Hammer drill

A technology of hammer drill and cylinder, applied in the field of hammer drill, can solve the problems of high cost, high manufacturing requirements, large space, etc., and achieve the effects of reduced production cost, compact structure, and low manufacturing and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

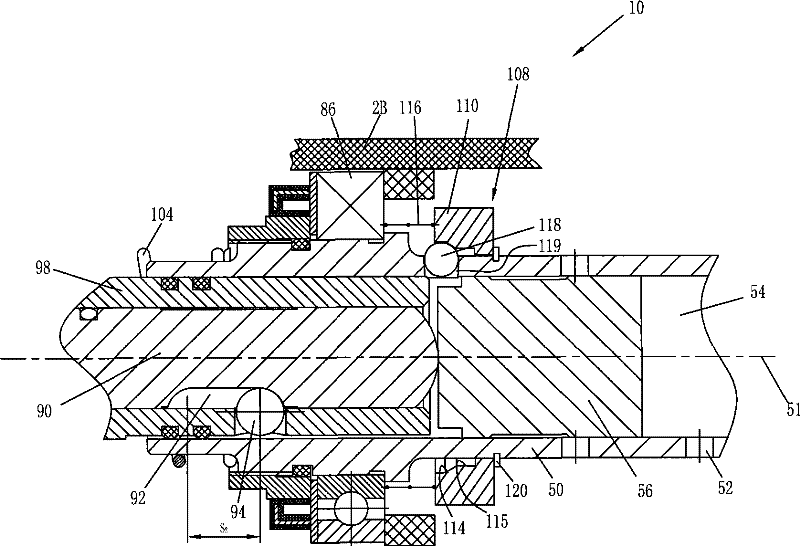

[0066] see attached below Figure 1-8 , The hammer drill 1 according to the first embodiment of the present invention includes a housing 2, a motor 33, an operating tool 28, an impact force transmission mechanism 30, a rotational force transmission mechanism 31, a switching mechanism 10, and the like. The hammer drill 1 can be operated in a rotary and percussion mode (hammer drill), percussion only mode (hammer), rotary only mode (drill) and an intermediate mode (hammer swivel).

[0067] The hammer drill 1 includes a handle 4 provided on the rear end of the housing 2, a switch 6 provided on the handle 4, a cable 8 connected to the handle 4 for supplying electric power to the hammer drill 1, rotatably provided on the housing A switch mechanism 10 on the body 2 for switching operation modes, and an auxiliary handle 26 arranged near the front end of the housing 2 . The operating tool 28 is attached to the front end of the hammer drill 1 via a chuck 96 . The operating tool 28 re...

no. 2 example

[0105] Refer to attached Figure 9-11, illustrates a hammer drill 1A of a second embodiment of the present invention. In the second embodiment, the basic structure of the hammer drill 1A is the same as that of the first embodiment, therefore, the reference numerals of the corresponding components are also the same. Only the different parts are explained here.

[0106] In this embodiment, the limit mechanism 208 limits the axial displacement of the punch 90 .

[0107] The punch 90 is in direct contact with the operating tool 28 . The punch 90 includes a front end in contact with the operating tool 28 and a rear end accommodated in the cylinder 50. A slide groove 92 is arranged radially from the outer wall and extends axially. A rolling element 94 is arranged between the cylinder 50 and the punch 90 and is accommodated in the slide groove. 92 , the punch 90 moves relative to the cylinder 50 between the end of the rolling member 94 located in the chute 92 adjacent to the front...

no. 3 example

[0120] Refer to attached Figure 12-15 , illustrates a hammer drill 1B of a third embodiment of the present invention. In the third embodiment, the basic structure of the hammer drill 1B is the same as that of the first embodiment, therefore, the reference numerals of the corresponding components are also the same. Only the different parts are explained here.

[0121] The limiting mechanism 308 limits the axial displacement of the impact block 56A.

[0122] The impact block 56A is accommodated in the cylinder 50 and can cross the through hole 52 in the axial direction, so as to keep the through hole 52 in fluid communication with the air chamber 54 or cut off the fluid communication between the through hole 52 and the air chamber 54 . When the through hole 52 is sealed, the impact block 56A will reciprocate in the cylinder 50 to exert an impact force on the punch 90 . Both the collet sleeve 98 and the punch 90 can move axially relative to the cylinder 50, and the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com