Baffle plate with plated film

A technology of baffles and film materials, applied in optical components, optics, instruments, etc., can solve the problem of uncontrollable film material output and achieve the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

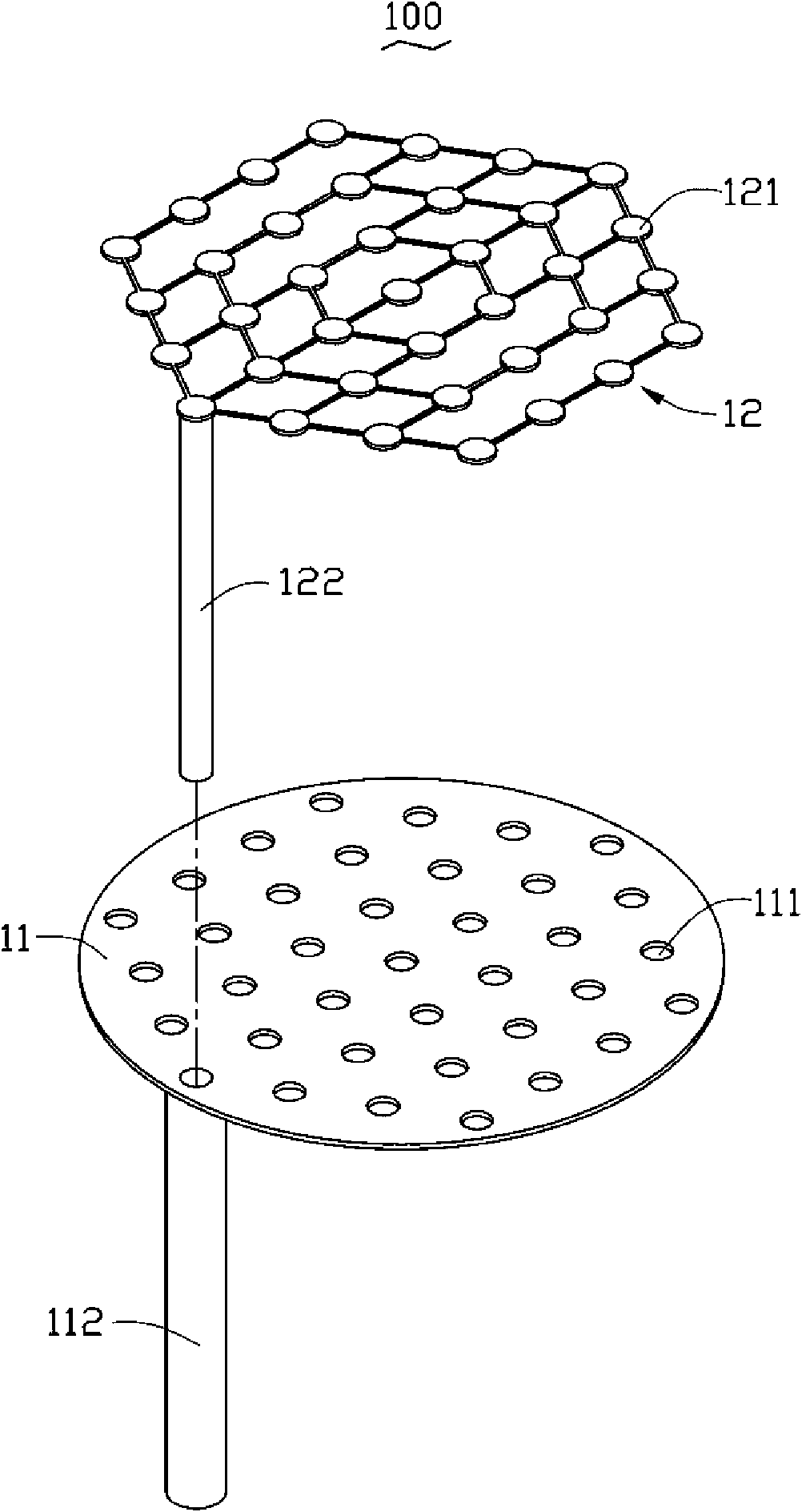

[0011] See figure 1 and figure 2 , the coating baffle 100 provided by the embodiment of the present invention includes a first baffle 11 and a second baffle 12 .

[0012] The first baffle 11 is provided with a plurality of through holes 111 . Preferably, in this embodiment, the plurality of through holes 111 are arranged in an array.

[0013] The second baffle 12 includes a plurality of shielding units 121 , and the plurality of shielding units 121 are connected to each other and matched with the second plurality of through holes 111 respectively. The coating baffle 100 is arranged between the film material and the substrate to be coated, and the first baffle 11 and the second baffle 12 can move relative to each other so that the plurality of shielding units 121 cover the first baffle respectively. The plurality of through holes 111 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com