Mold for bending bridge partitions

A mold machine and mold technology are applied in the field of mold machines for bending iron partitions of bridges, which can solve the problems of waste of resources, waste of oxygen acetylene and electric welding electrodes, low efficiency, etc., and achieve the effect of improving work efficiency and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

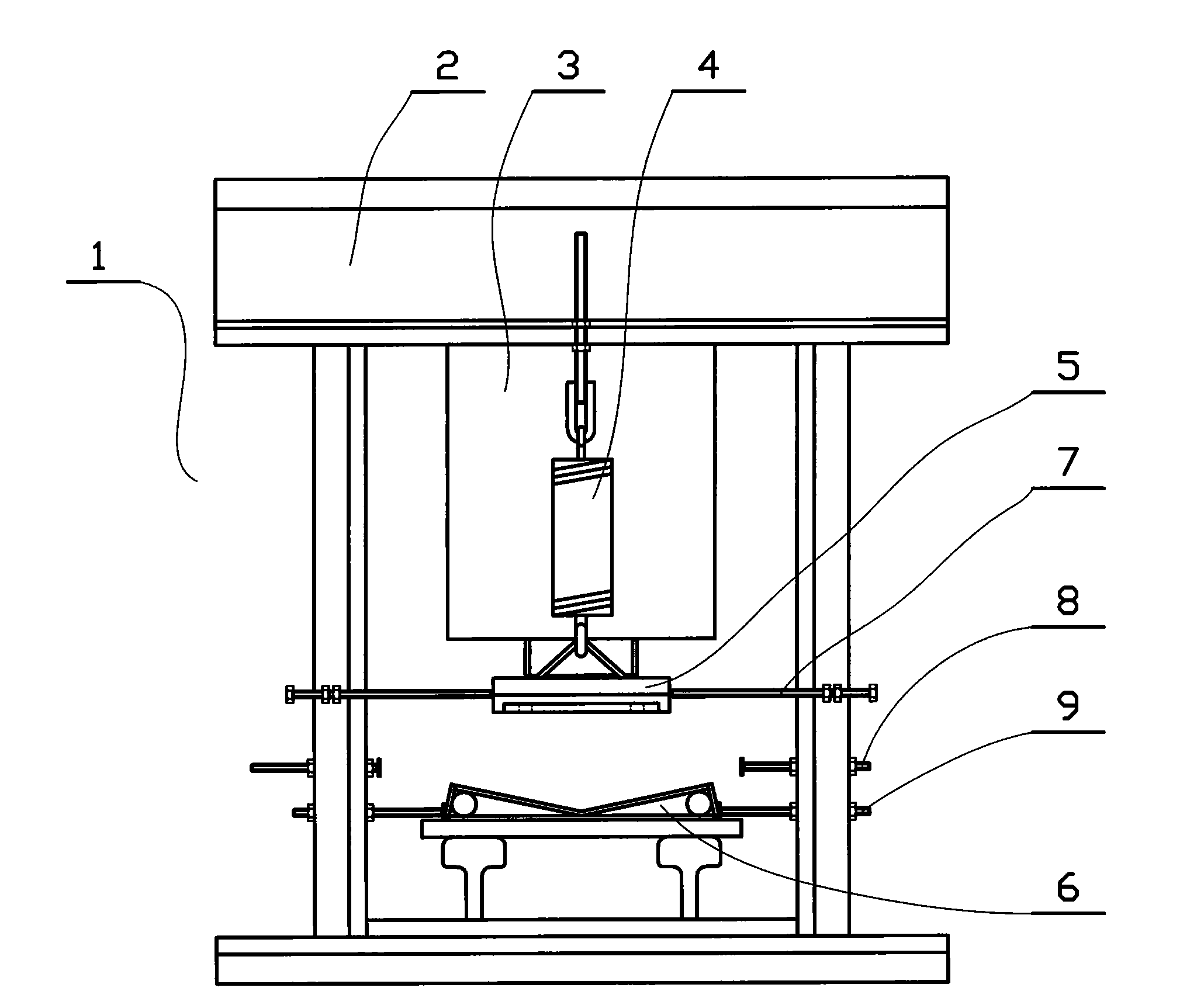

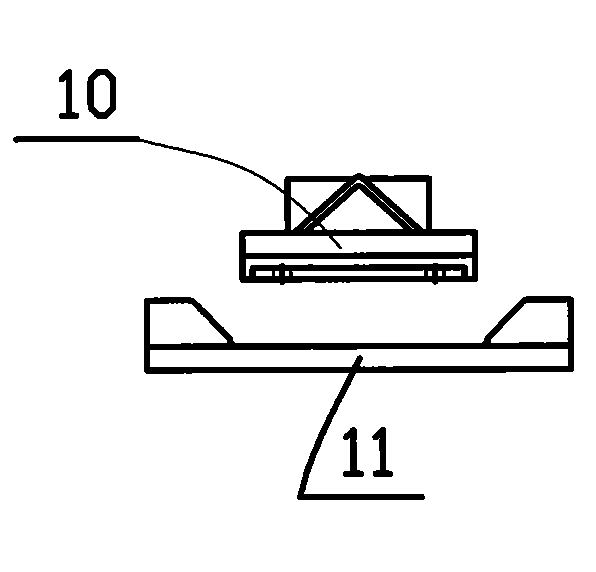

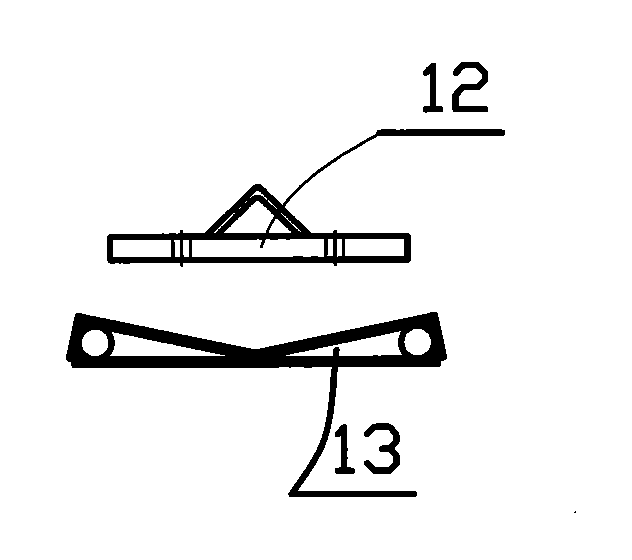

[0016] like figure 1 and figure 2 As shown, the shown frame 1 is composed of a bottom plate at the bottom and a gantry frame 2 welded together with the bottom plate. The front and rear ends of the shown gantry frame 2 are open, and the two vertical plates on the left and right are A gantry frame 2 is formed with the flat plate at the top of the two vertical slabs; the inside of the gantry frame shown has a jack 3 reversely arranged on the top plate, the specification of the jack 3 is 200 tons, and the top of the jack 3 is a mid-span partition Mould, shown gantry frame bottom plate is provided with a mid-span partition lower mold that is used to match with the mold on the aforementioned mid-span partition, the raw material of the partition that needs to be processed is fixed on the lower mold 6, and can be processed; in order to improve Processing eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com