Breather device for engine

A ventilation device and engine technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as oil immersion into the interior of the ventilation chamber, and achieve the effect of improving the degree of freedom and preventing the freezing of blow-by gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

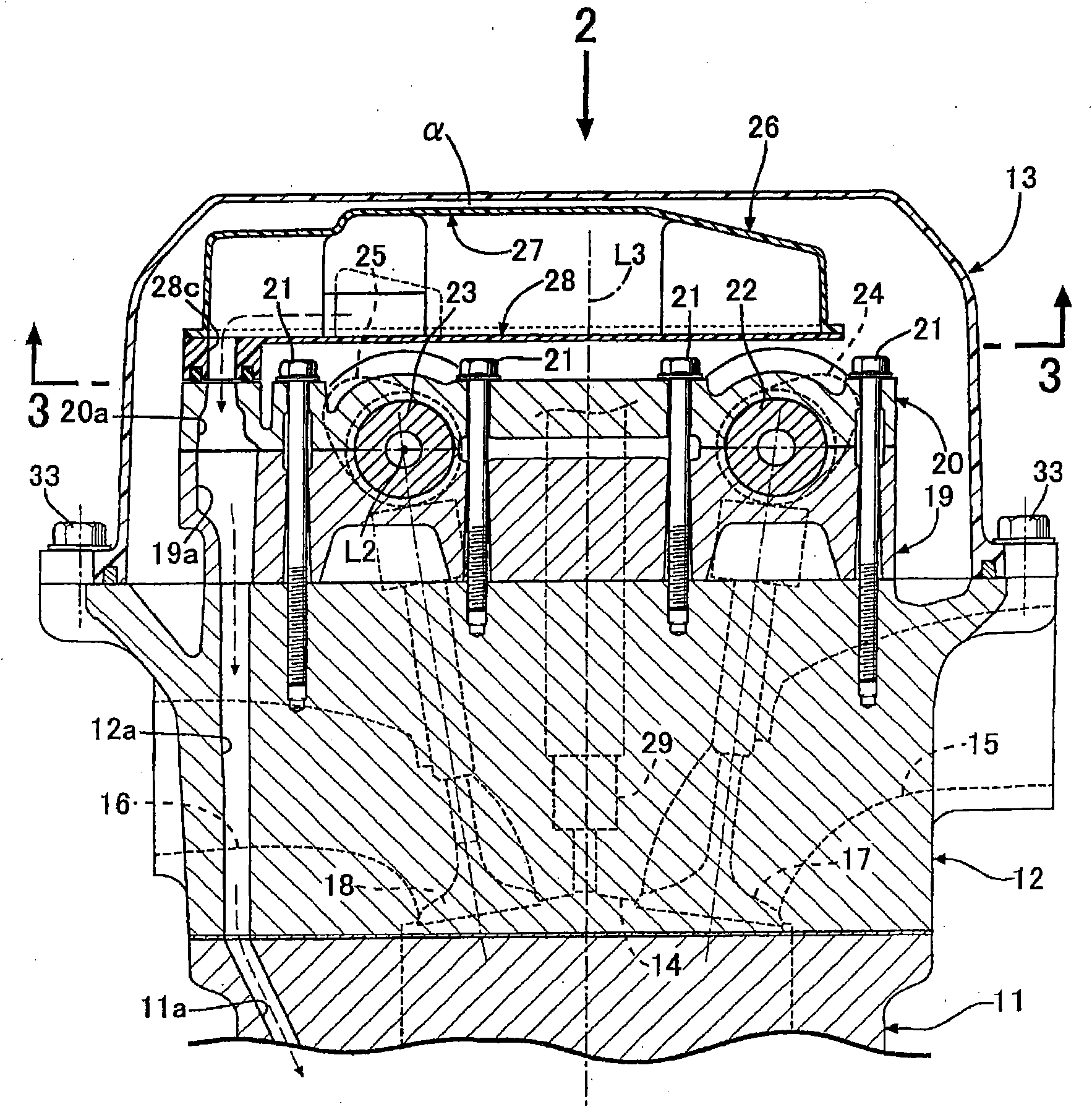

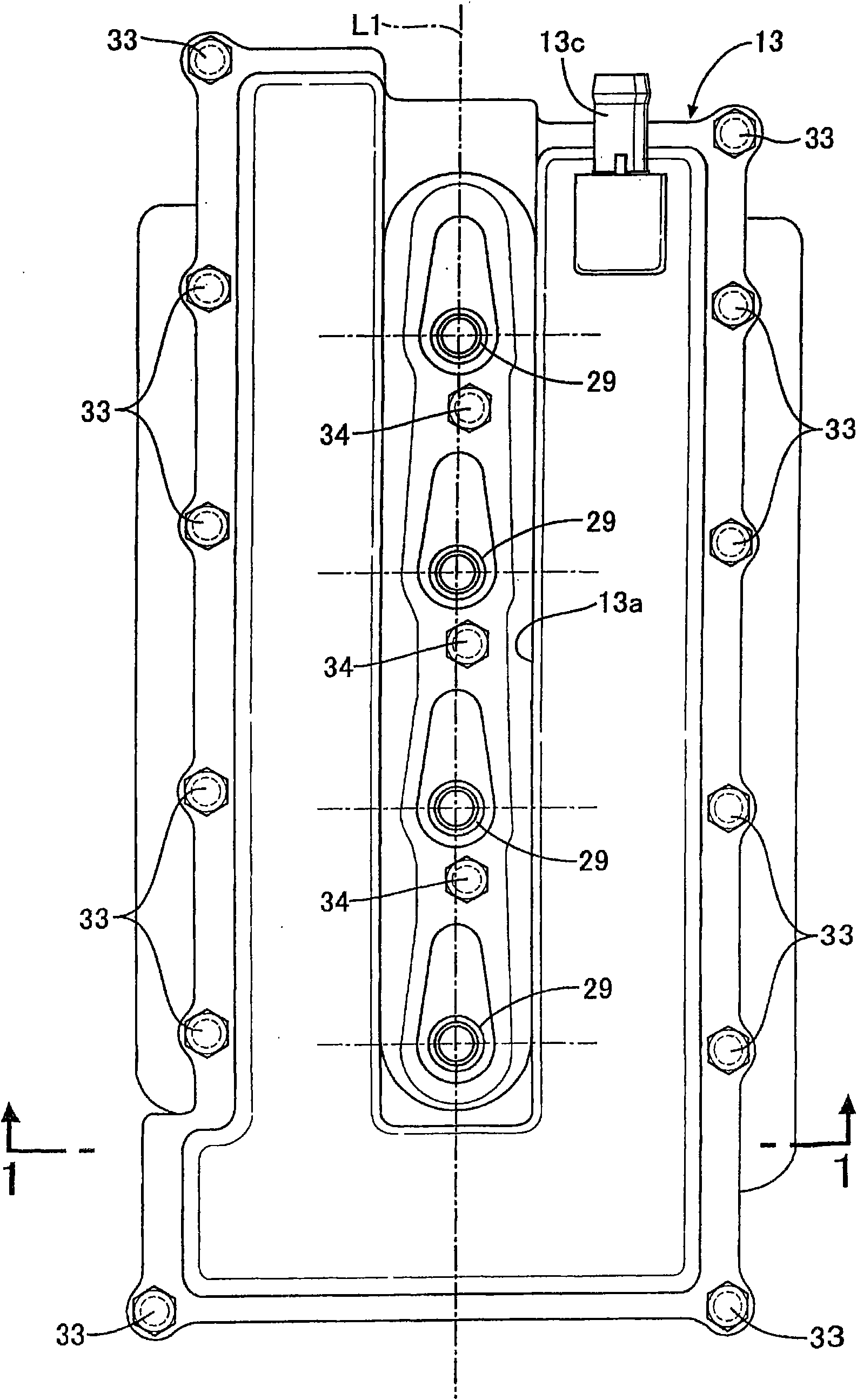

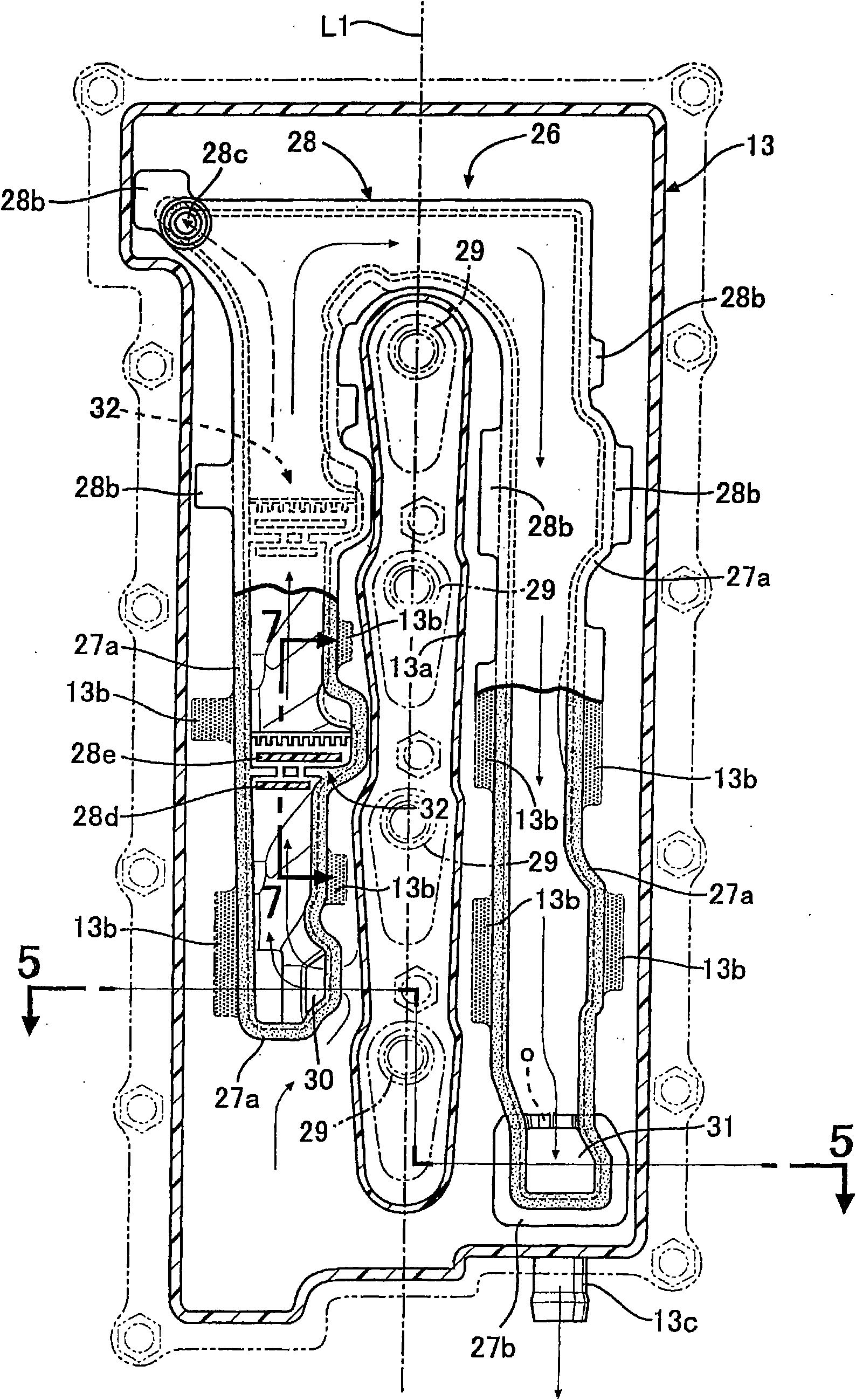

[0030] Figure 1 to Figure 8 Embodiments of the present invention are shown.

[0031] Such as figure 1 As shown, the cylinder head 12 is combined on the upper end of the cylinder block 11 of the in-cylinder injection fuel engine, and the cylinder head cover 13 is combined on the upper end of the cylinder head 12 . In this specification, the vertical direction is defined with the cylinder block 11 side as the lower side and the cylinder head cover 13 side as the upper side.

[0032] A combustion chamber 14, an intake port 15 and an exhaust port 16 connected to the combustion chamber 14 are formed in the cylinder head 12. The intake port 15 is opened and closed by the intake valve 17, and the exhaust port 16 is opened and closed by the exhaust valve 18. close. The camshaft holder 19 and the cover 20 overlap and are fastened on the upper surface of the cylinder head 12 by a plurality of bolts 21 . Between the retainer 19 and the cover 20 , an intake cam 24 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com