Emulsion high-pressure automatic back-flushing filtering device

A technology for backwashing filtration and emulsification, which is used in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of filter element rupture, low work efficiency, increased resistance, etc. The effect of easy disassembly and assembly of the filter element and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

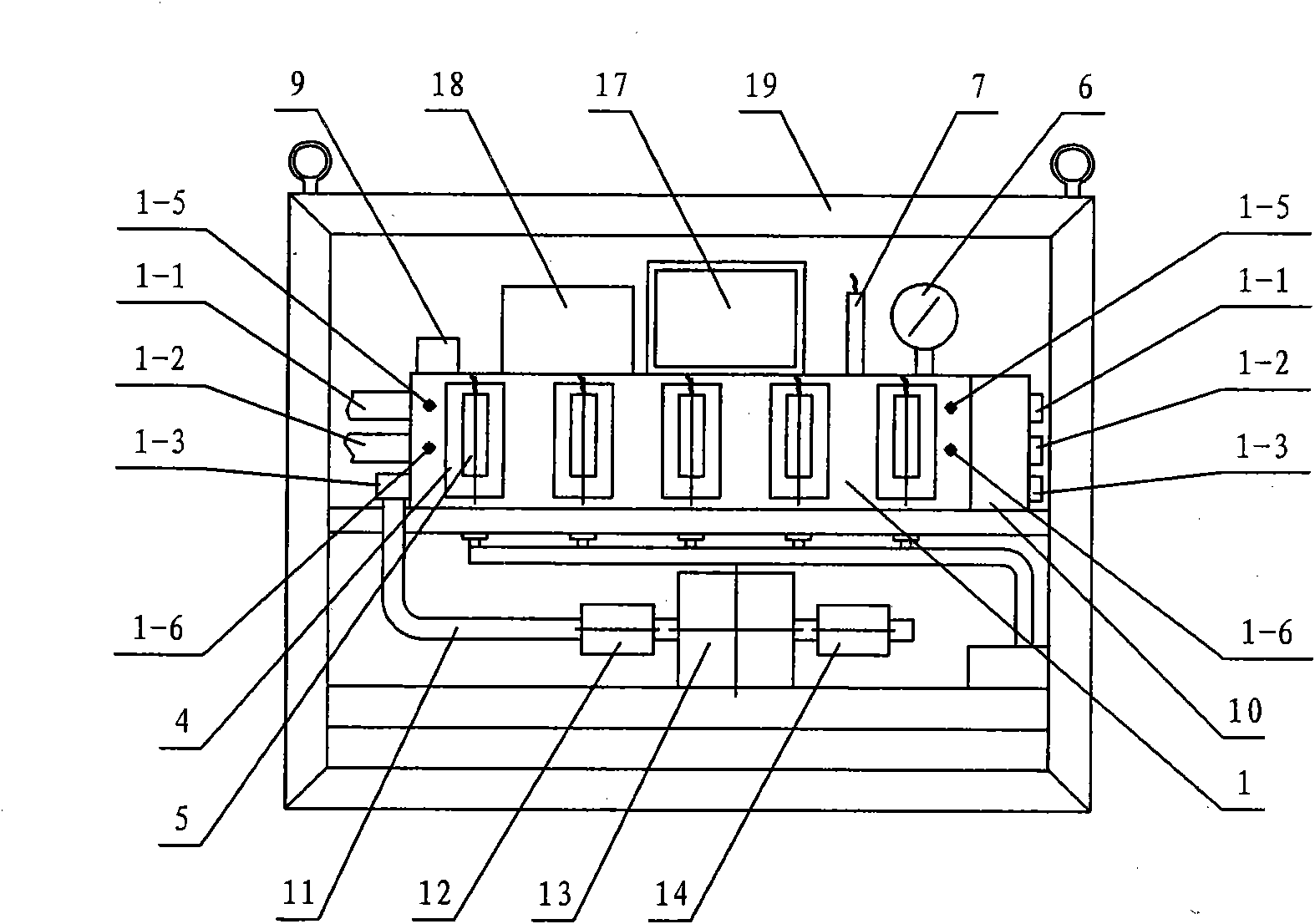

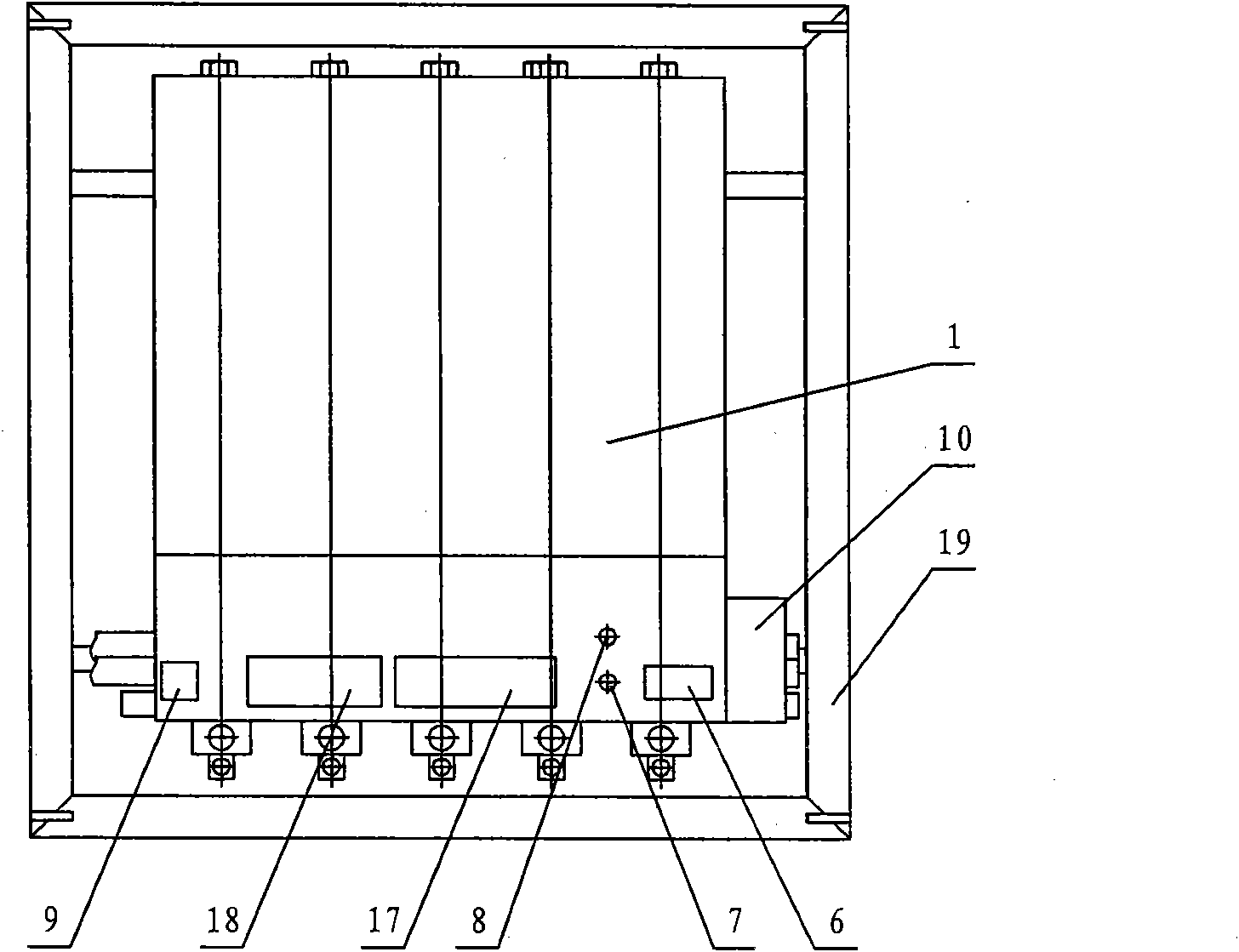

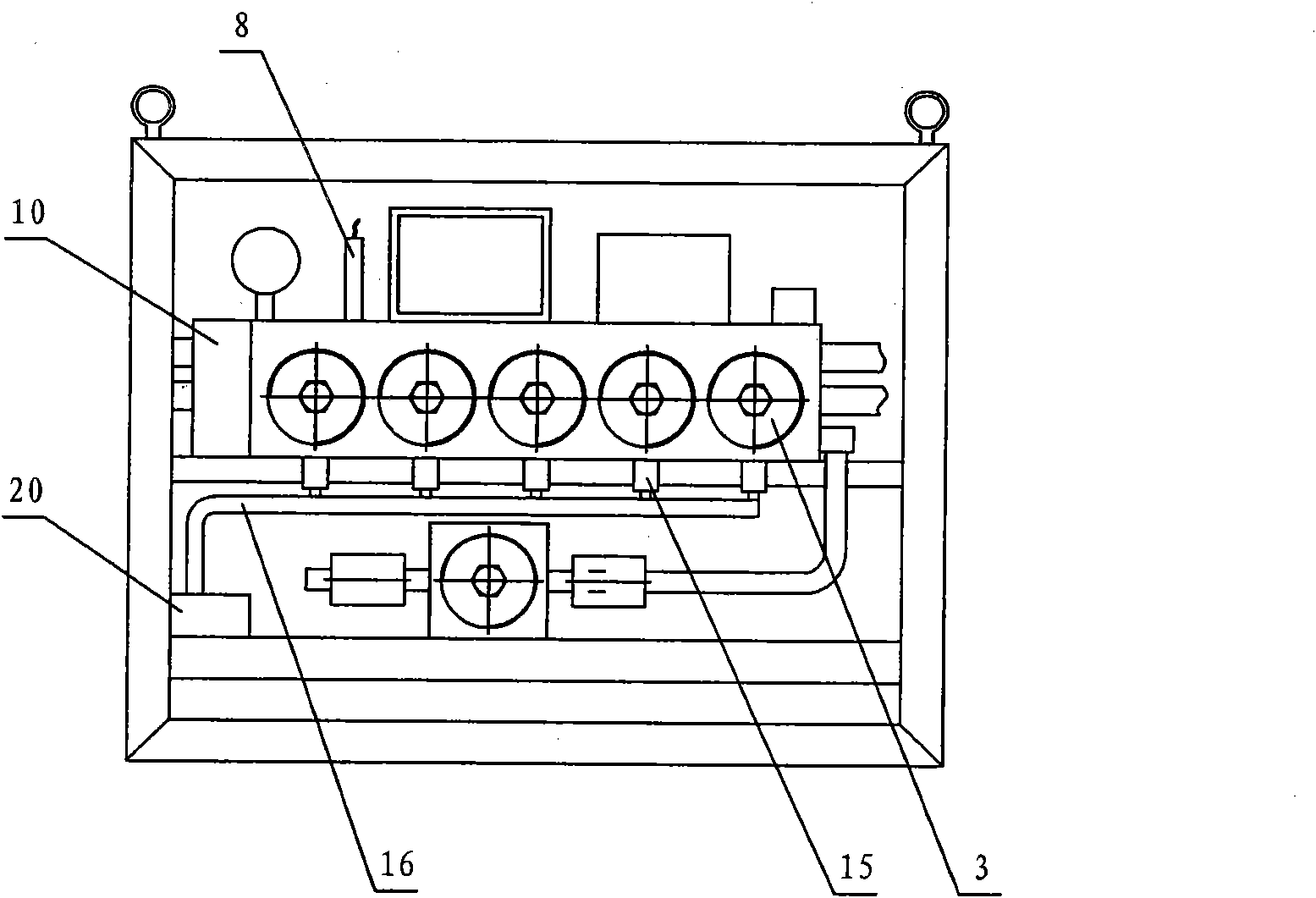

[0022] Description of drawings and specific implementation of the present invention, take a group of filter units as an example, open five filter holes 1-4 on the filter body, install five filter cores 2, that is, the flow rate of one group of filter units is 1000L / min. For example, according to the needs of the working flow, two or more filter units can be used, and the filter bodies 1 can be stacked or placed in parallel, connected in parallel or connected in series.

[0023] Such as Figure 1 to Figure 7 As shown, the emulsion high-pressure automatic backwash filter device includes at least one set of filter units, a backwash sewage system (a sewage pipeline 11, a sewage overflow valve 12, a sewage filter 13, a back pressure valve 14), a power supply box 18, a frame 19, a liquid receiving tank 20, accessories, etc., each filter unit includes a set of filter assemblies, five backwash reversing valves 4, five electromagnetic pilot valves 5, a safety valve 10, manual exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com