Image sensor and manufacturing method thereof

A photodetector and color filter array technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., to achieve the effects of improving sensitivity, reducing noise, and reducing interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

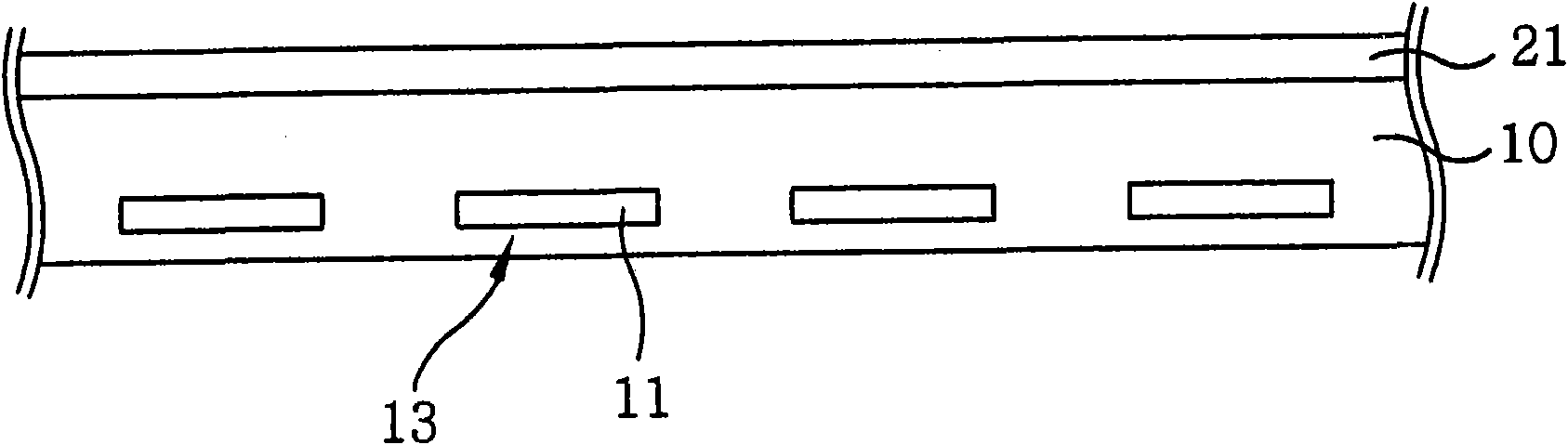

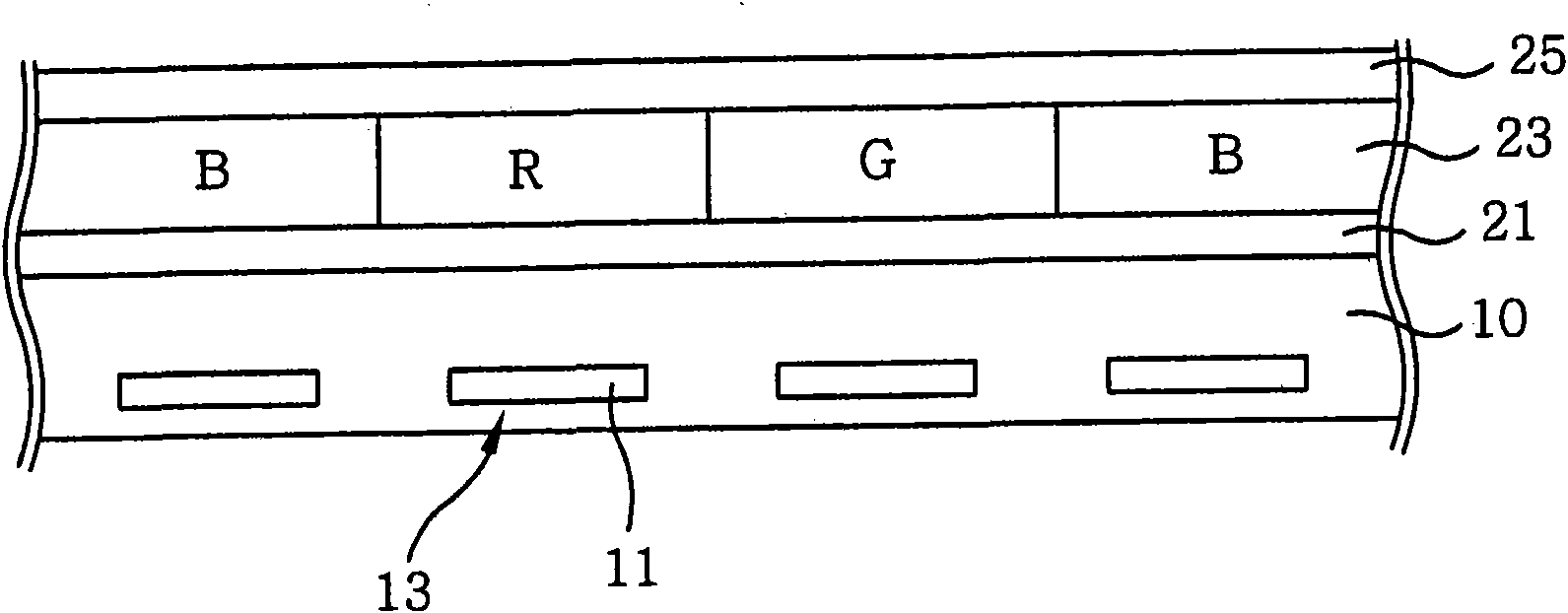

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings that form a part of this application.

[0024] figure 2 is a cross-sectional view of an image sensor formed by using an image sensor manufacturing method according to an embodiment of the present invention. refer to figure 2 , the image sensor of the embodiment of the present invention may include: a semiconductor substrate 100 having a photodetector 104 and a color filter array 108; a planarization layer 110 having a stepped portion, wherein the stepped portion corresponds to a first group of micro The area of the lens 112 and the area where the second set of microlenses 116 may be formed; the first set of microlenses 112 and the second set of microlenses 116 . The first set of microlenses 112 has a hydrophilic surface characteristic, while the second set of microlenses 116 has a hydrophobic surface characteristic. In addition, reference numeral 102 denotes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com