Yoghurt containing beta vulgaris particles and production method thereof

A granule and yogurt technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of large nutritional loss, no yogurt technology report, and inability to meet the various requirements of nutrition, health, and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

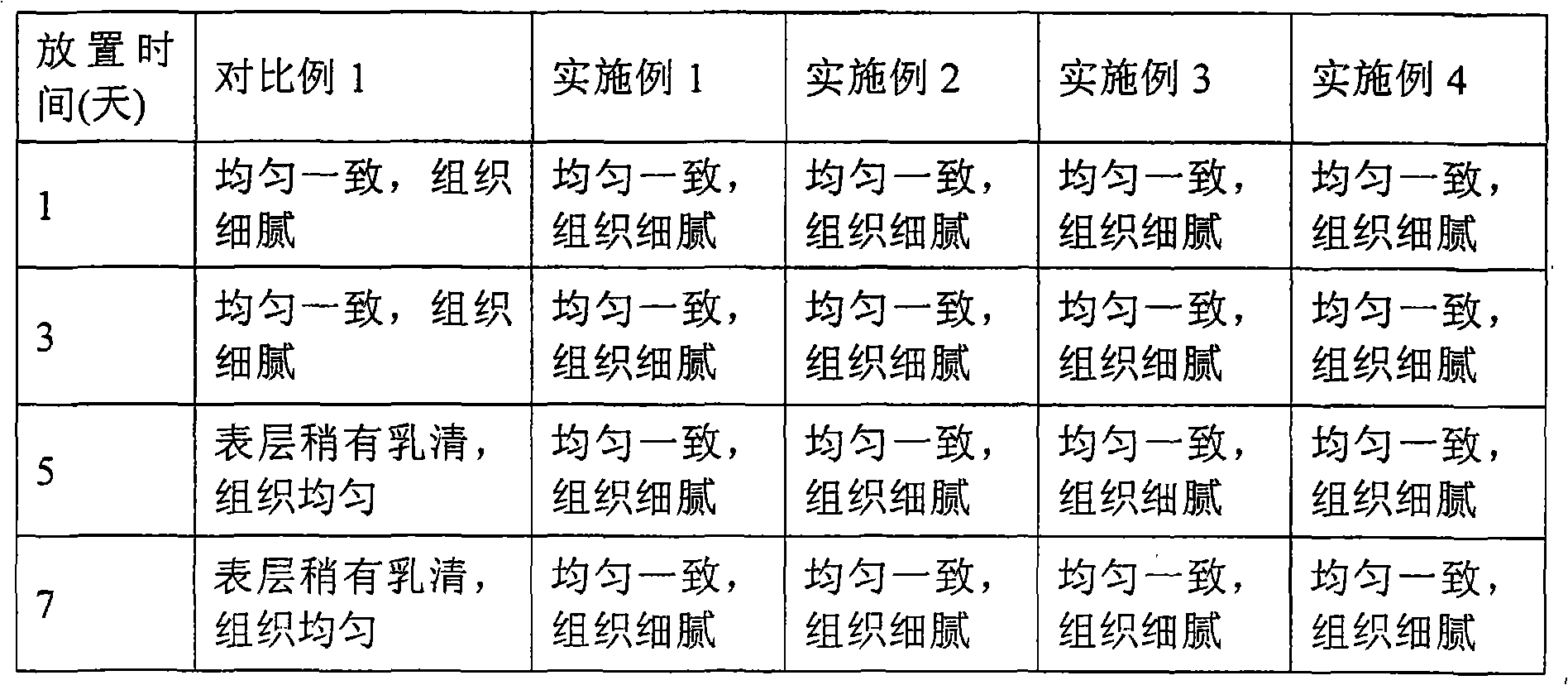

Embodiment 1

[0037] Embodiment 1, the yoghurt that contains sugar beet particle and production method thereof

[0038] Raw material formula (according to 1 ton):

[0039] Yogurt Base 850Kg

[0040] Beet jam (diced beetroot products) 150Kg

[0041] The yoghurt containing beet granules of the present embodiment is prepared according to the following method:

[0042] 1. Production of yogurt base material

[0043] The formula (per 100g) of yogurt base material in the present embodiment: whole milk powder 2g, skimmed milk powder 1.0g, whey protein powder 0.3g, yogurt stabilizer (selected from pectin, modified starch, CMC, xanthan gum, etc. One or more) 0.5g, white sugar 5g, sweetener 0.05g, appropriate amount of lactic acid bacteria (Streptococcus thermophilus, Lactobacillus delbrueckii (subsp.bulgaricus)), fresh milk (fresh milk or reconstituted milk or a combination of both) to make up the balance.

[0044] Fermentation process of yogurt base material: raw milk inspection → milk collecti...

Embodiment 2

[0078] Embodiment 2, yoghurt containing beet granules and production method thereof

[0079] Raw material formula (according to 1 ton):

[0080] Yogurt Base 900Kg

[0081] Beet jam (shredded beet root products) 100Kg

[0082] In this embodiment, the production of the yoghurt base material is basically the same as in Embodiment 1.

[0083] Beet granules are made into filaments of 1-3mm×1-3mm×3-8mm, the concentration of fermented brine is 6%, the pH of the fermentation liquid is 4.5 when the fermentation is finished, and the fermented beet silk is soaked in sterilized water at room temperature for 30 minutes , and then in 20% white granulated sugar solution for room temperature icing for about 30 minutes, the beet shreds obtained after the treatment have improved brittleness and reduced hardness, while eliminating the vegetable smell and having a sweet and sour taste. The fermented beet silk is prepared into a jam with a beet silk content of about 50%. The preparation method ...

Embodiment 3

[0085] Embodiment 3, yoghurt containing beet granules and production method thereof

[0086] Raw material formula (according to 1 ton):

[0087] Yogurt Base 820Kg

[0088] Beet jam (shredded beetroot product) 80Kg

[0089] Carrot jam (shredded carrot products) 30Kg

[0090] Pineapple Jam 70Kg

[0091] In this embodiment, the production of the yoghurt base material is basically the same as in Embodiment 1. Beet granules are made into filaments of 1-3mm×1-3mm×3-8mm, the concentration of beet fermented brine is 8%, and the preparation of beet jam is basically the same as in Example 2. Carrot jam is prepared by the same process as beet jam. It is sticky and has a certain fluidity. The soluble solid content Brix (%) is 33, and the pH value (20°C) is about 3.5. Carrot shreds are suspended in it, and the net content of carrot shreds is About 45%, the size is about 1-3mm×1-3mm×5-10mm, it has the color that fresh carrots should have, has the taste and smell of fermented carrots, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com