Large-scale aseptic-manipulation continuous production equipment

A production device and aseptic operation technology, which is applied in the field of inoculation device and material transportation, can solve the problems of low input and high output, large capital investment and high cost, so as to maintain high efficiency and continuity and reduce labor. Powerful, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

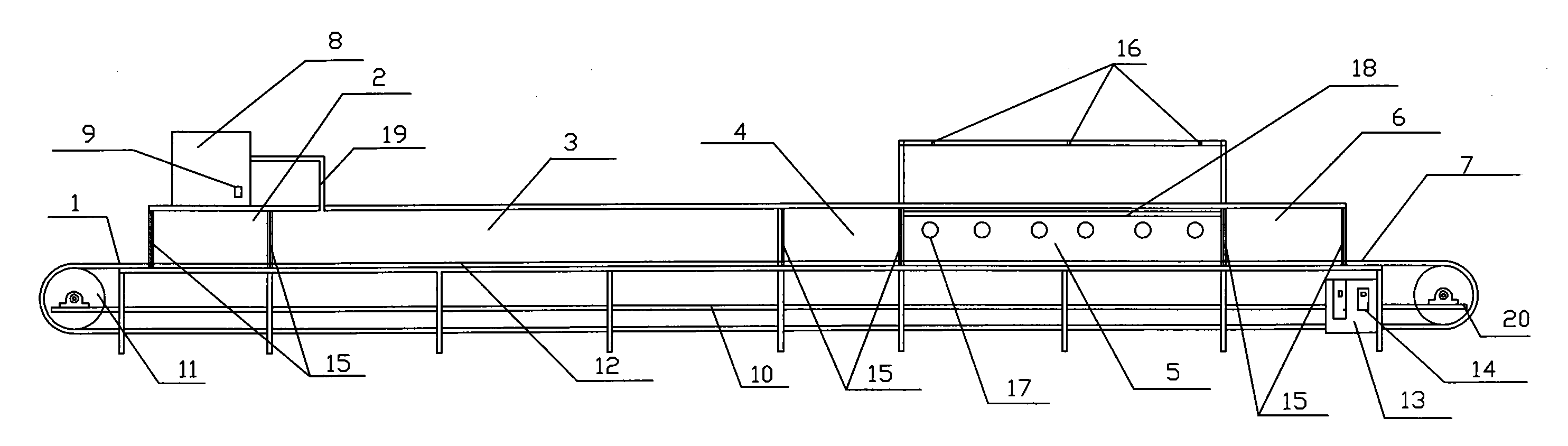

[0010] Such as figure 1 As shown, the present invention is provided with a transmission device on the frame 10, and an inlet platform 1, an inlet buffer bin 2, a disinfection bin 3, a middle buffer bin 4, an inoculation bin 5, and an outlet buffer bin are sequentially arranged above the transfer device from left to right 6, the outlet platform 7, an ozone generator 8 is set above the import buffer storehouse 2, a microcomputer controller 9 is set on the ozone generator 8, the ozone generator 8 is connected with the disinfection storehouse 3 through a pipeline, and buffered at the inlet Movable curtains 15 are respectively set at the entrance and exit of the warehouse 2, the middle buffer warehouse 4, and the outlet buffer warehouse 6, and the moisture-reducing air window 16 is set above the inoculation warehouse 5, and three pairs of protective sleeves 17 are respectively arranged on the inoculation warehouse 5 on both sides. , the setting stage 18 in the inoculation bin 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com