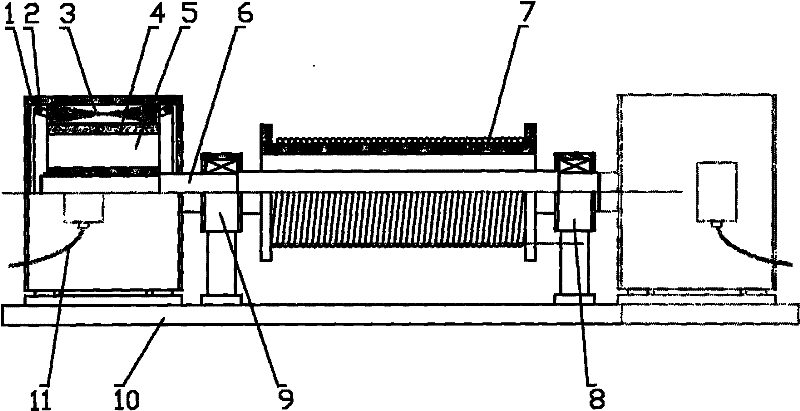

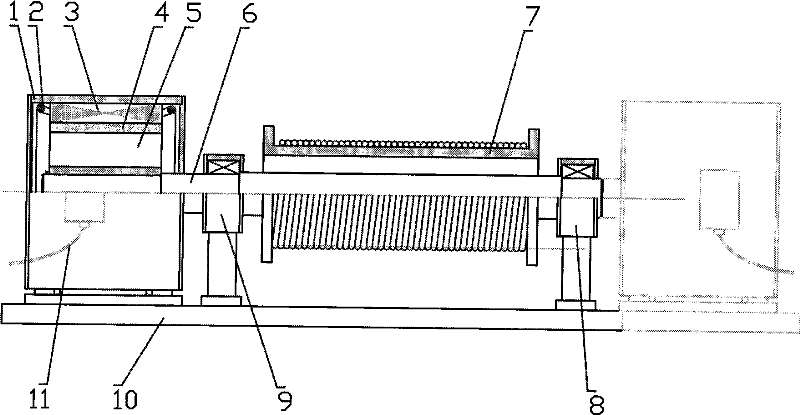

Permanent magnet synchronous motor for hoisting mechanism of direct-drive crane

A permanent magnet synchronization and lifting mechanism technology, applied in the direction of synchronous machines, electromechanical devices, spring mechanisms, etc., can solve problems such as low efficiency, high cost of the drag system, difficult maintenance, etc., to reduce complexity and improve transmission Efficiency and reduced maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

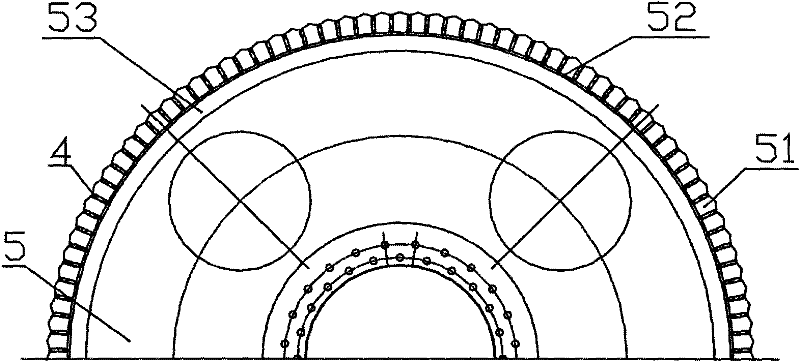

[0031] The specific implementation method of on-site installation: The processing and production of the above-mentioned permanent magnet synchronous motors for the hoisting mechanism of the direct drive crane will be completed in the factory, but the installation process will be completed simultaneously at the assembly site of the hoisting mechanism of the crane. First, assemble the stator and rotor of the motor (without installing permanent magnets) in order, fix the rotor of the motor to the reel shaft, adjust the installation and coordination of the stator and rotor to ensure that the air gap of the motor is uniform, and the rotor of the motor The stator is fixed to the specified position on the working site, and then the permanent magnet is smeared with nano-adhesive and stuffed into the gap between the adjacent rotor poles on the rotor. , complete the installation of the permanent magnet synchronous motor for the hoisting mechanism of the direct-drive crane, and complete t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com