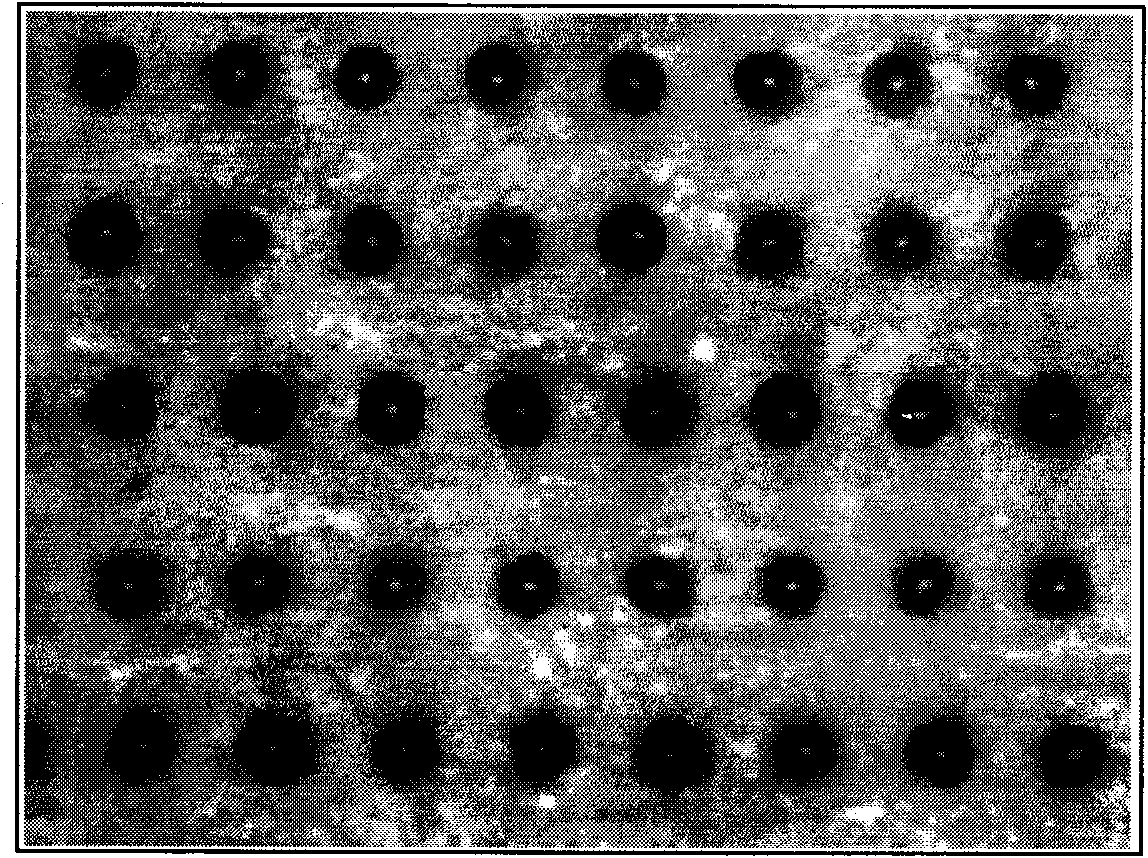

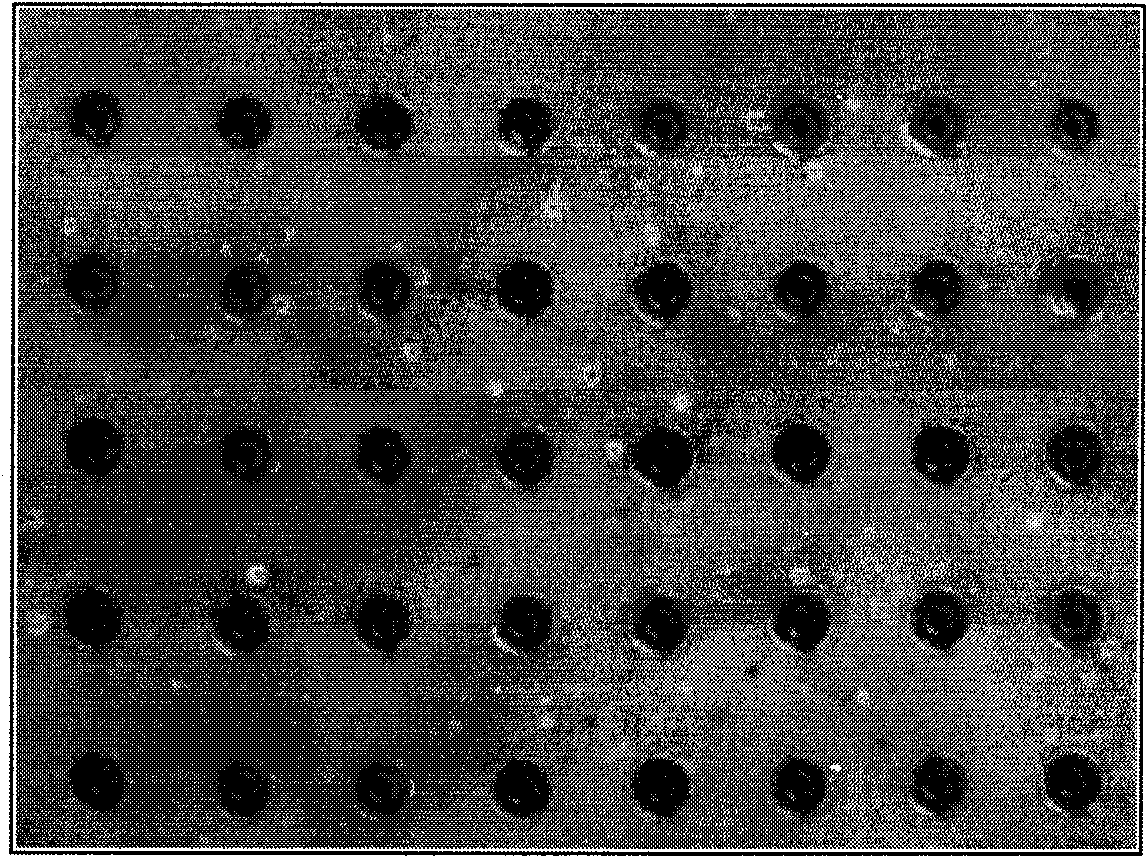

Packaging substrate with tactile images

A technology of substrates and images, applied in the field of packaging substrates with tactile images and their formation, can solve the problems of increasing the cost of printing flexible substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] A UV curable phase change gelling ink was prepared containing 7.5% by weight of the curable amide gellant described in Example VIII of US Patent 7,279,587 (which is incorporated herein by reference in its entirety), 5% by weight of Unilin 350 TM Acrylates, 5% by weight of pentafunctional acrylate monomer (SR 399LV dipentaerythritol pentaacrylate, available from Sartomer Co., Inc.), 52.8% by weight of difunctional acrylate monomer (propoxylated Neopentyl glycol diacrylate SR 9003, available from Sartomer Co., Inc.), 3% by weight of 379 photoinitiator (available from Ciba Specialty Chemicals), 1% by weight of 819 Photoinitiator (available from Ciba Specialty Chemicals), 3.5% by weight of 127 Photoinitiator (available from Ciba Specialty Chemicals), 2% by weight of ITX photoinitiator (available from Ciba Specialty Chemicals), and 0.2% by weight of UV stabilizer ( UV10, available from Ciba Specialty Chemicals). All said components were stirred together at 90° C. fo...

Embodiment 2

[0189]Prepare a kind of ultraviolet curable phase-change gelled ink, this ink contains the curable amide gellant described in 7.5% by weight of U.S. Patent 7,279,587 embodiment VIII, 5% by weight according to U.S. Patent Publication 2007120925 (which is incorporated by reference in its entirety) Incorporate Unilin 350 prepared as described in this article) TM Acrylate wax, 5% by weight pentafunctional acrylate monomer (SR 399LV dipentaerythritol pentaacrylate, available from Sartomer Co., Inc.), 72.8% by weight difunctional acrylate monomer (propoxy Neopentyl glycol diacrylate SR 9003, available from Sartomer Co., Inc.), 3% by weight 379 photoinitiator (obtained from Ciba Specialty Chemicals), 1% by weight of 819 photoinitiator (obtained from Ciba Specialty Chemicals), 3.5% by weight of 127 photoinitiator (obtained from Ciba Specialty Chemicals), 2% by weight of ITX photoinitiator (obtained from Ciba Specialty Chemicals), and 0.2% by weight of UV stabilizer ( UV10, ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com