Method for treating gasified waste water containing high-concentration phenol and ammonia

A coal gasification sewage, high-concentration technology, applied in chemical instruments and methods, ammonia preparation/separation, organic compound preparation, etc., can solve the problem of increasing the dephenolization load in the biochemical treatment section, the unsatisfactory polyphenol extraction effect, and affecting equipment. problems such as normal operation, to achieve the effect of improving the effect of dephenolization, alleviating the problems of ammonia salt crystallization and scaling, and ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

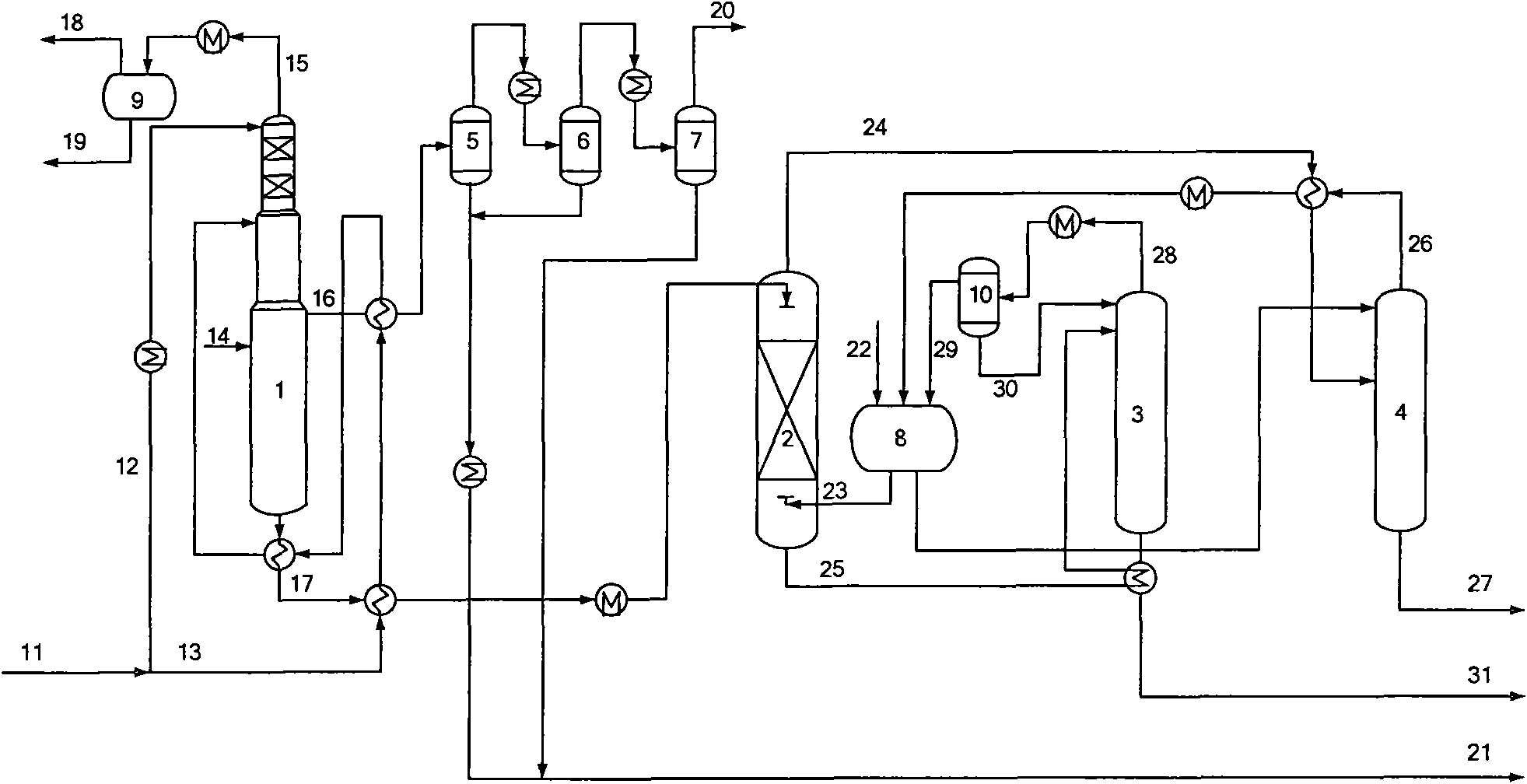

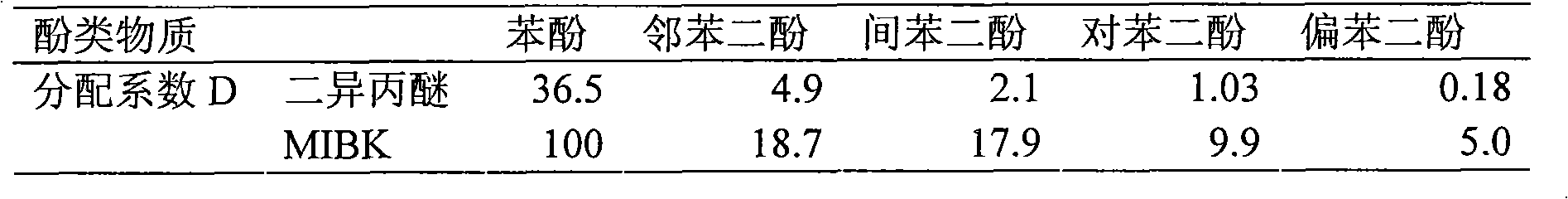

[0028] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 5018 mg L -1 , free ammonia 4012mg·L -1 , fixed ammonia 2036mg·L -1 , CO 2 8072mg·L -1 , the pH value is 9.5, the water temperature is 88°C, the flow rate is 100 tons / hour, according to figure 1 process shown. The cold and hot feed ratio of the sewage stripping tower is 1:4, the temperature at the top of the tower is 61.5°C, the pressure at the top of the tower is 0.62MPa, the temperature at the bottom of the tower is 161°C, the pressure at the bottom of the tower is 0.648MPa, the mass percentage concentration is 20% caustic soda aqueous solution flow rate is 413kg· hr -1 , the temperature of the side line production is 146.0°C, and the pressure is 0.62MPa. The operating pressure of the first stage partial condenser is 0.51MPa, the operating temperature is 135.4°C, the operating pressure of the se...

Embodiment 2

[0030] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 6523mg L -1 , free ammonia 4311mg·L -1 , fixed ammonia 1807mg·L -1 , CO 2 6037mg·L -1 , the pH value is 9.8, the water temperature is 88°C, the flow rate is 80 tons / hour, according to figure 1 process shown. The cold and hot feed ratio of the sewage stripping tower is 1:3.5, the temperature at the top of the tower is 58°C, the pressure at the top of the tower is 0.582MPa, the temperature at the bottom of the tower is 159°C, the pressure at the bottom of the tower is 0.622MPa, the mass percentage concentration is 18% caustic soda aqueous solution flow rate is 382.5kg ·hr -1 , the temperature of the side line production is 143.4°C, and the pressure is 0.59MPa. The operating pressure of the first stage partial condenser is 0.46MPa, the operating temperature is 137°C, the operating pressure of the seco...

Embodiment 3

[0032] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 5218mg L -1 , free ammonia 4541mg·L -1 , fixed ammonia 1540mg·L -1 , CO 2 6423mg·L -1 , the pH value is 9.2, the water temperature is 70°C, the flow rate is 90 tons / hour, according to figure 1 process shown. The cold and hot feed ratio of the sewage stripping tower is 1:4, the temperature at the top of the tower is 55°C, the pressure at the top of the tower is 0.55MPa, the temperature at the bottom of the tower is 155°C, the pressure at the bottom of the tower is 0.61MPa, the mass percentage concentration is 25% caustic soda aqueous solution flow rate is 354kg. hr -1 , the temperature of the side line production is 149.2°C, and the pressure is 0.571MPa. The operating pressure of the first stage partial condenser is 0.432MPa, the operating temperature is 125.7°C, the operating pressure of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com