Overflow glue removing mechanism and method thereof

A technology of overflowing glue and chips, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as shrinkage of the connection area, breakage, and drop of the molded chip 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

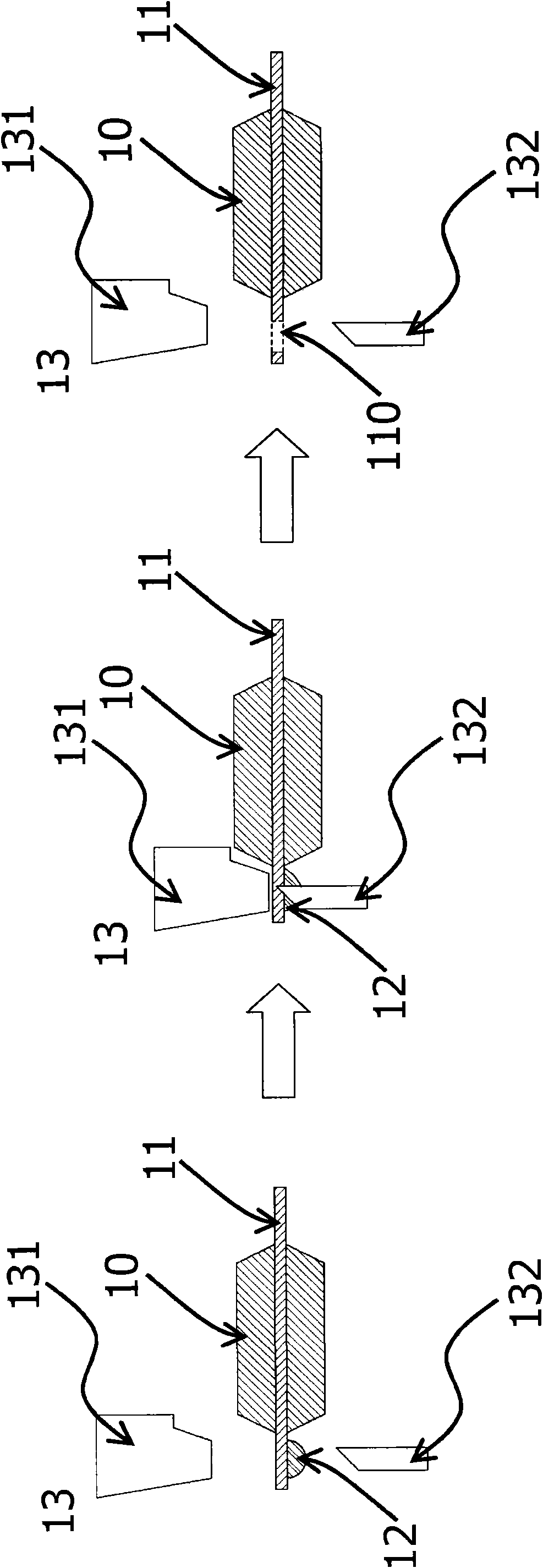

[0013] Since the present invention discloses a glue overflow removal mechanism and its method, which are used to remove the glue overflow on the lead frame of the molded chip, the manufacturing principle and packaging and testing method of the molded chip are already common knowledge in the relevant technical field The reader can understand it, so the following description will not make a complete description. At the same time, the drawings compared below are schematic structural representations related to the features of the present invention, and are not and need not be completely drawn according to actual dimensions, and will be described here first.

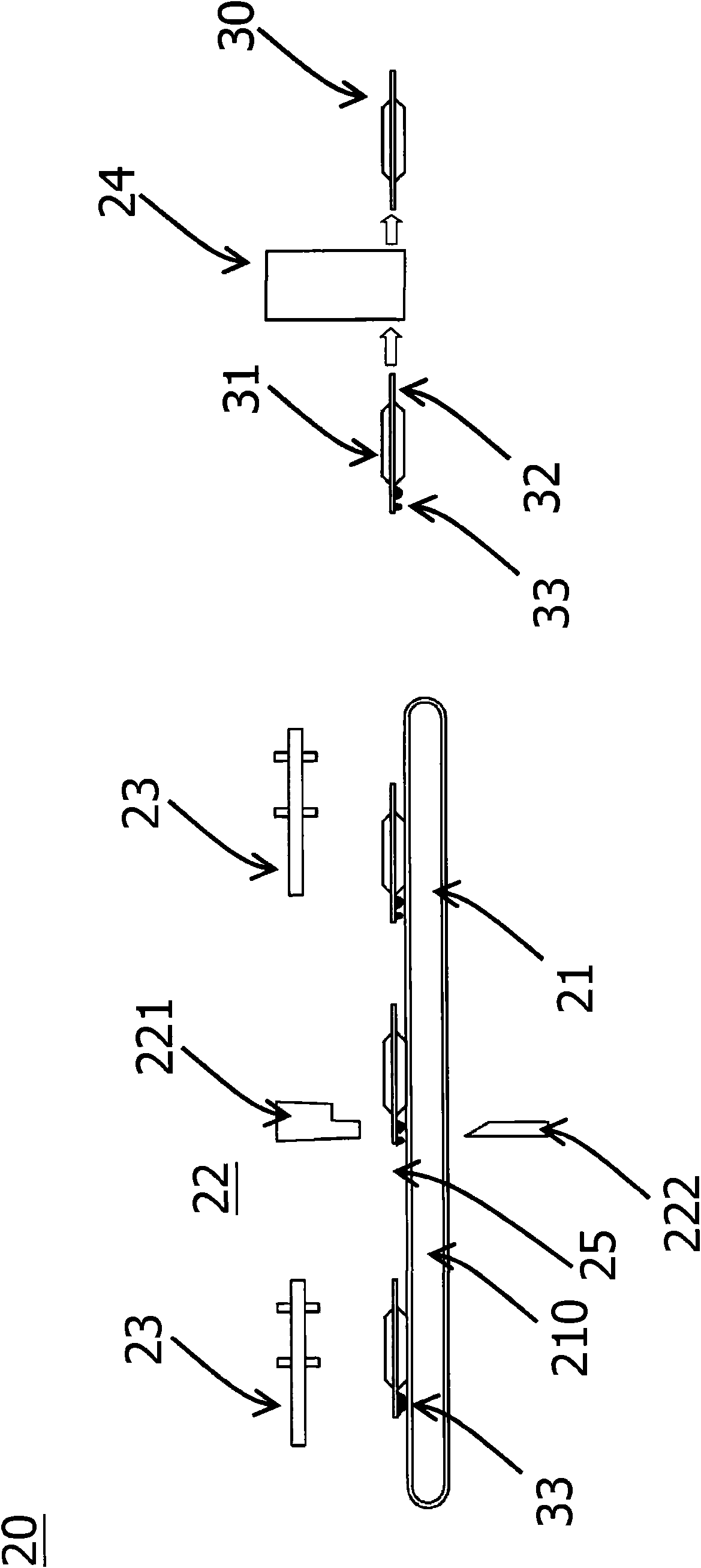

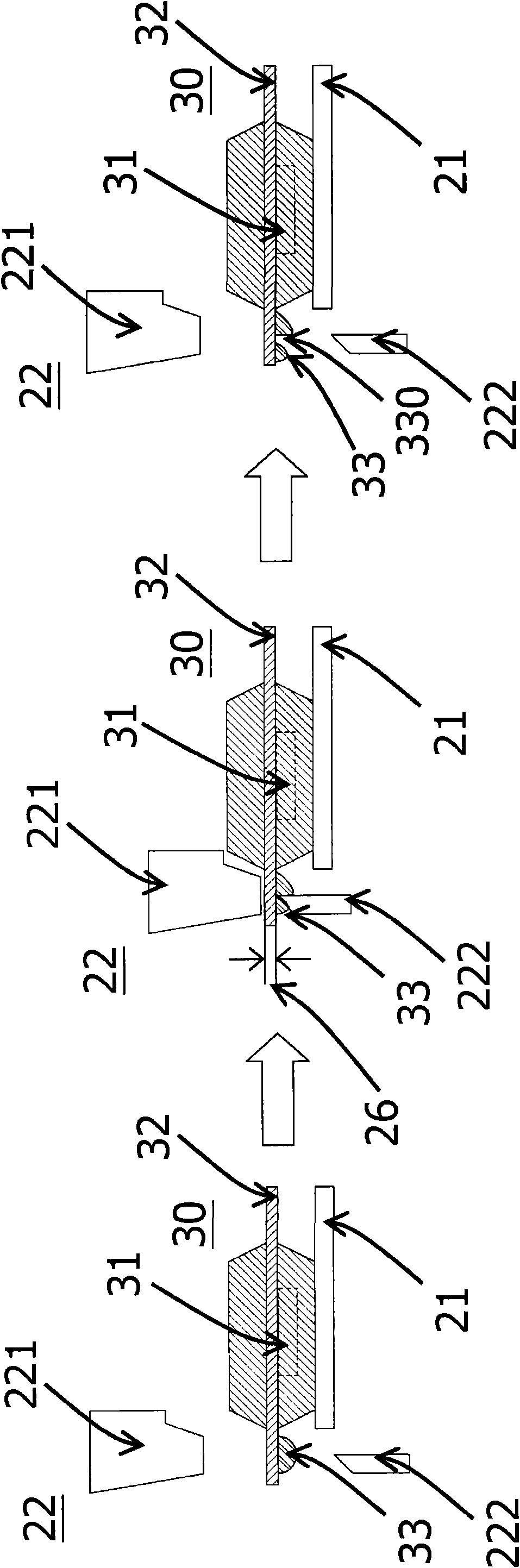

[0014] First please refer to figure 2 , the figure shows the first preferred embodiment of the present invention to remove the glue overflow mechanism 20, which is mainly used to remove the overflow glue on the lead frame of the molded chip, wherein the molded chip 30 includes a chip body 31, Connect the lead frame 32 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com