Simulation fracture plugging test device and test method

A technology for simulating fractures and test equipment, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., and can solve the problem of unreasonable location and structure of leakage beds and fracture plates, and fractures that cannot truly simulate leakage formations and other problems, to achieve the effect of convenient operation, ingenious and reasonable structure, and prevention of serious leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

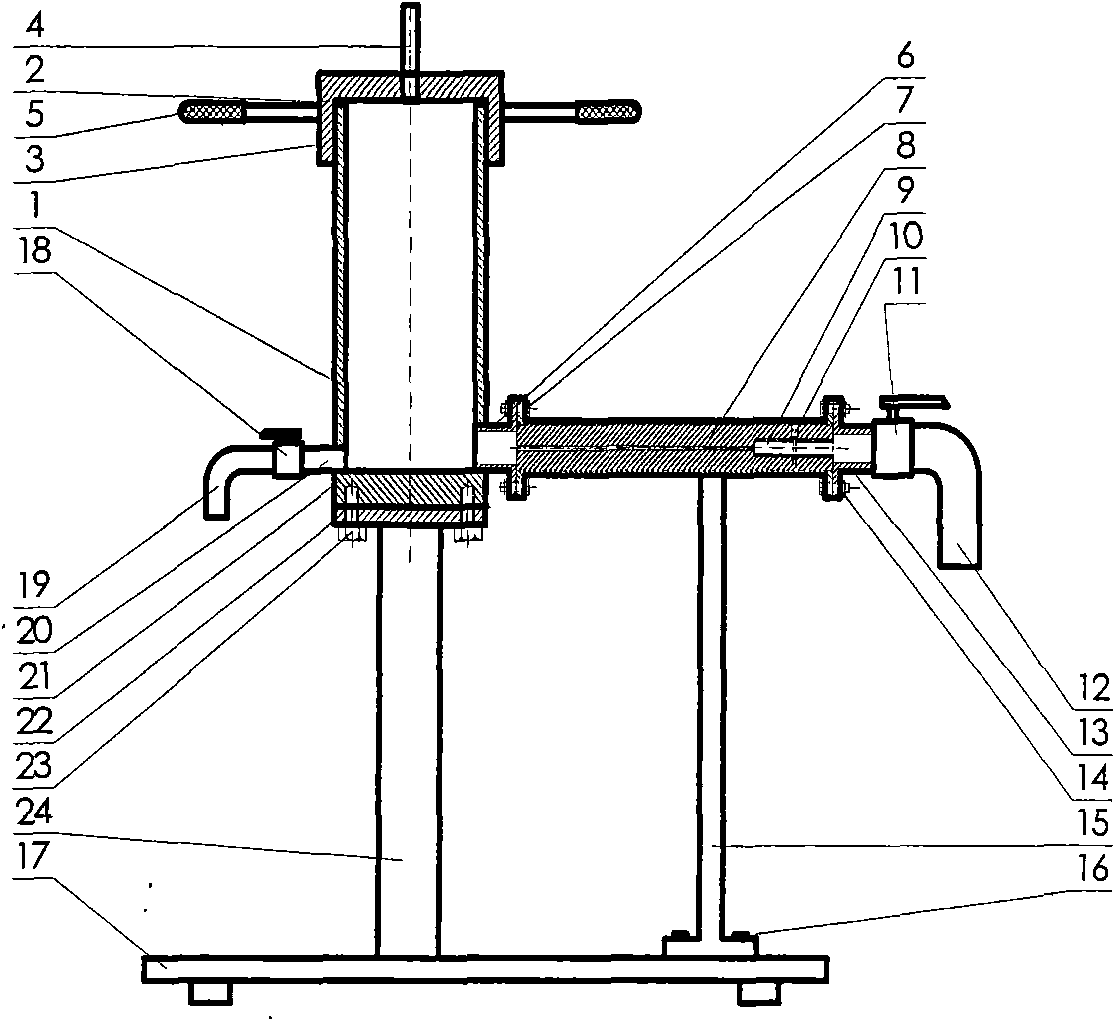

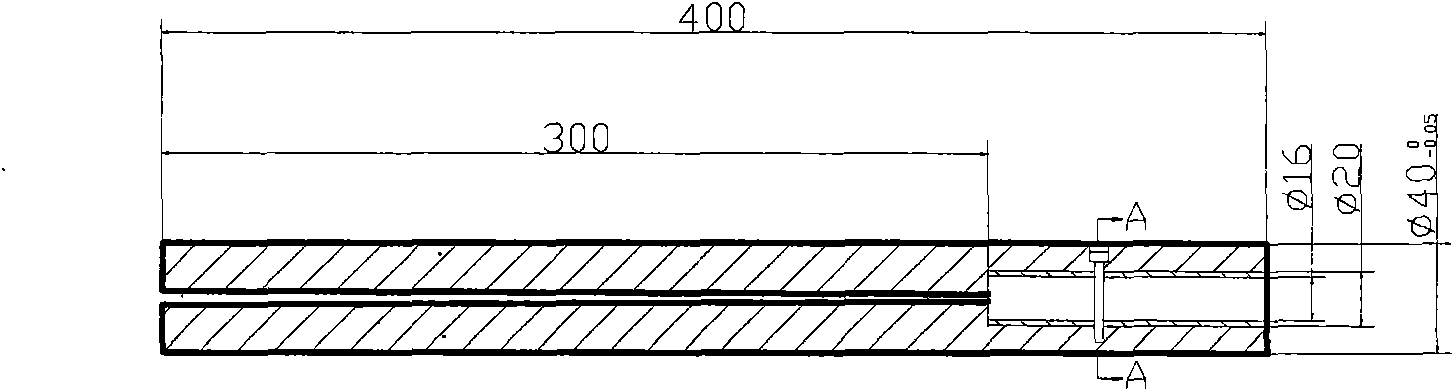

[0013] During the experiment, put the plugging liquid required for the test into the high-pressure container 1, rotate the upper cover 3 of the container clockwise, and seal it with the high-pressure container ○-shaped sealing ring 2 placed on the upper end of the high-pressure container 1, and install a needle on the top of the upper cover. Type stop valve 4 is connected with the quick joint of the high-pressure gas pipe of the nitrogen cylinder. According to the needs, select a constant pressure difference to simulate the field conditions or increase or decrease the pressure at a certain rate, so that the plugging liquid is injected into the channel flange 6 under pressure. Simulate the fracture test module 8 in the wellbore 7. The test module is positioned by the module positioning sleeve 9 and fixed by the module connection fastening screw 10. When the plugging fluid passes through the fracture and compresses the plugging fluid outlet control valve 11, it flows out along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com