Pallet

一种托盘、内加强筋的技术,应用在刚性容器、容器、包装等方向,能够解决难吹塑成型、破坏等问题,达到弯曲强度大、防止破坏、伸长量小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

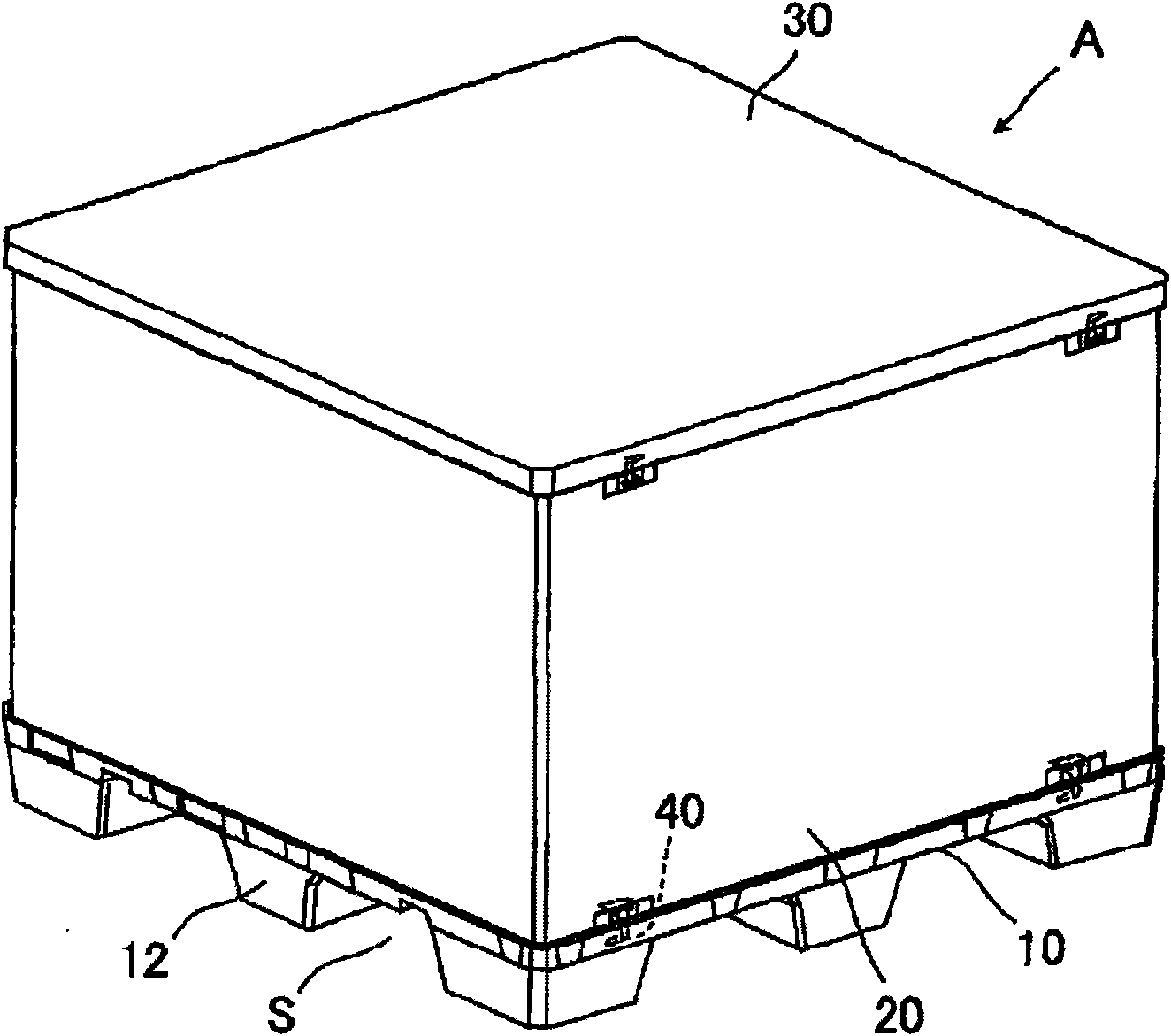

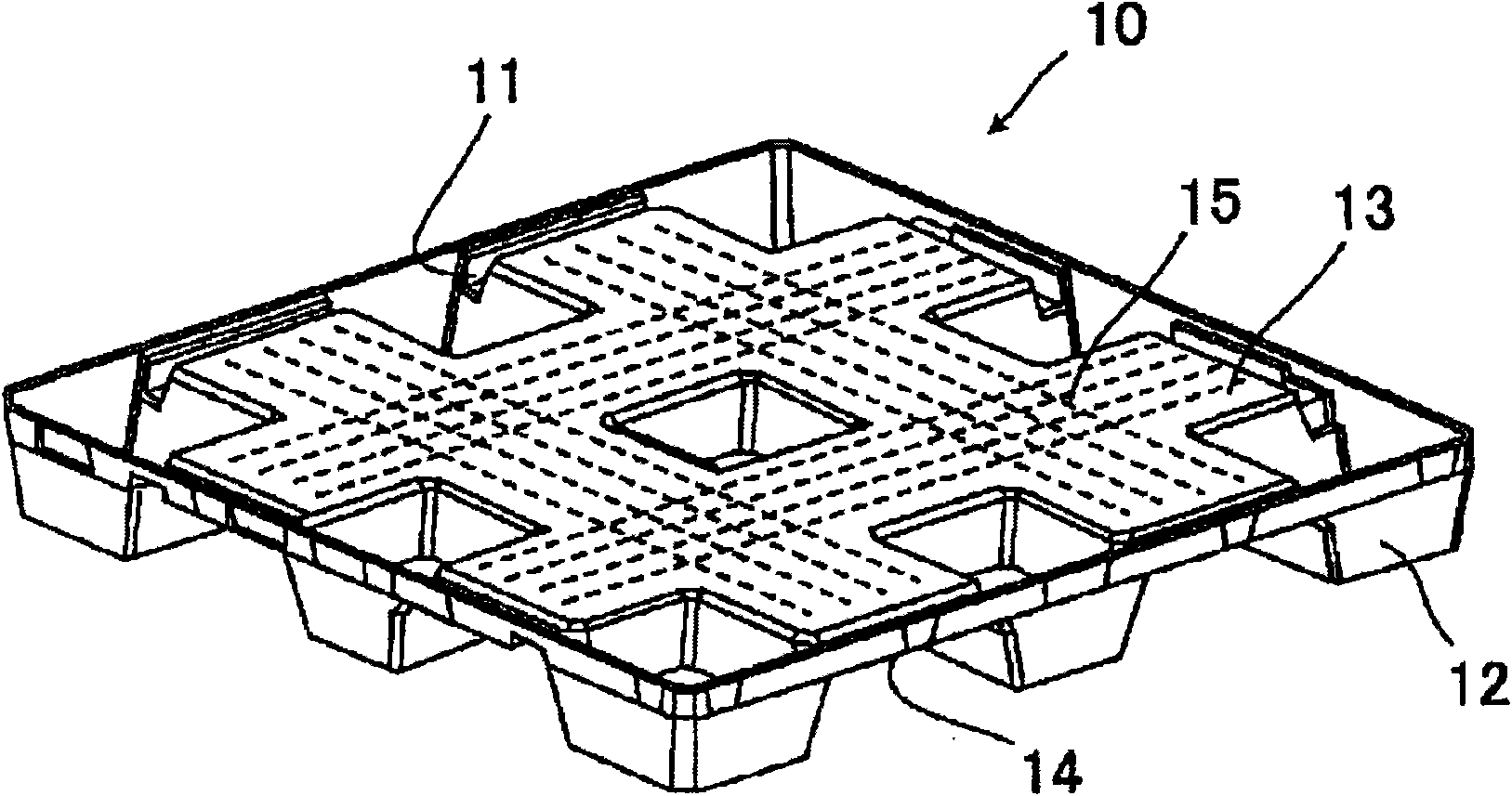

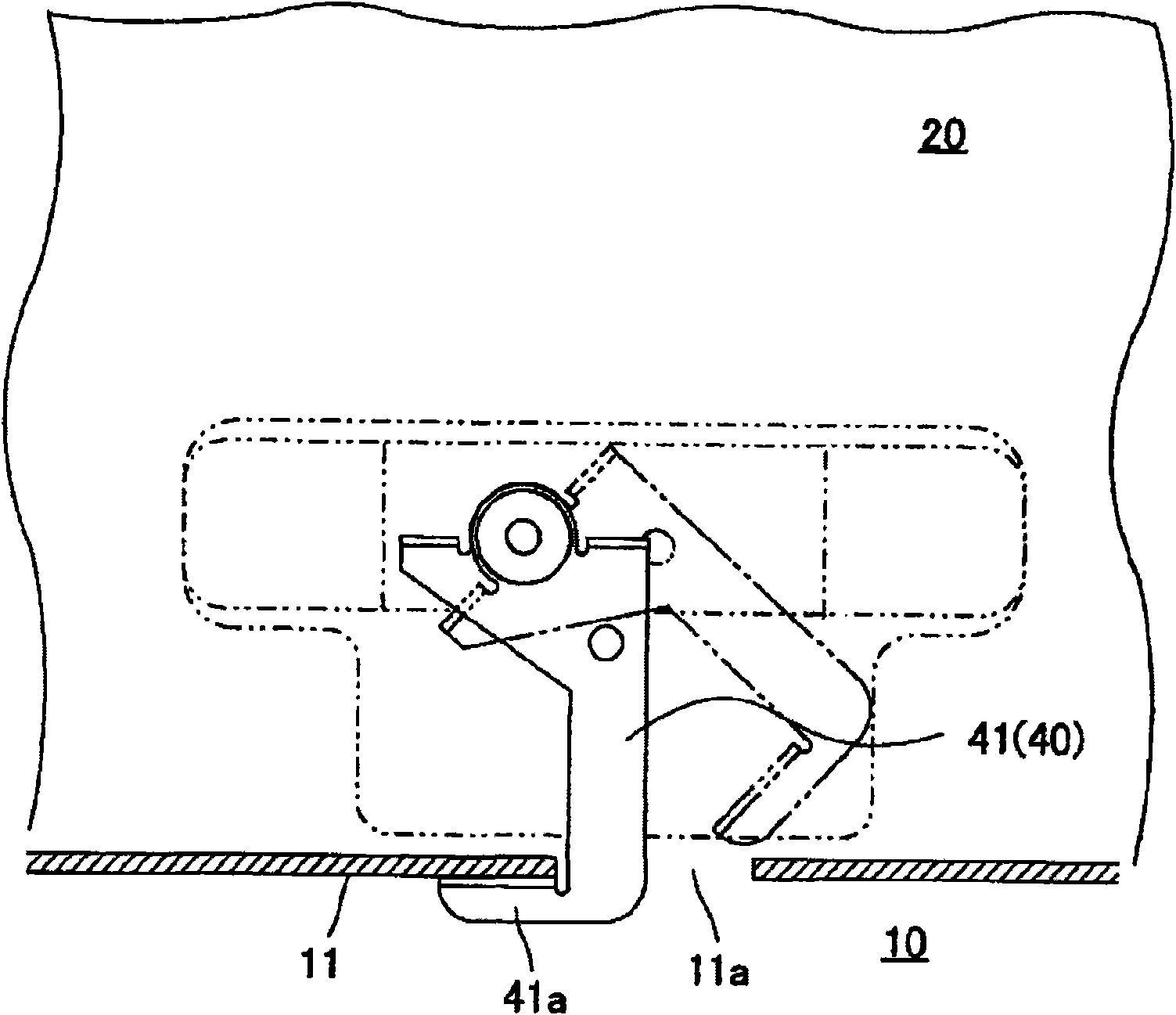

[0065] An embodiment of the present invention will be described with reference to the drawings. figure 1 It is an explanatory drawing which shows an example of the shipping container which uses the pallet of this Example. figure 2 It is an explanatory drawing which shows the tray of this Example. First, the shipping container A in which pallets are assembled will be described. Such as figure 1 As shown, the transportation container A is composed of the pallet 10 of this embodiment as the bottom of the transportation container A, the sleeve 20 forming the side wall of the transportation container A, and the cover part 30 as the cover of the transportation container A.

[0066] The tray 10 has a rectangular shape, and an unillustrated placement groove is formed around the tray 10 . The side walls of the shipping container A are formed by vertically setting and fixing sleeves in placement grooves formed on the pallet 10 . In addition, the cover portion 30 is also formed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com