Bearing retainer and machining technique thereof

A technology of bearing retainer and processing technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of greatly limited working temperature, low operating temperature, and high comprehensive cost, so as to avoid material waste cost, Effect of avoiding scrap and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

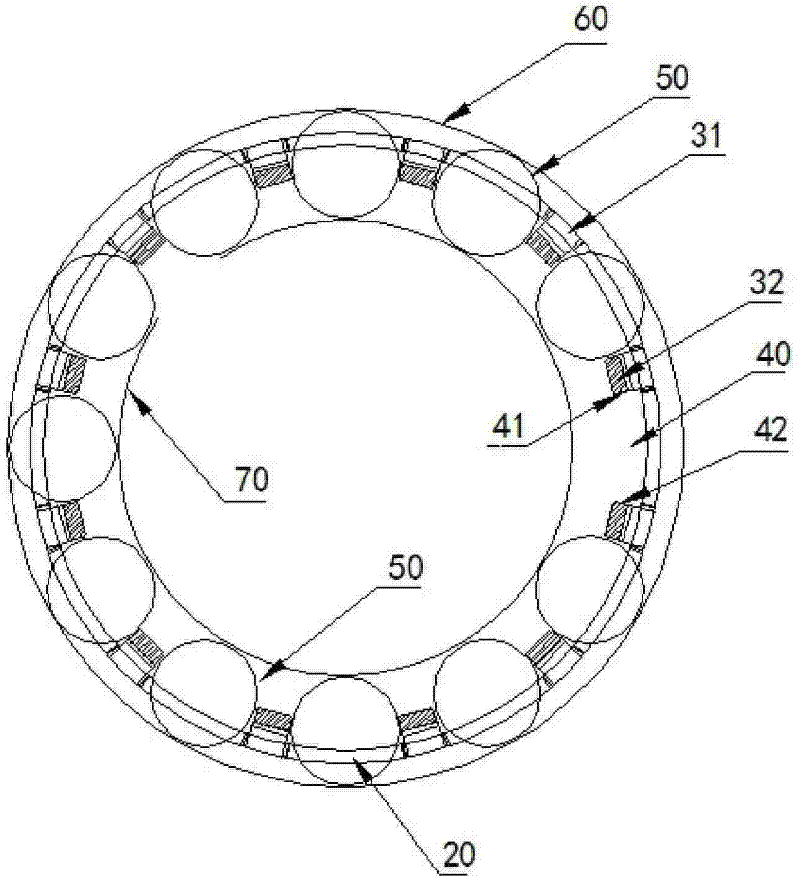

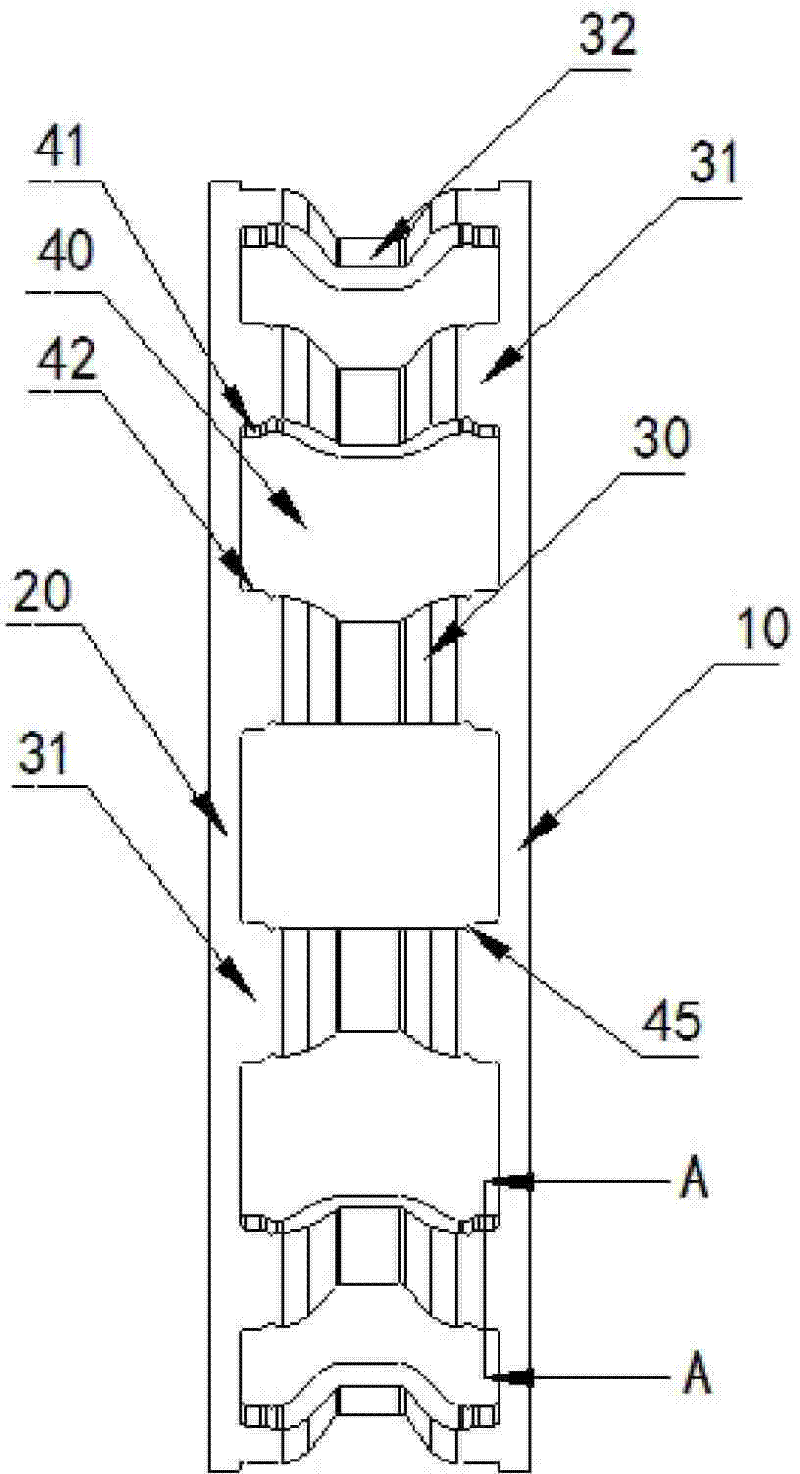

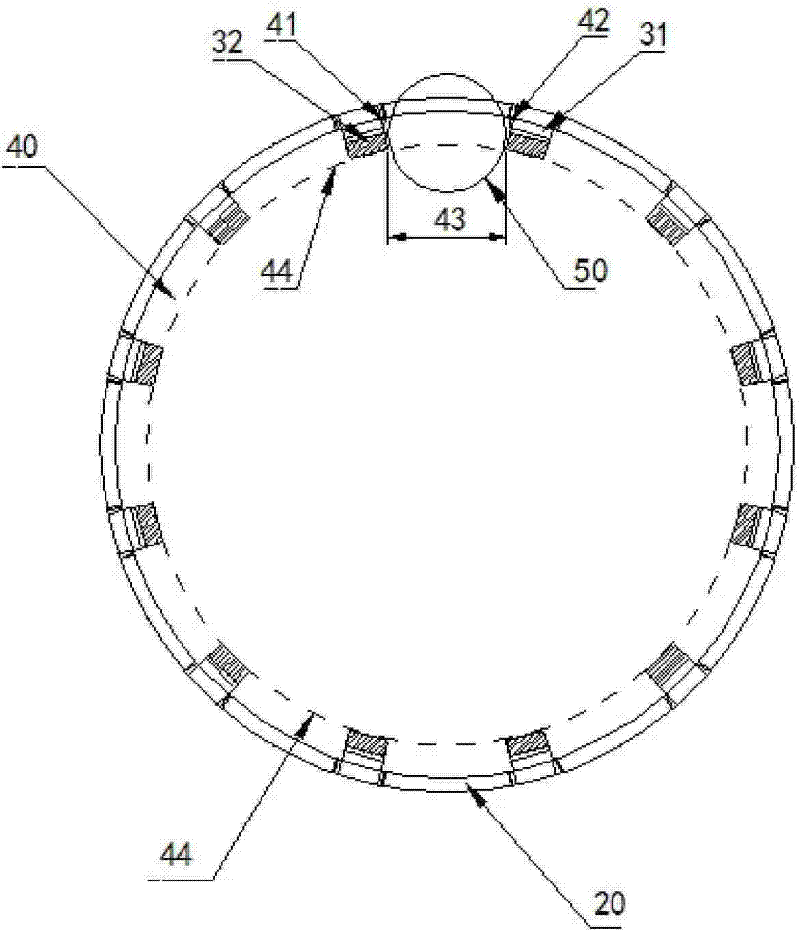

[0031] figure 1 In the shown embodiment, a processing technology of a bearing retainer is characterized in that it mainly includes the following steps

[0032] 1. Cutting: According to the bearing capacity required by the bearing to be processed, calculate the circumference length and height of the cage that needs to be processed to install the locking cylindrical roller, and punch the used low carbon steel plate material according to the calculated size. A long block that meets the circumference length and height of the stamping retainer;

[0033] 2. Punch out all the pockets at one time: according to the size of the bearing cylindrical rollers to be installed and used, use a stamping die to punch out all the pockets that need to lock the cylindrical rollers at one time by punching out the long strips that have been punched out , including the punched pocket surface structure and its oblique slope structure, the punched pocket is symmetrically provided with a slope that expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com