Method for refining isosorbide by distillation and melt crystallization coupling technology

A technology of isosorbide and melt crystallization, applied in the chemical field, can solve the problems of high production cost, poisonous, harmful to the health of production operators, etc., and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

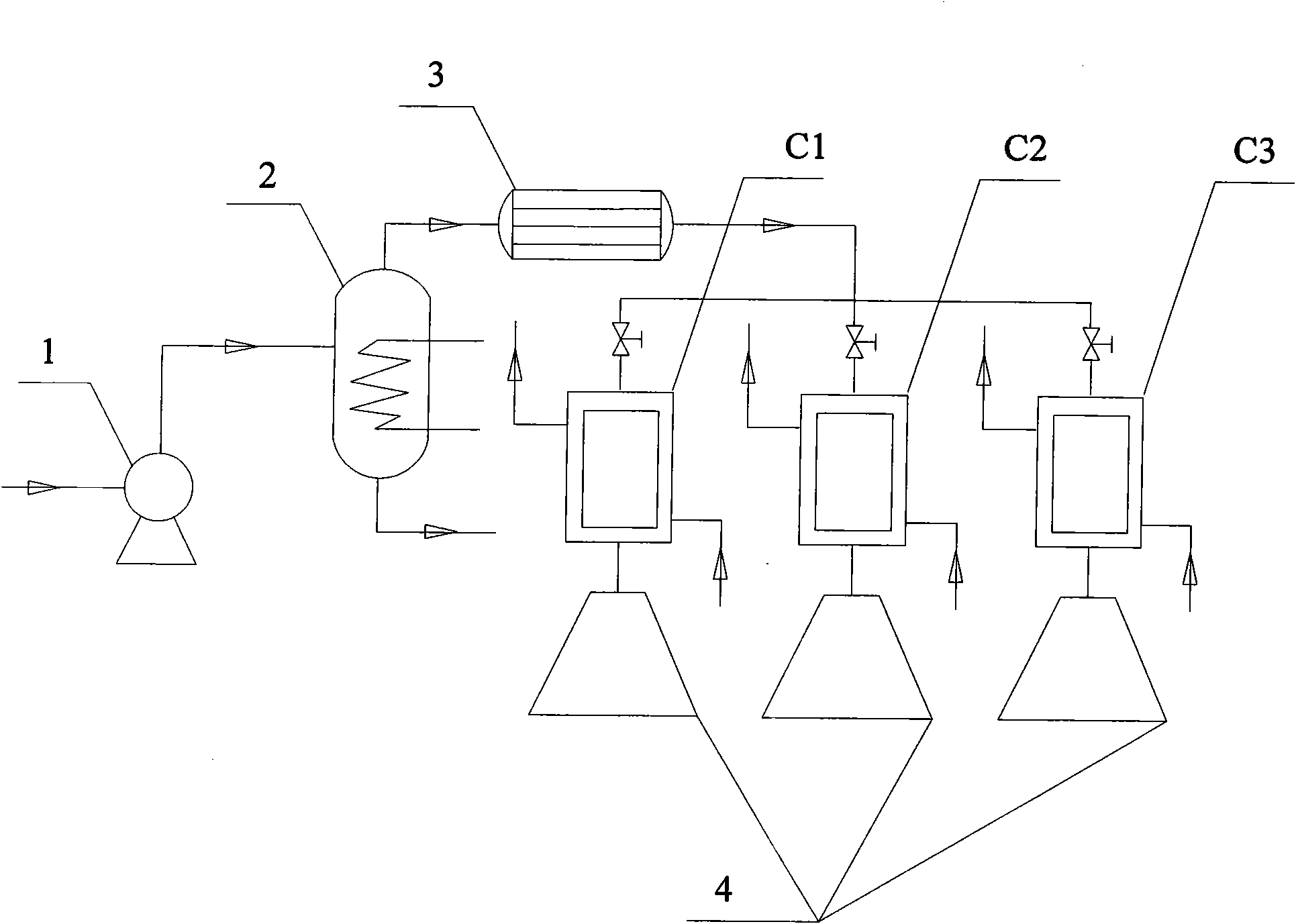

Image

Examples

Embodiment 1

[0019] 1Kg of sorbitol dehydration product was introduced into the distillation tank, and the content of isosorbide was detected to be 63%. The mixed solution was heated to 155° C., vacuumed, and the vacuum degree was controlled at 320 Pa to carry out vacuum distillation. The distilled low-boiling point fractions were collected and kept at 70°C, and then introduced into the crystallizer that had been filmed, and the crystal layer was grown for 0.8 hours, and then the temperature was lowered at a rate of 0.02°C / min to continue the growth of the crystal layer for 3 hours, and the uncrystallized The liquid is discharged out of the crystallizer; the temperature of the crystallizer is raised at a rate of 0.01°C / min to make the crystal layer sweat, and the sweating end point temperature is 45°C, and the molten liquid is drained; the temperature is raised to melt the crystal layer and collected for sampling analysis . Obtain 446g of pure isosorbide with a purity of 99.92%.

Embodiment 2

[0021] 1Kg of sorbitol dehydration product was introduced into a distillation tank, and the content of isosorbide was detected to be 65%. The mixed solution was heated to 170° C., vacuumed, and the vacuum degree was controlled at 320 Pa for vacuum distillation. The distilled low-boiling point fractions were collected and kept at 60°C, and then introduced into the crystallizer that had been filmed, and the crystal layer was grown for 0.8 hours, and then the temperature was lowered at a rate of 0.02°C / min to allow the crystal layer to continue to grow for 3 hours, and the uncrystallized The liquid is discharged out of the crystallizer; the temperature of the crystallizer is raised at a rate of 0.03°C / min to make the crystal layer sweat, and the sweating end point temperature is 55°C, and the molten liquid is drained; the temperature is raised to melt the crystal layer and then collected for sampling analysis . Obtain 486g of pure isosorbide with a purity of 99.84%.

Embodiment 3

[0023]1Kg of sorbitol dehydration product was introduced into a distillation tank, and the content of isosorbide was detected to be 63%. The mixed solution was heated to 185° C., vacuumed, and the vacuum degree was controlled at 320 Pa for vacuum distillation. The distilled low-boiling point fractions were collected and kept at 65°C, and then introduced into the crystallizer that had been filmed, and the crystal layer was grown for 1 hour, and then the temperature was lowered at a rate of 0.03°C / min to allow the crystal layer to continue to grow for 3.5 hours, and the uncrystallized The liquid is discharged out of the crystallizer; the temperature of the crystallizer is raised at a rate of 0.05°C / min to make the crystal layer sweat, and the sweating end point temperature is 55°C, and the molten liquid is exhausted; the temperature is raised to melt the crystal layer and then collected for sampling analysis . Obtain 522g of pure isosorbide with a purity of 99.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com