Slotted core ribbon cable

A skeleton and cable technology, which is applied in the field of cables with skeletons, can solve the problems of affecting the current-carrying performance of conductors, reducing the cross-section of conductors, and easy cracking of insulating layers, etc., and achieves the effects of simple structure, reduced cross-section and long product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

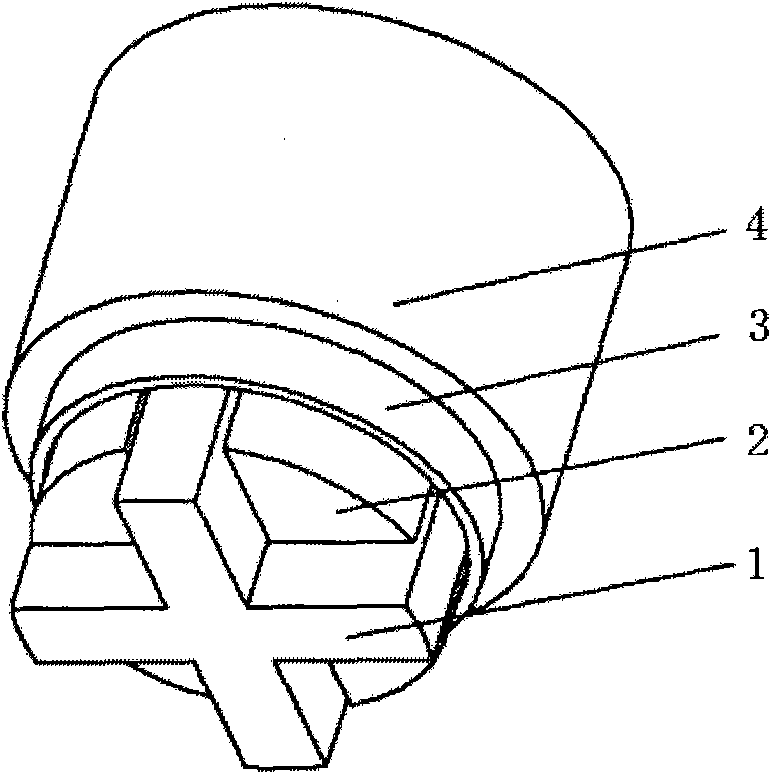

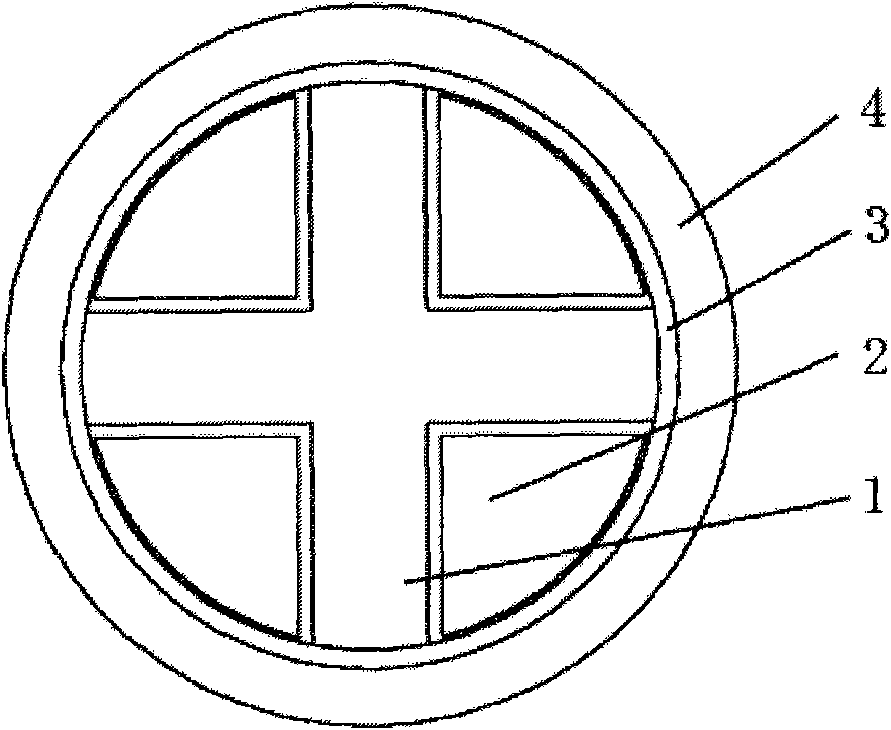

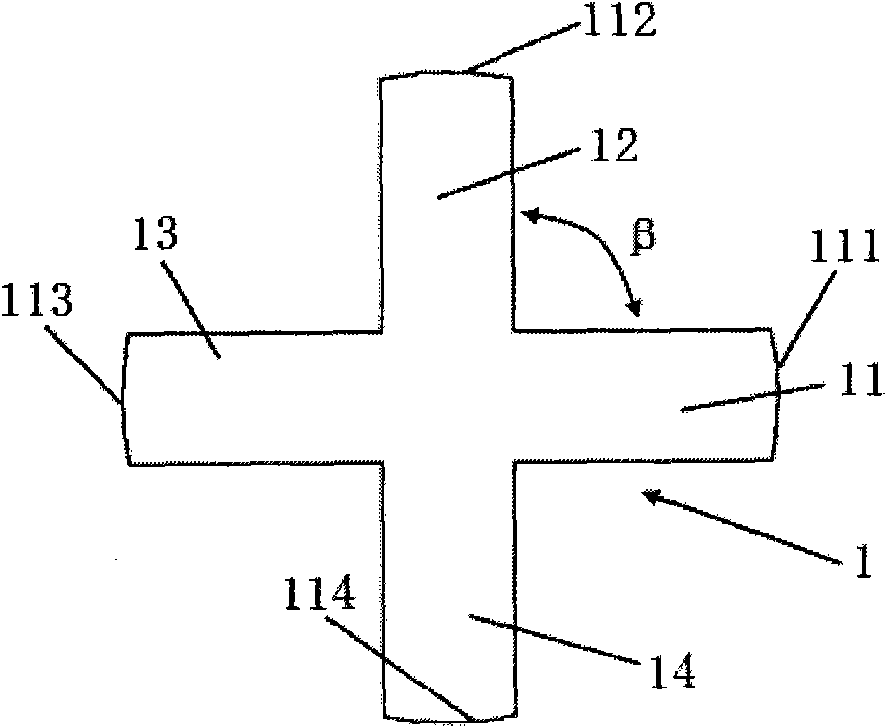

[0029] See figure 1 , figure 2 with image 3 , a skeleton cable, which includes an outer sheath 4 and a conductor 2, and the conductor 2 is located in the outer sheath 4; it is characterized in that: the outer sheath 4 also includes a skeleton 1, and the skeleton 1 separates the inside of the outer sheath into four mutual In the fan-cylindrical space that is not connected, the conductor 2 is located in the fan-cylindrical space; any two conductors do not touch each other; on the cross-section of the skeleton 1, the skeleton is composed of bone leaves (11, 12, 13, 14), and the skeleton The outer edges of the lobes are arcs (111, 112, 113, 114), and the edges of the two lobes connected to the arcs on any lobes are parallel to each other, and an angle β is formed between adjacent lobes; the value of β is 90 degrees; the arcs (111, 112, 113, 114) on the outer edge of the bone leaf are of equal curvature and the centers of the arcs coincide with each other and the lengths of the...

Embodiment 2

[0031] See Figure 4 , basically the same as the implementation example 1, the difference is that there is no protective layer 3.

Embodiment 3

[0033] See Figure 5 , basically the same as the implementation example 2, the difference is that: the skeleton 1 is also provided with a reinforcing member 5; the reinforcing member 5 is metal or non-metallic; preferably aramid yarn or glass fiber is added to a plastic rod or steel wire; the introduction of the reinforcing member , making the entire cable more resistant to stretching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com