No-fan flame multilayer oxygen supply energy saving burner

A technology without fans and burners, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient combustion of gas, taken away immediately after use, and no combustion of gas, and achieve smooth drainage and windproof performance. Excellent, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

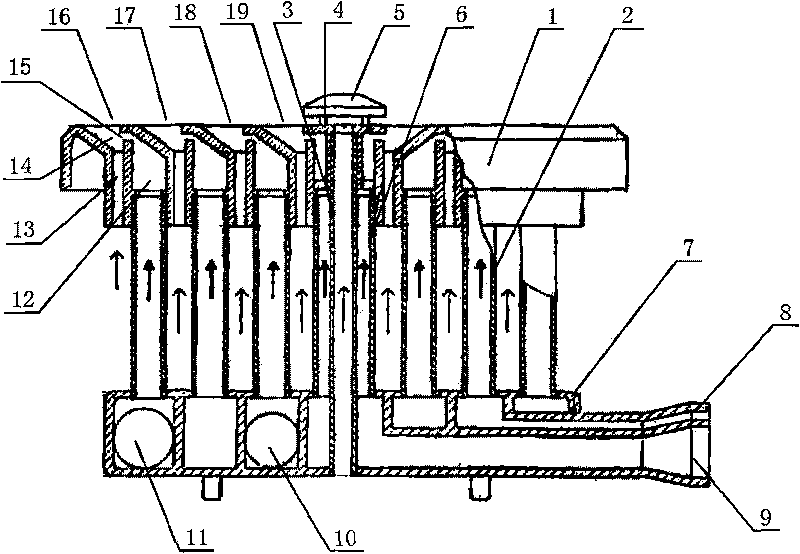

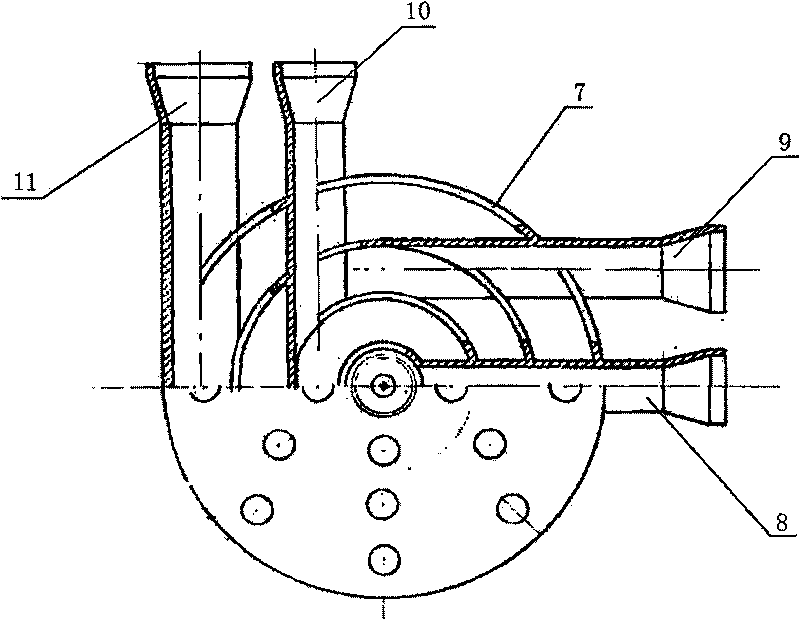

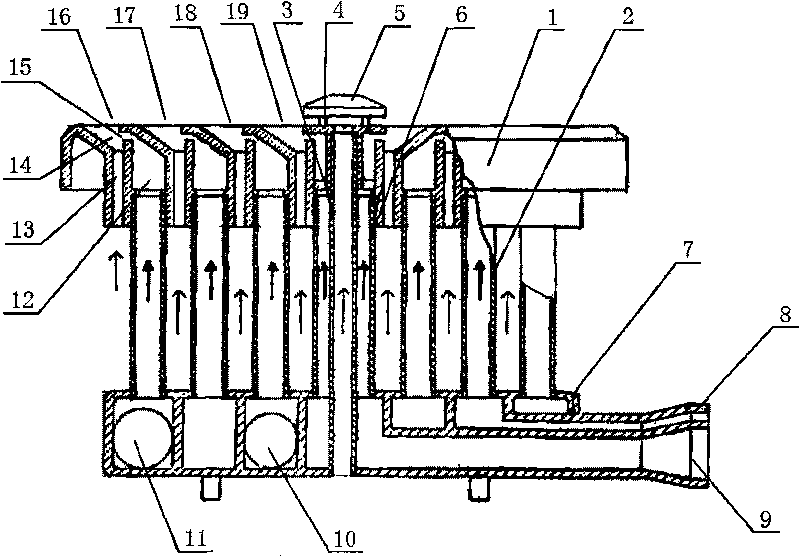

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0018] Such as figure 1 , figure 2 As shown, the present invention is mainly composed of a combustion disk 1, a gas pipe 2, an oxygen supply pipe 3, a top cover 5, an intake sleeve 6 and a flow divider 7; the upper part of the combustion disk 1 is sequentially provided with a central combustion chamber 19 from the center 1, the first stage outer combustion chamber 18, the second stage outer combustion chamber 17 and the third stage outer combustion chamber 16, the lower part of the burning disc 1 is provided with the central combustion chamber 19, the first stage outer combustion chamber 18, the second stage outer combustion chamber respectively Combustion chamber 17 and the connection hole that the third stage outer combustion chamber 16 communicates correspondingly; On the diverter 7, be provided with central air intake hole, first stage outer air inlet hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com