Test device of performance test of stepped diffuser of headbox

A technique of step diffusion, test device, applied in the field of paper machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

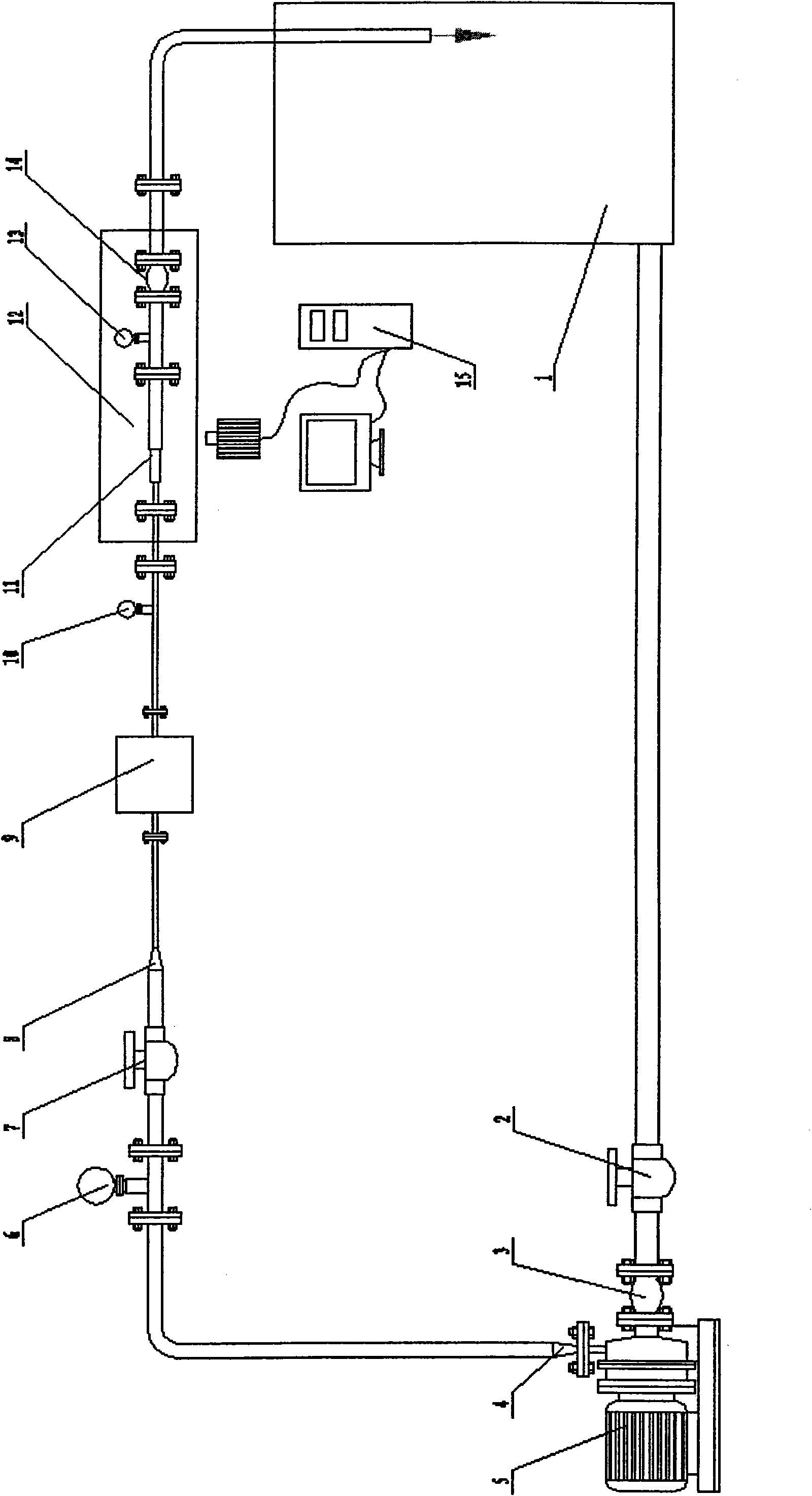

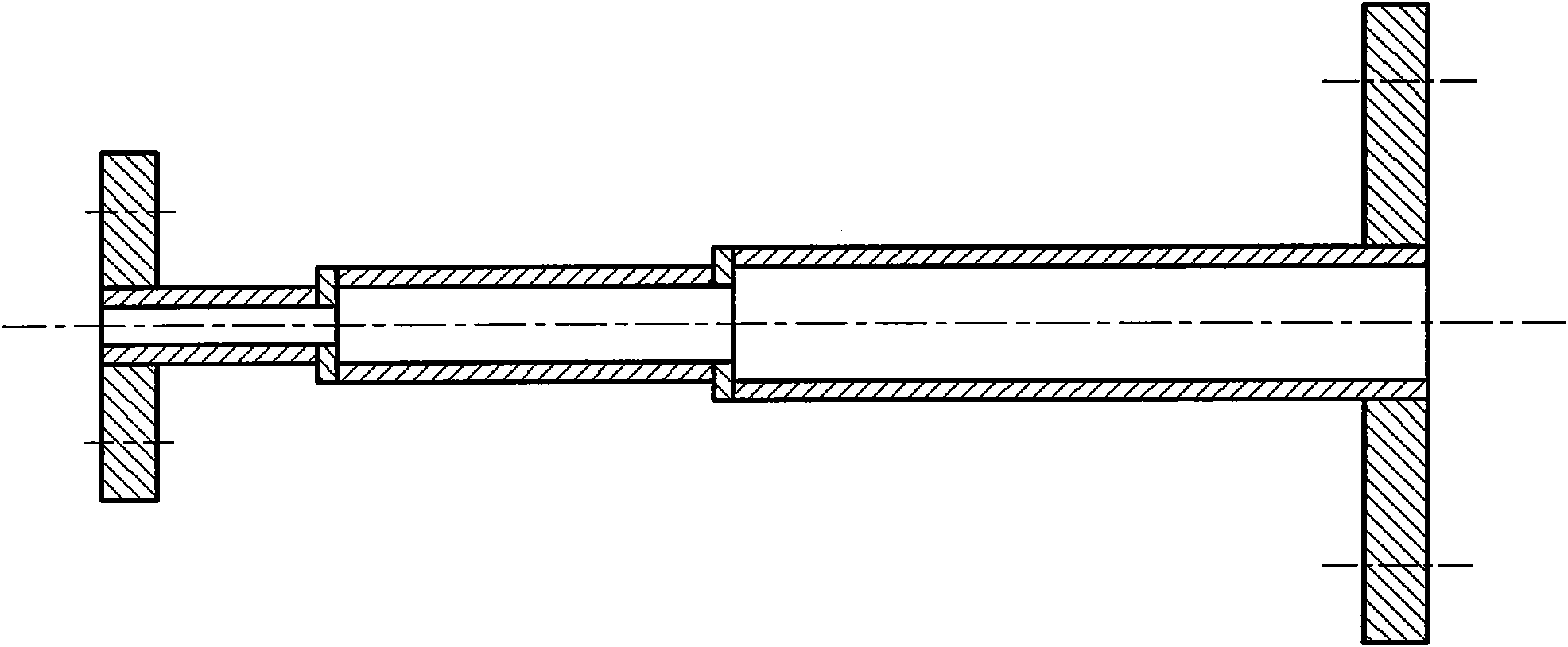

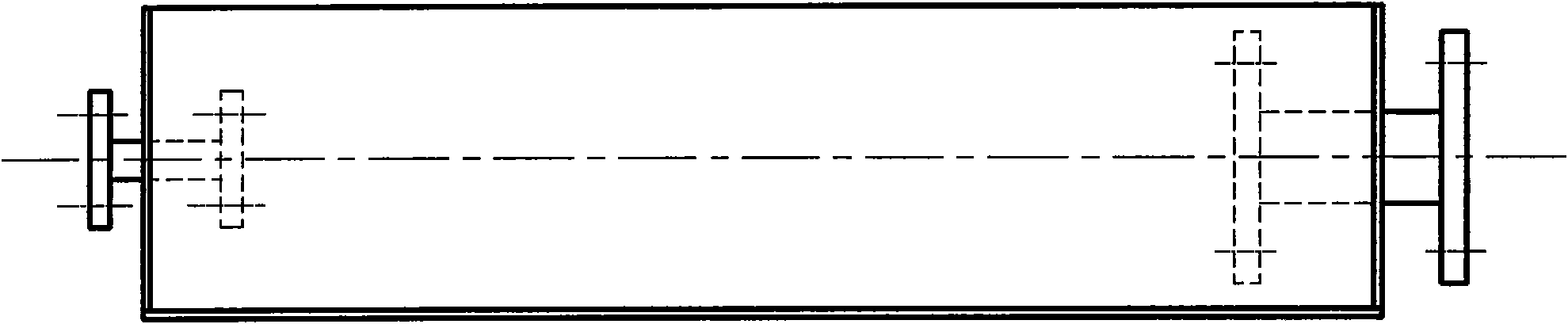

[0013] Such as figure 1 As shown, the test device for the performance test of the step diffuser of the headbox includes a water storage tank 1, a first ball valve 2, a first flexible single-ball rubber joint 3, a variable diameter flange 4, a centrifugal pump 5, an electromagnetic flowmeter 6, a first Second ball valve 7, variable diameter joint 8, steady flow box 9, first pressure gauge 10, transparent step diffuser 11, transparent water tank 12, second pressure gauge 13, second flexible single-ball rubber joint 14, PIV test system 15. Water storage tank 1, first ball valve 2, first flexible single-ball rubber joint 3, centrifugal pump 5, variable diameter flange 4, electromagnetic flowmeter 6, second ball valve 7, variable diameter joint 8, steady flow box 9. The first pressure gauge 10, the transparent stepped diffuser 11, the second pressure gauge 13, and the second flexible single-sphere rubber joint 14 are connected in sequence, and the transparent stepped diffuser 11, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com