Construction method of temperature decrease and crack prevention of mass concrete by utilizing thin-walled corrugated pipe circulating water system

A technology of circulating water system and construction method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problem that the cooling effect of large-volume concrete is not significant, the handling and connection are labor-intensive and time-consuming, and the quality of joints cannot be obtained. Guarantee and other issues, to achieve the effect of significant cooling and anti-cracking effect, complicated operation, simple and easy operation of blanking

Inactive Publication Date: 2011-01-05

中国建筑第五工程局有限公司东莞分公司

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this method is that the amount of steel pipes is large, so its handling and connection are labor-intensive and time-consuming. Elbows and joints are used to connect the steel pipes at the corners and lengths. Elbows and joints are threaded, and the material needs to be cut and the operation is complicated; the steel pipe connection can also be connected by welding, which requires a large amount of welding, labor and electricity, the quality of the joints cannot be guaranteed, and the construction time is longer , the construction cost is high, and the thermal conductivity of steel pipes is average, resulting in the insignificant effect of cooling and cracking resistance of large-volume concrete, which greatly restricts the large-scale popularization and application of cooling and cracking resistance of large-volume concrete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

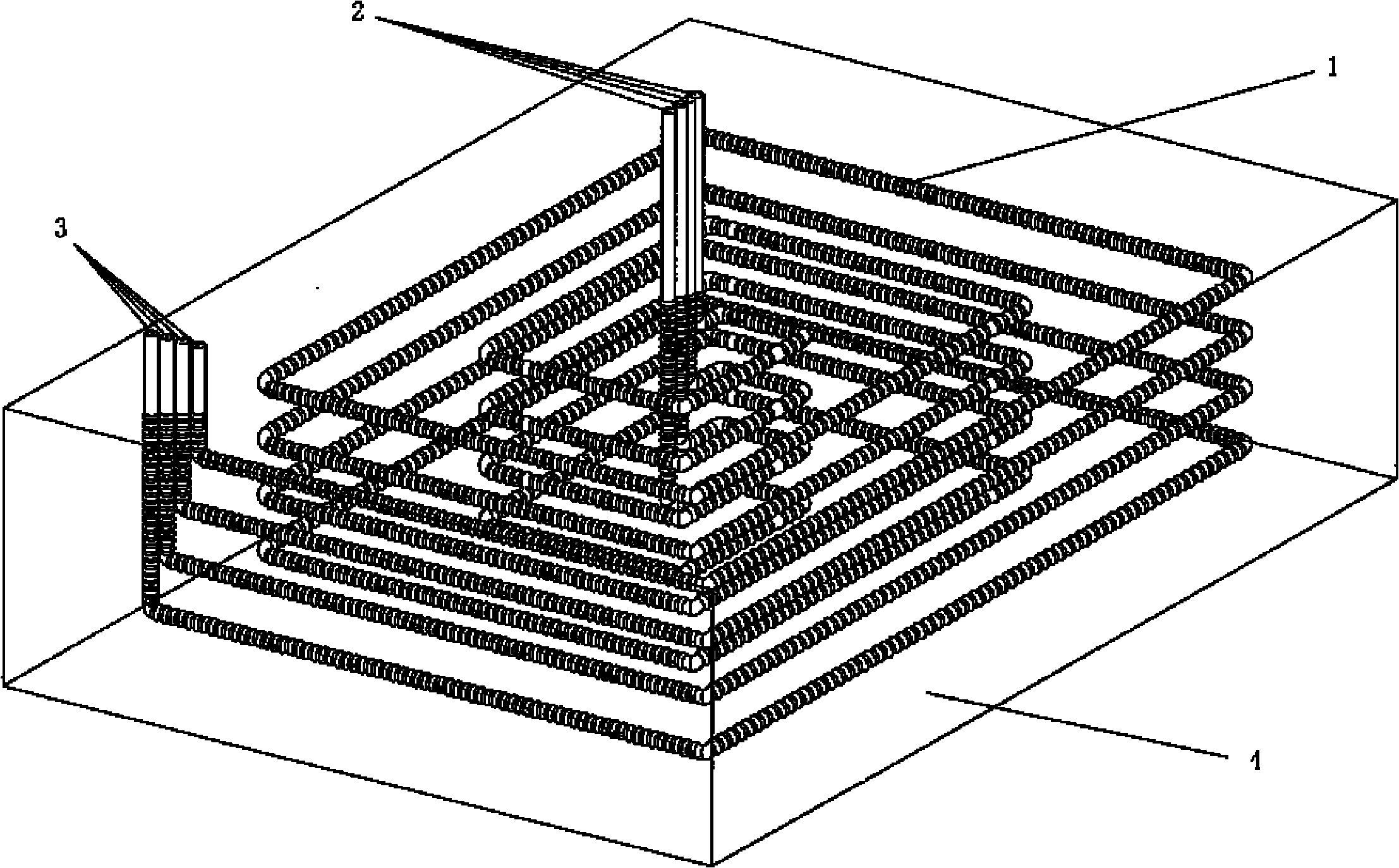

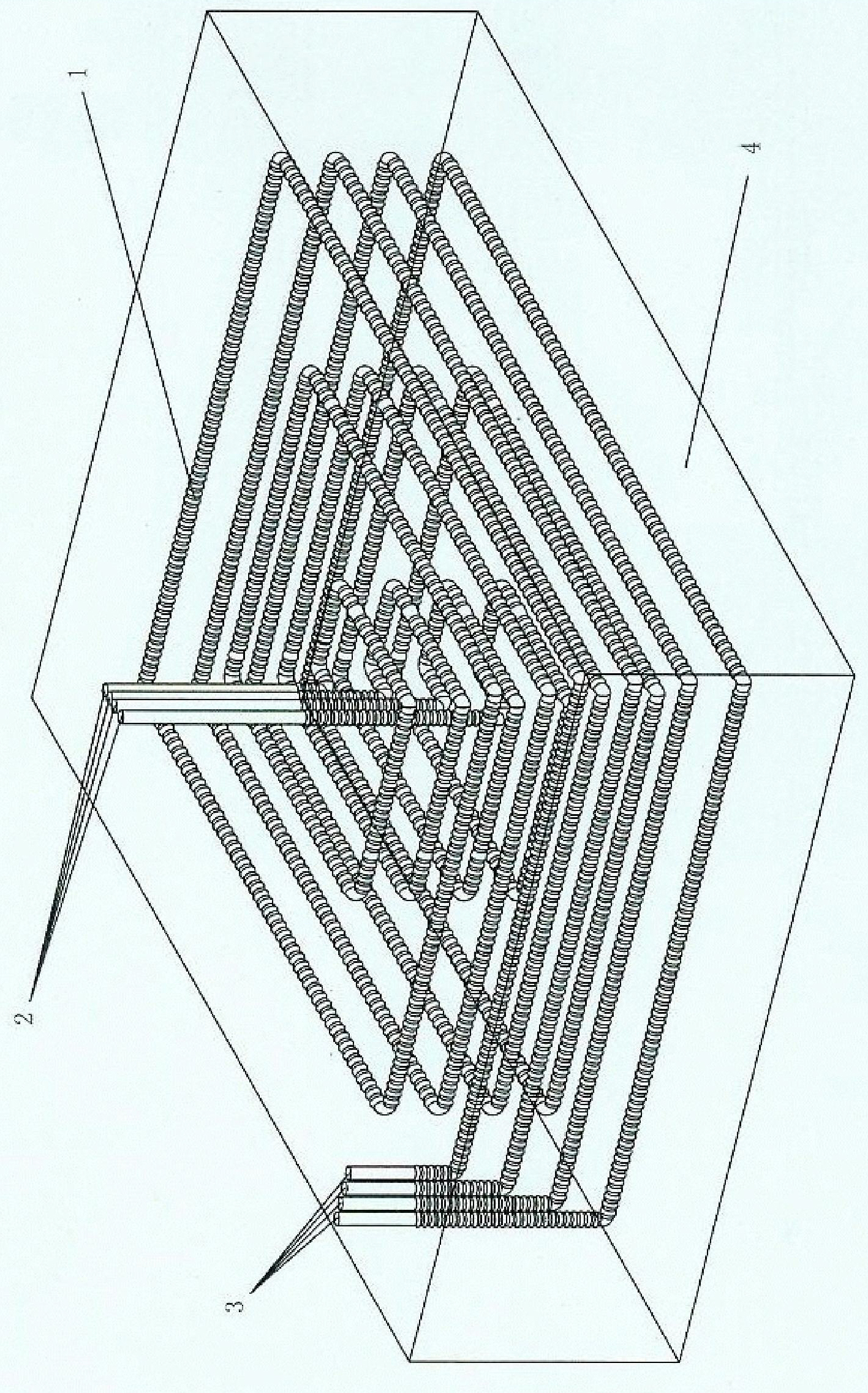

The invention relates to a construction method of mass concrete temperature decrease and crack prevention by utilizing a thin-walled corrugated pipe circulating water system, which comprises the following steps: (1) selecting circulating water pipes: selecting thin-walled iron-sheet corrugated pipes as the pipeline materials for arranging circulating water pipes; (2) arranging a circulating waterpipe system: in the process of binding a reinforcing cage, installing and fixing the corrugated pipes to the reinforcing cage in a spiral or laminated way according to the structure form of a mass concrete, wherein, the distance between layers is from 500 mm to 2000 mm, the distance between rows in the layers is also from 500 mm to 2000 mm, and providing a water inlet pipe and a water outlet piperespectively connected with the corrugated pipes on the upper part of the mass concrete; (3) arranging temperature measuring points; (4) pouring the concrete; and (5) keeping maintenance. The construction method has the advantages of obvious effect on the temperature decrease and crack prevention of the mass concrete, low cost, simple operation, convenient and quick construction and convenience in the connection of the corrugated pipes.

Description

Construction method of cooling and anti-cracking large-volume concrete using thin-wall corrugated pipe circulating water system technical field The invention relates to the field of building engineering construction, in particular to a construction method using a thin-walled corrugated pipe circulating water system for cooling and cracking of large-volume concrete. Background technique Mass concrete construction is very common in modern construction projects, and the construction technology for cooling and cracking of mass concrete is more and more commonly used in construction sites. However, how to effectively cool down and resist cracking of large-volume concrete, ensure construction quality, reduce construction difficulty, and reduce construction cost has become a practical problem that needs to be solved urgently. In order to effectively control the surface cracks and through-cracks of mass concrete caused by temperature stress, the temperature shrinkage stress is us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04G21/02

Inventor 王国保夏斌王晓冬施旭光彭双阳周怀春叶文杰

Owner 中国建筑第五工程局有限公司东莞分公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com