Coupling element for connecting actuator to valve

A technology for connecting components and actuators, which is applied in the direction of connecting components, engine components, valve operation/release devices, etc., and can solve problems such as complex manufacturing processes, low first-pass yield, and the impossibility of automatic assembly of actuator systems , to achieve the effect of simplifying the low-cost manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

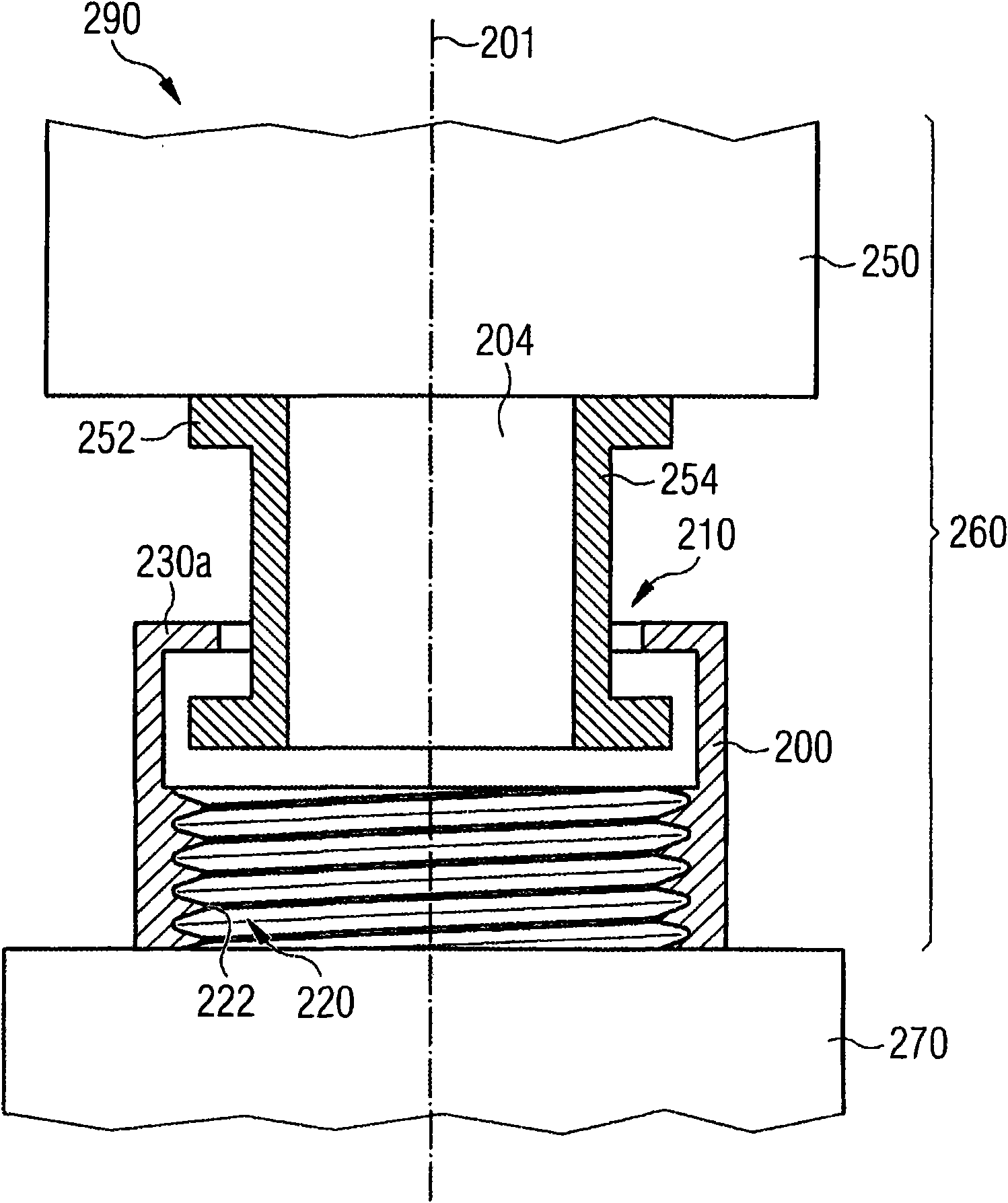

[0041] The Figure examples are schematic. It should be noted that similar or identical elements are provided with the same reference signs or with reference signs differing only by the first digit of the corresponding reference sign.

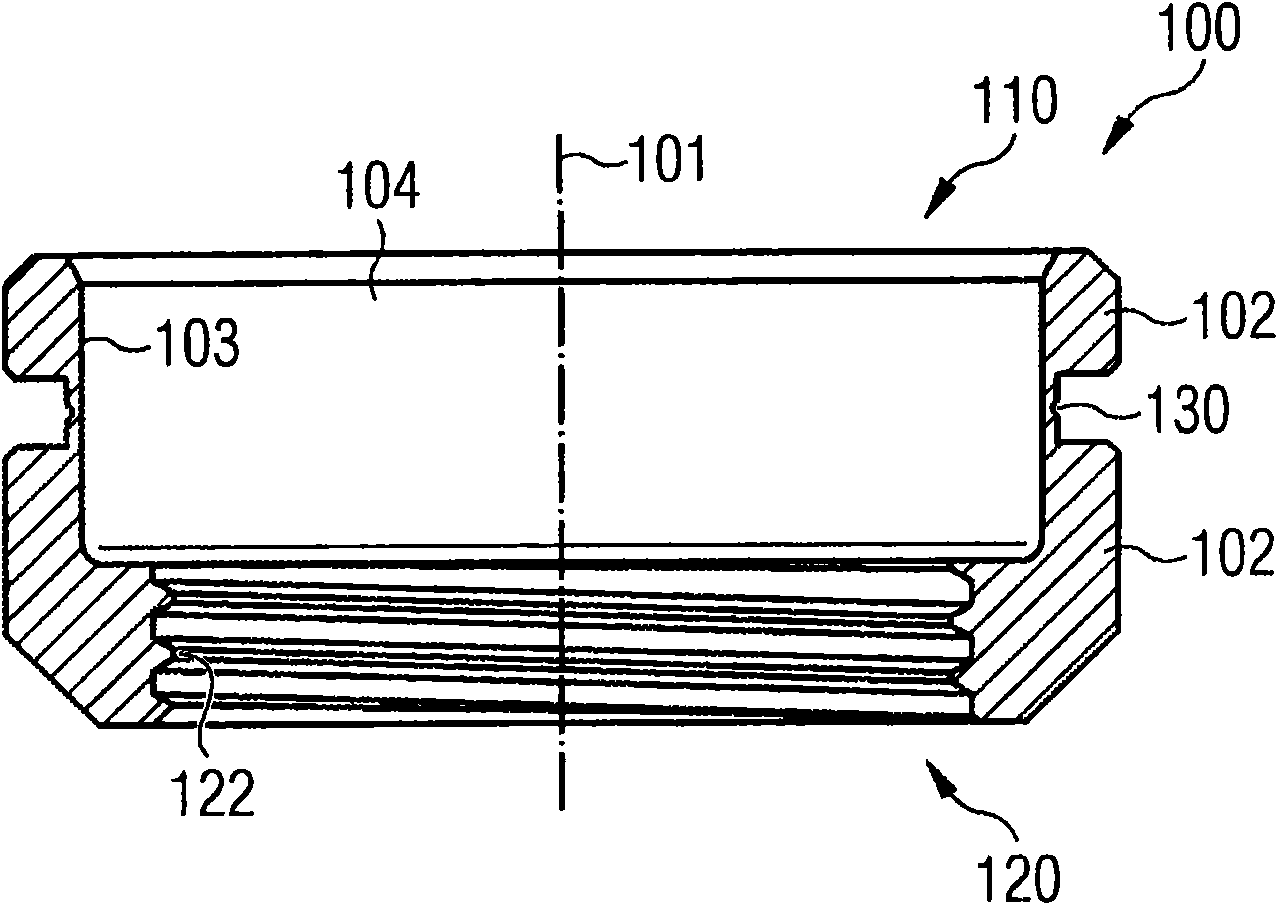

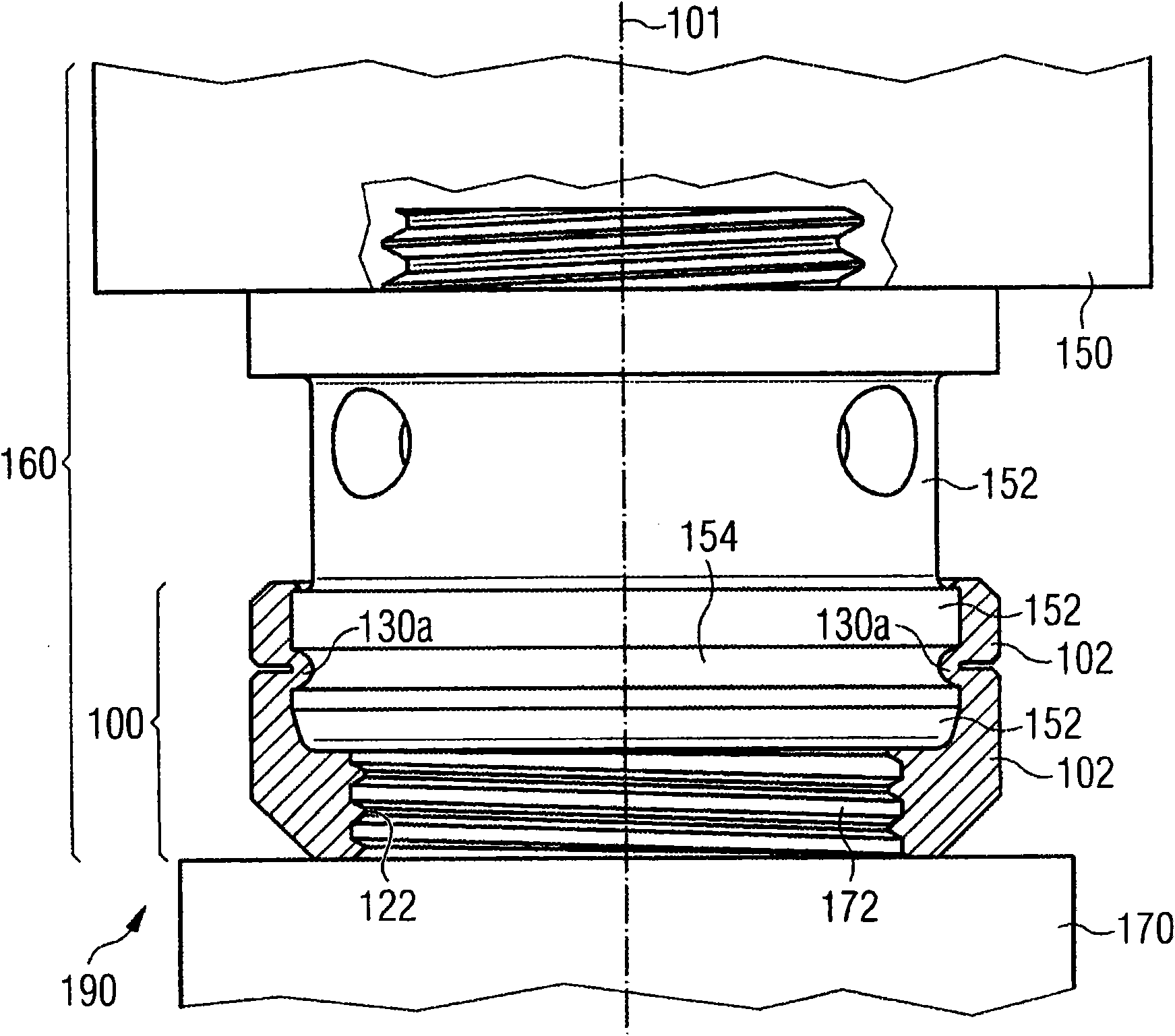

[0042] Figure 1a A connecting element 100 of a first embodiment of the invention is shown. Figure 1a The connection element 100 is shown in its initial state before being connected to the actuator.

[0043] According to the embodiment described herein, the connecting element is a nut 100 with an axis of symmetry 101 . The nut 100 includes a body 102 formed around an axis of symmetry 101 . A central opening 104 is formed in the body 102 . A side wall 103 substantially in the shape of a side surface of a cylinder, delimits a central opening 104 . The outer side of the nut 100 is hexagonal so that the nut 100 can be turned by means of, for example, a suitable open end wrench.

[0044] The nut 100 also has a first interface 110 . as will be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com