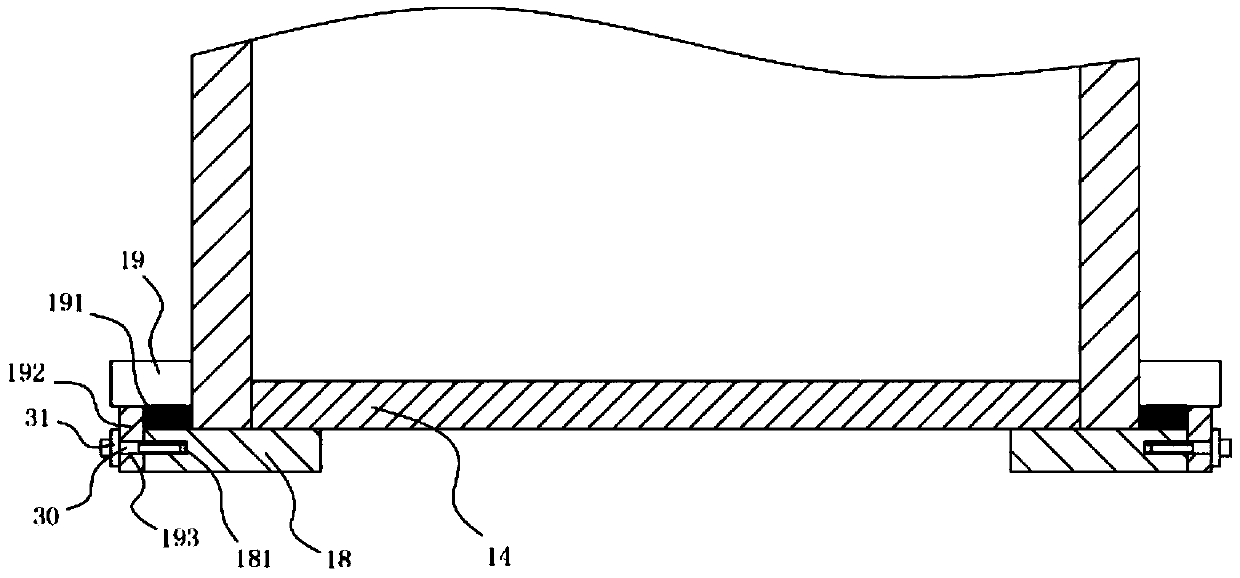

[0020] Example: see Figure 1 to Figure 4 As shown, a cylindrical steel conveying vehicle with a protective device includes a vehicle frame 10, the bottom of which is hinged with wheels 2, and the vehicle frame 10 includes a bottom plate 11, and side plates 12 are welded and fixed on both sides of the bottom plate 11 , the rear portion of the base plate 11 is welded and fixed with a rear plate body 13, the two sides of the rear plate body 13 are welded and fixed on the two side plates 12, the bottom of the front plate body 14 is hinged on the front portion of the base plate 11 through a hinge shaft, and the front plate The body 14 is between the two side plates 12;

[0021] There are vertical track blocks 122 on the front inner side walls of the two side plates 12, and the two side parts of the baffle plate 3 are inserted in the vertical chute 123 that is provided on the corresponding vertical track block 122. The top surface is fixed with an upper baffle plate 4, the front p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com