Steam washing machine with hanging-type clothes hanger

A washing machine and hanger technology, applied in the field of washing machines and steam washing machines, can solve the problems of unsatisfactory washing effect, water consumption of pulsator type washing machine, and unclean clothes of drum type washing machine, and achieve good washing effect, soft washing, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

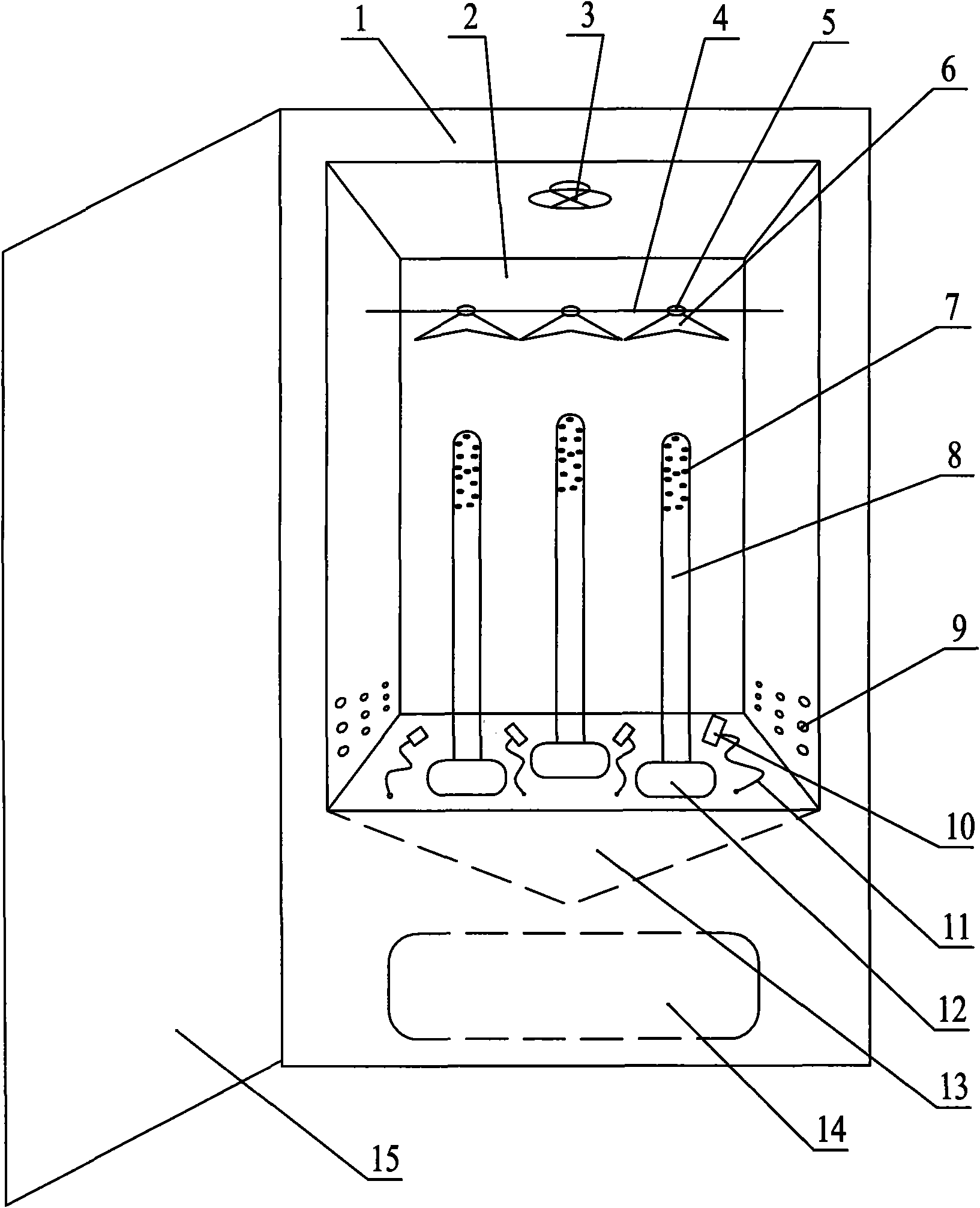

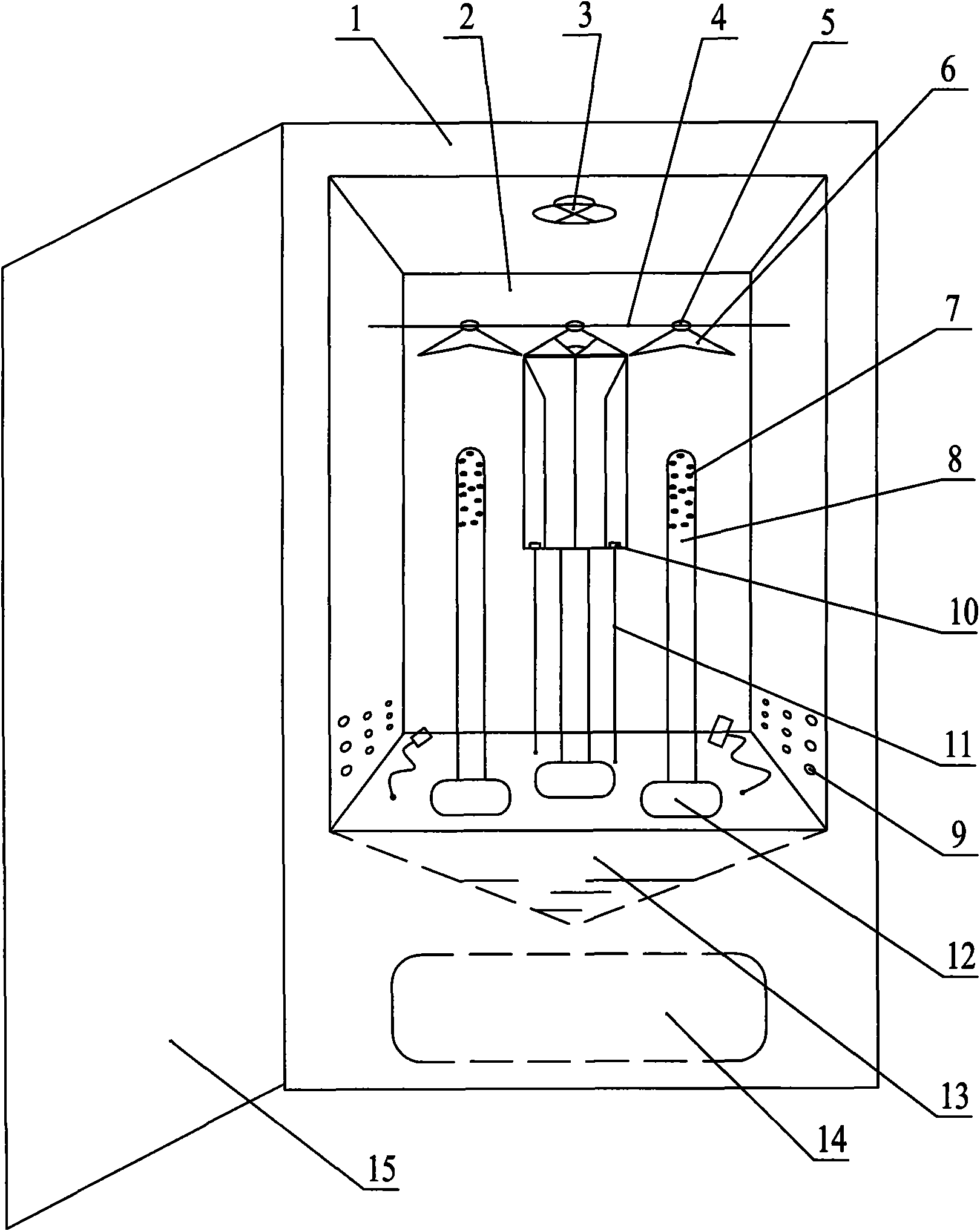

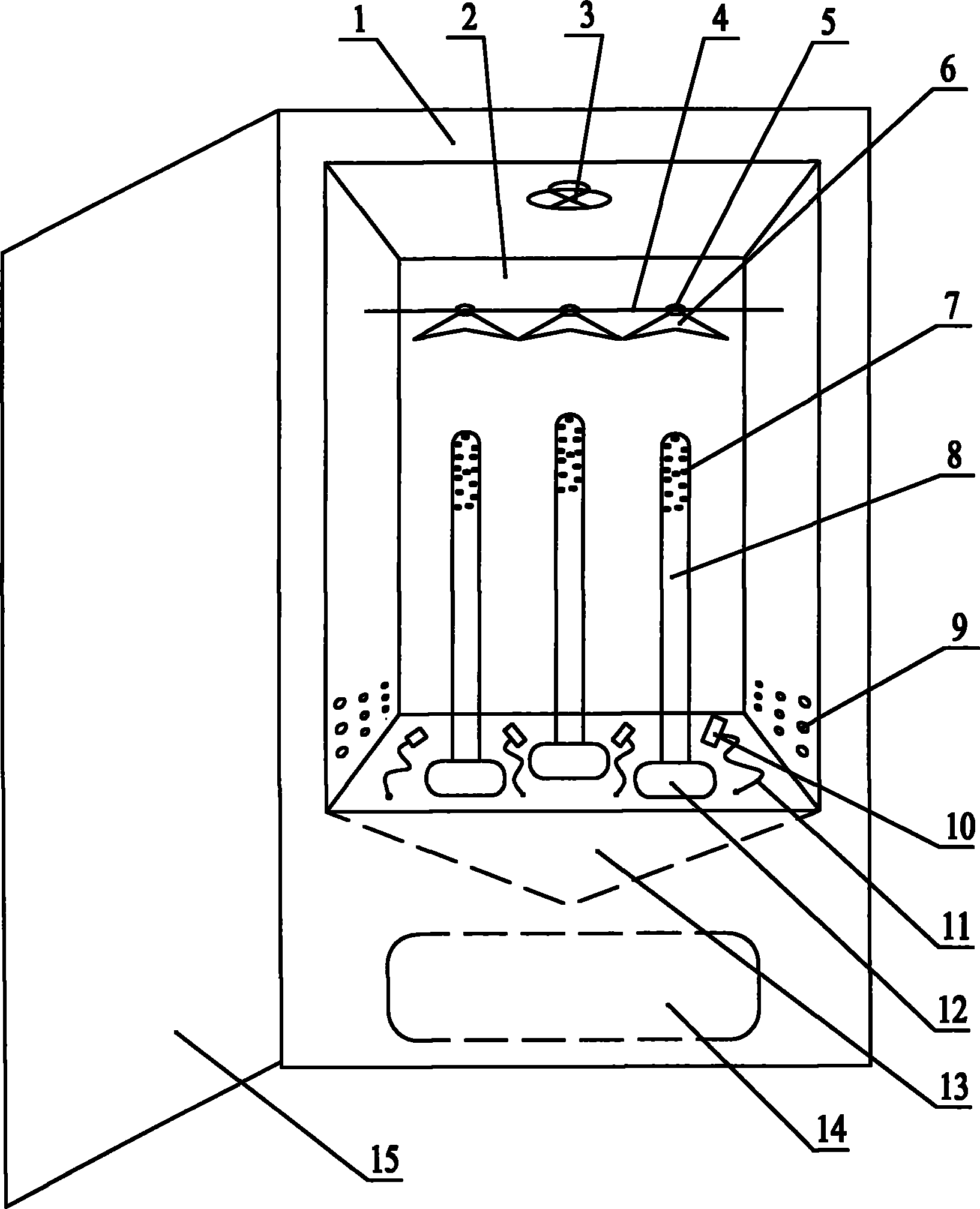

[0022] As shown in the figure: the steam washing machine in the embodiment includes a box body 1 equipped with a side-opening sliding door 15 . A steam generator 14 is installed in the bottom of the casing 1, and the steam generator 14 adopts a commercially available product. A cleaning chamber 2 for accommodating clothes is provided in the casing 1, and an outer air injection hole 9 is provided on the wall of the cleaning chamber 2, and the outer air injection hole 9 communicates with the steam generator 14 for spraying into the casing 1. into the steam; the upper part of the cleaning room 2 is provided with a hanging rod 4, and three hangers 6 are installed on the hanging rod 4; three internal hollow air jets 8 are vertically installed at the bottom of the cleaning room 2, and the air jets 8 are arranged on the hanging Right below the clothes hanger 6 and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com