Method for improving shape accuracy and processing efficiency of off-axis aspheric mirror

An off-axis aspheric surface and processing efficiency technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of difficult to process off-axis aspheric mirrors, etc., and achieve the effects of easy separation, high processing efficiency and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

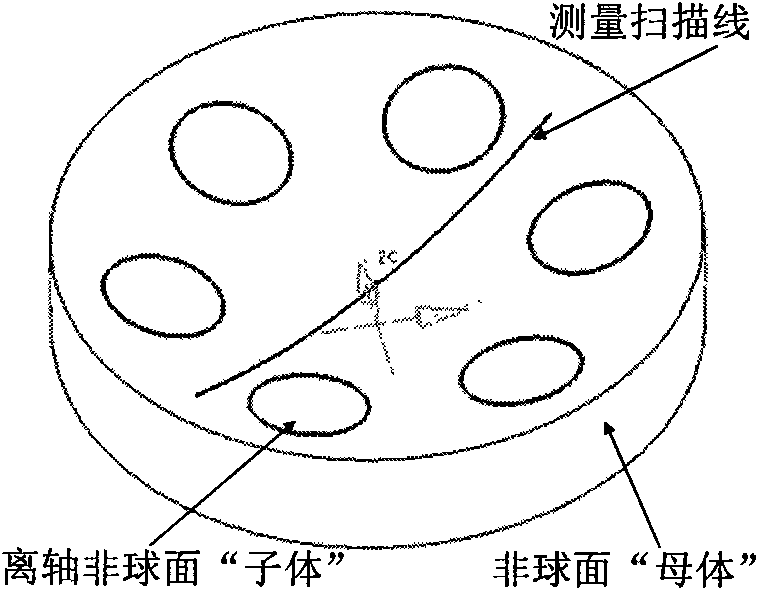

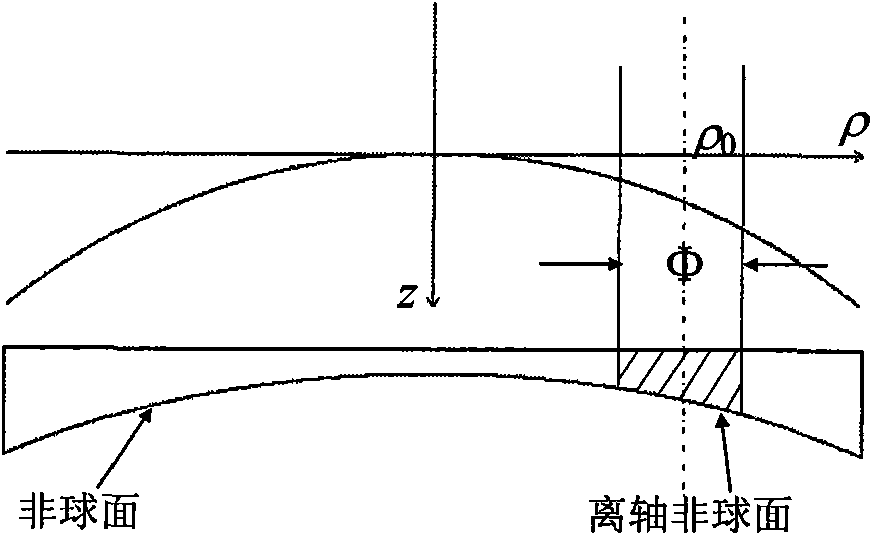

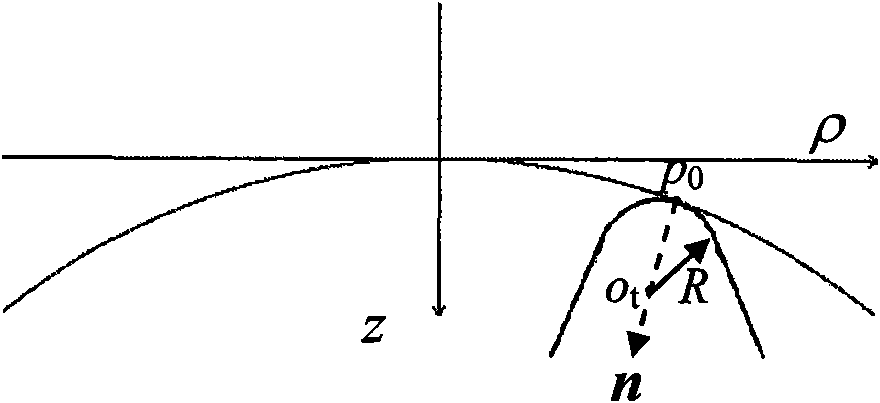

[0018] Because the off-axis aspheric mirror is a part of the aspheric surface, for the off-axis aspheric surface with small size or small Sag, the ultra-precision machining of the off-axis aspheric surface can be completed by processing the whole aspheric surface. parent body" processing method. figure 1 is a schematic diagram of processing. In this method, the entire aspheric surface is the processing "parent body", and n through holes are evenly distributed on it, and the off-axis aspheric surface "sub-body" to be processed is placed in the opening part, and the aspheric surface parent body They form a complete aspheric surface together, and perform ultra-precision turning processing at the same time, and process multiple off-axis aspheric surfaces at one time. There is an appropriate amount of space between adjacent holes, which is used for ultra-precision measurement during the compensation process, and realizes the control of the overall compensation machining allowance. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com