Automatic high speed lancing device by layered conveying

An automatic, slitting technology, applied in the direction of transportation and packaging, packaging, rigid/semi-rigid container manufacturing, etc., can solve problems such as inability to achieve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

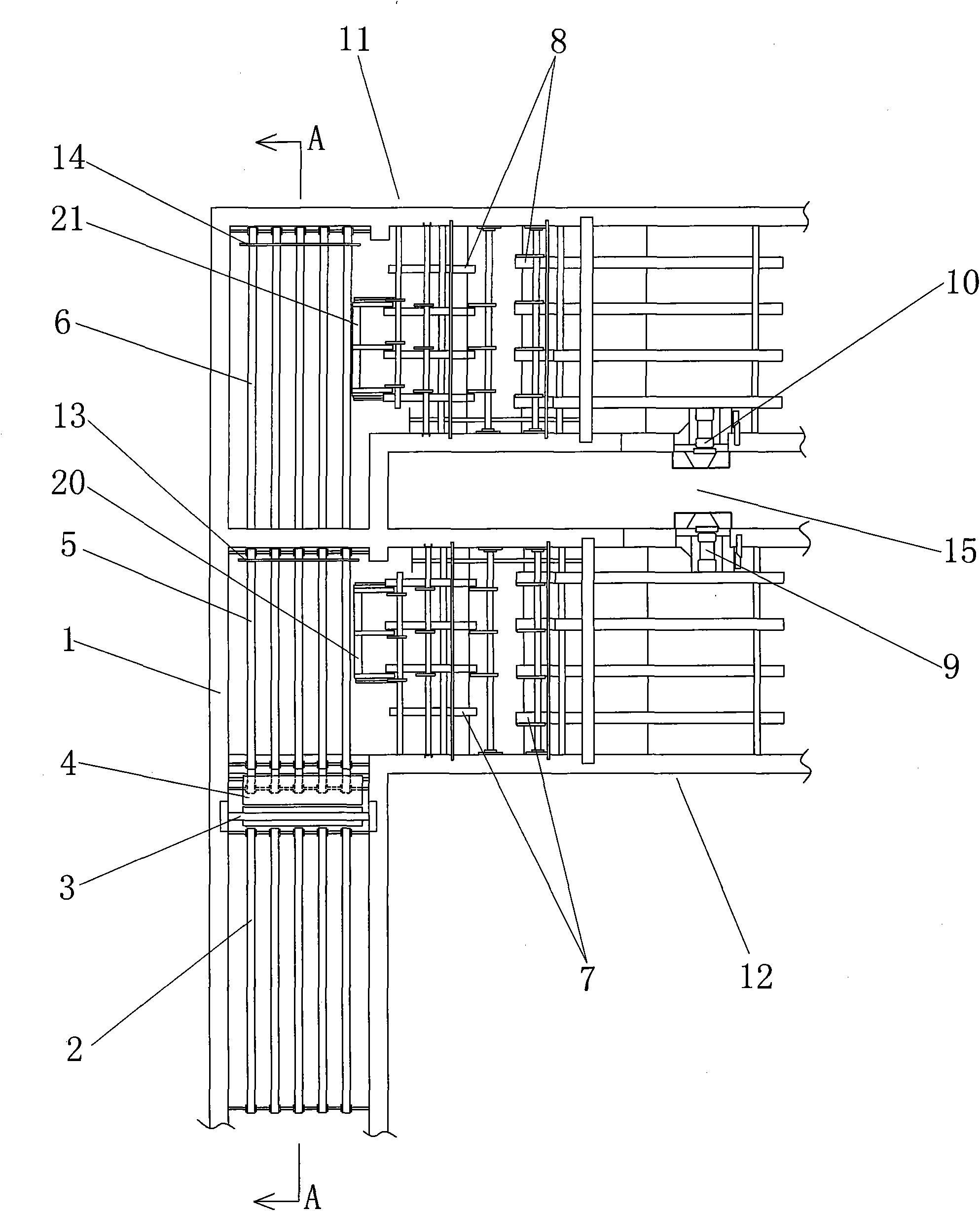

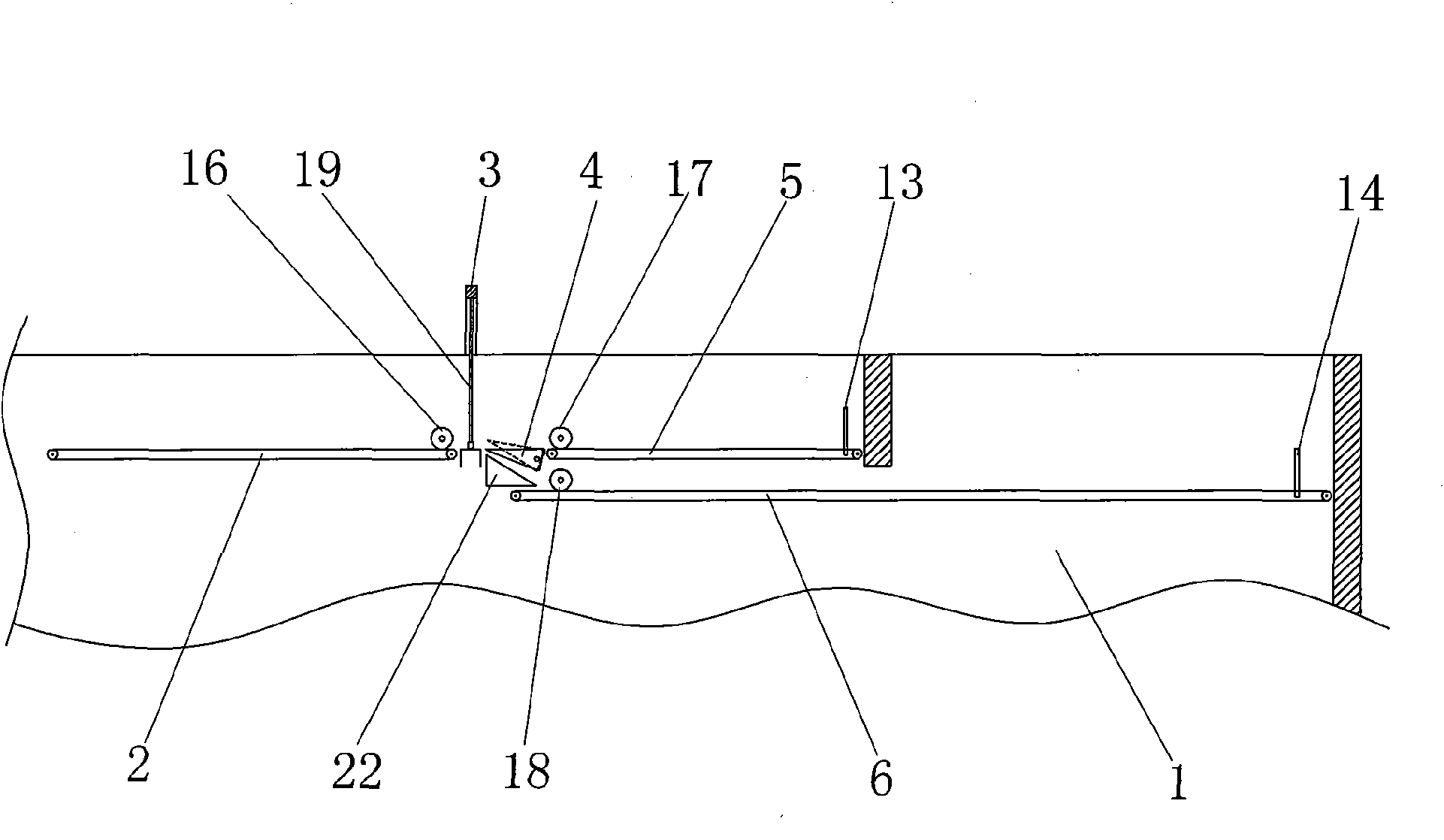

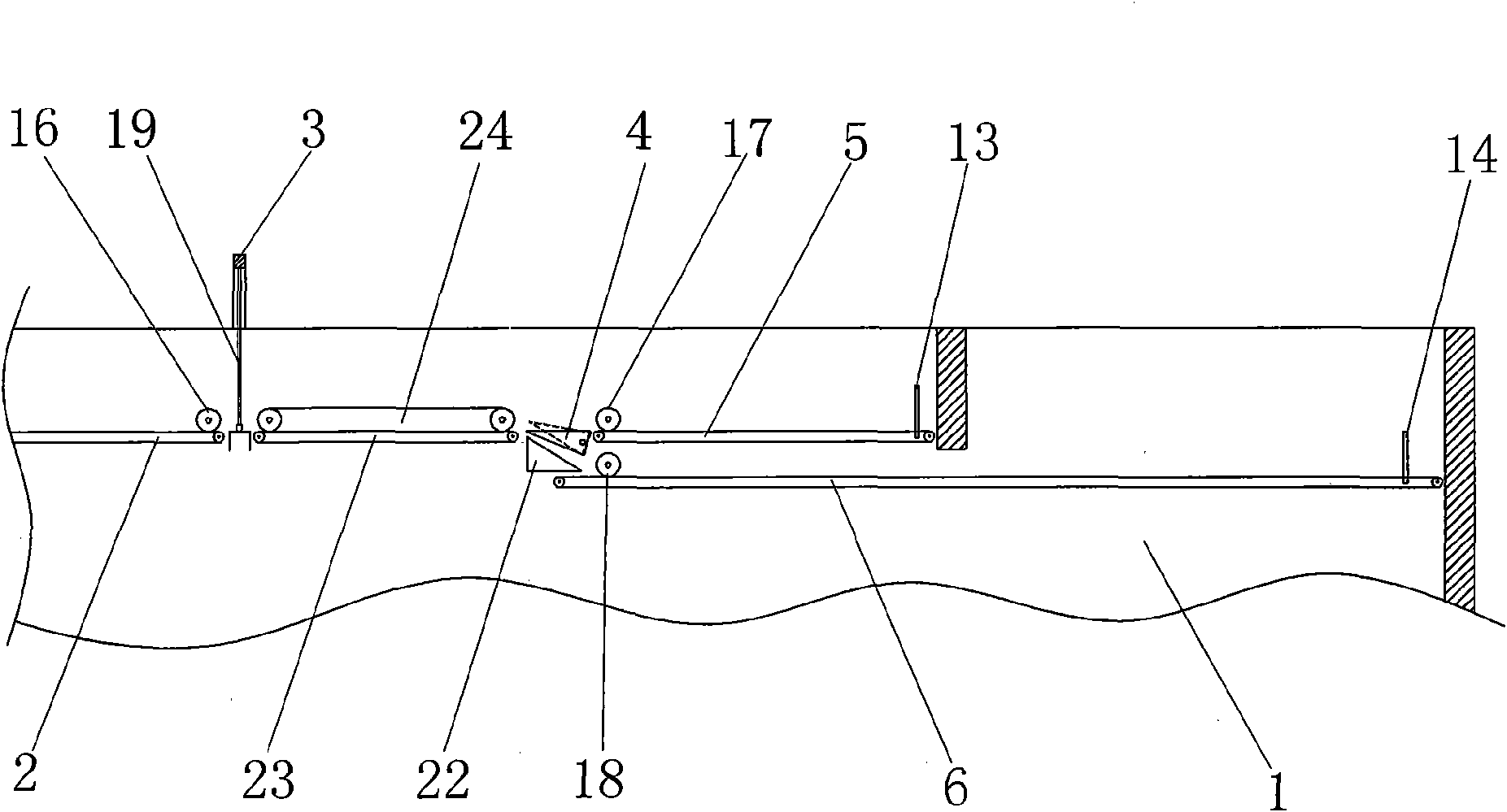

[0025] refer to Figure 1 ~ Figure 2 , the automatic high-speed slitting device for layered conveying is characterized in that it includes a frame 1 and a roll bag material longitudinal conveying mechanism 2 installed thereon, a cutting mechanism 3, a swing diverter 4, a rear longitudinal conveying mechanism 5 and 6. Transverse conveying mechanisms 7 and 8, automatic sewing machines 9 and 10, wherein the roll bag material longitudinal conveying mechanism 2, cutting mechanism 3 and swing diverter 4 are each one, rear longitudinal conveying mechanisms 5 and 6, transverse conveying mechanisms 7 and 8. There are two automatic sewing machines 9 and 10 respectively. The rear longitudinal conveying mechanism 5, the horizontal conveying mechanism 7 and the automatic sewing machine 9 form an independent sewing operation mechanism 11, and the rear longitudinal conveying mechanism 6, the transverse conveying mechanism 8 and the automatic sewing machine 10 constitute Another independent s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com