Method for measuring flame propagation velocity of Bunsen burner during combustion process of gaseous fuel

A technology of flame propagation velocity and integral image, which is applied to devices using optical methods, etc., can solve problems such as low accuracy, and achieve the effects of improved accuracy, simple measurement process, and error elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

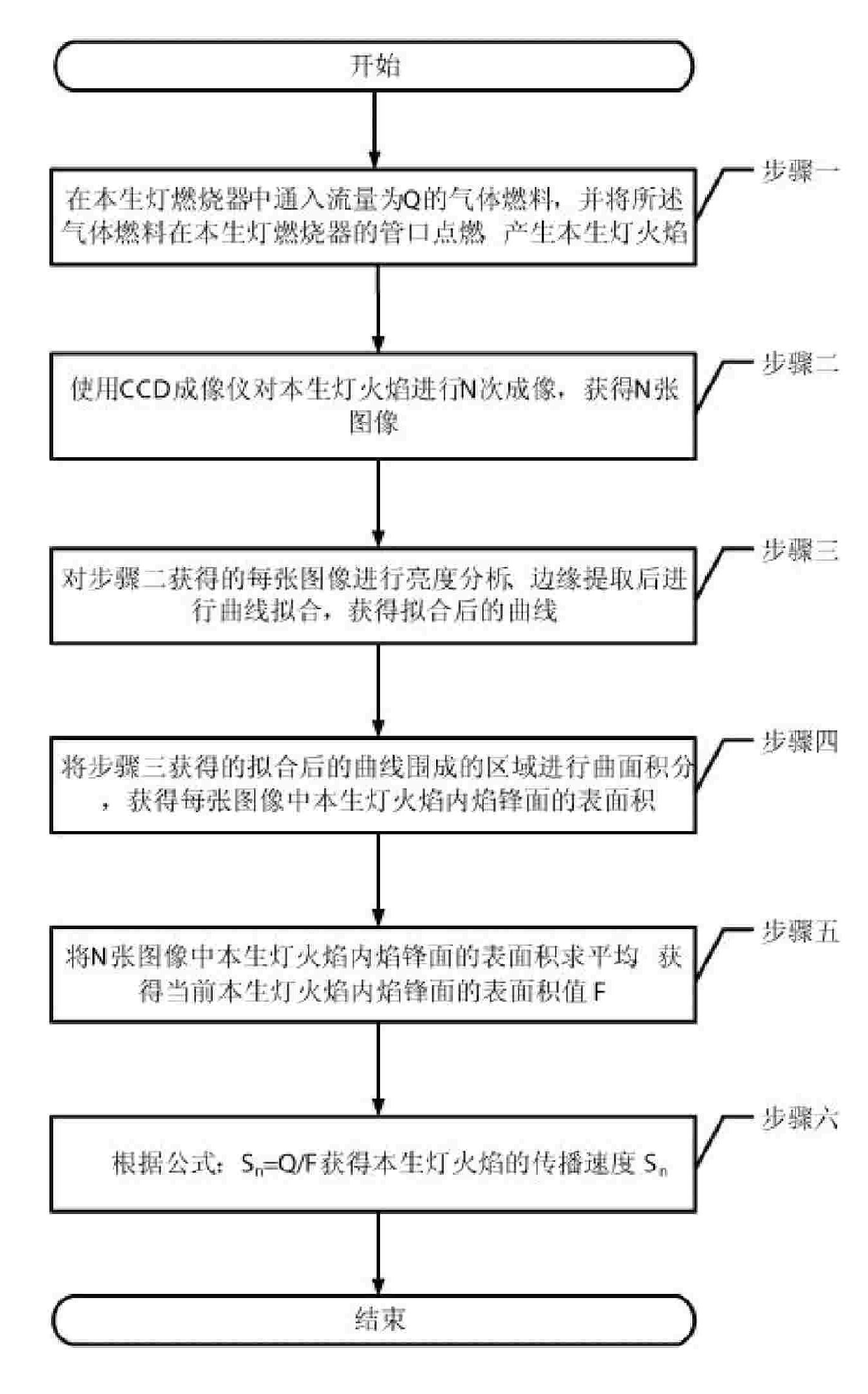

[0017] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, the measurement method of the flame propagation velocity of the gaseous fuel based on surface integral image processing technology in the Bunsen burner combustion process, it is realized by the following steps:

[0018] Step 1, in the Bunsen burner burner 16, feed the gas fuel with a flow rate of Q, and ignite the gas fuel at the mouth of the Bunsen burner burner 16 to generate a Bunsen burner flame;

[0019] Step 2, adjust the focal length between the Bunsen burner flame and the CCD imager 17 through the focusing telescope 18 arranged at the optical input end of the CCD imager 17, and then use the CCD imager 17 to perform N times of imaging on the Bunsen burner flame to obtain N sheets image;

[0020] Step 3, perform brightness analysis on each image obtained in step 2, and perform curve fitting after edge extraction to obtain a fitted curve;

[0021] Step 4, performing surface ...

specific Embodiment approach 2

[0027] Embodiment 2. The difference between this embodiment and the method for measuring the flame propagation velocity of the gaseous fuel in the Bunsen burner combustion process based on the surface integral image processing technology described in the embodiment 1 is that the gaseous fuel is used in this embodiment. The method for measuring the speed of flame propagation in the process of burning a lamp flame is characterized in that the gaseous fuel is a mixed fuel of methane, oxygen and nitrogen.

specific Embodiment approach 3

[0028] Specific embodiment three, the difference between this specific embodiment and the method for measuring the flame propagation velocity of the gaseous fuel based on surface integral image processing technology described in specific embodiment two during the Bunsen burner combustion process is that the volume ratio of the methane is 6%~50%, the volume ratio of oxygen is 13%~70%, and the volume ratio of nitrogen is 10%~80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com