Method for manufacturing transformer reel and manufacturing machine thereof

A manufacturing method and technology of transformers, which are applied in inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve problems such as production automation and process automation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to further understand the technology, means and effects that the present invention takes to achieve the intended purpose, please refer to the following detailed description and accompanying drawings of the present invention. For specific understanding, however, the accompanying drawings are only for reference and illustration, and are not intended to limit the present invention.

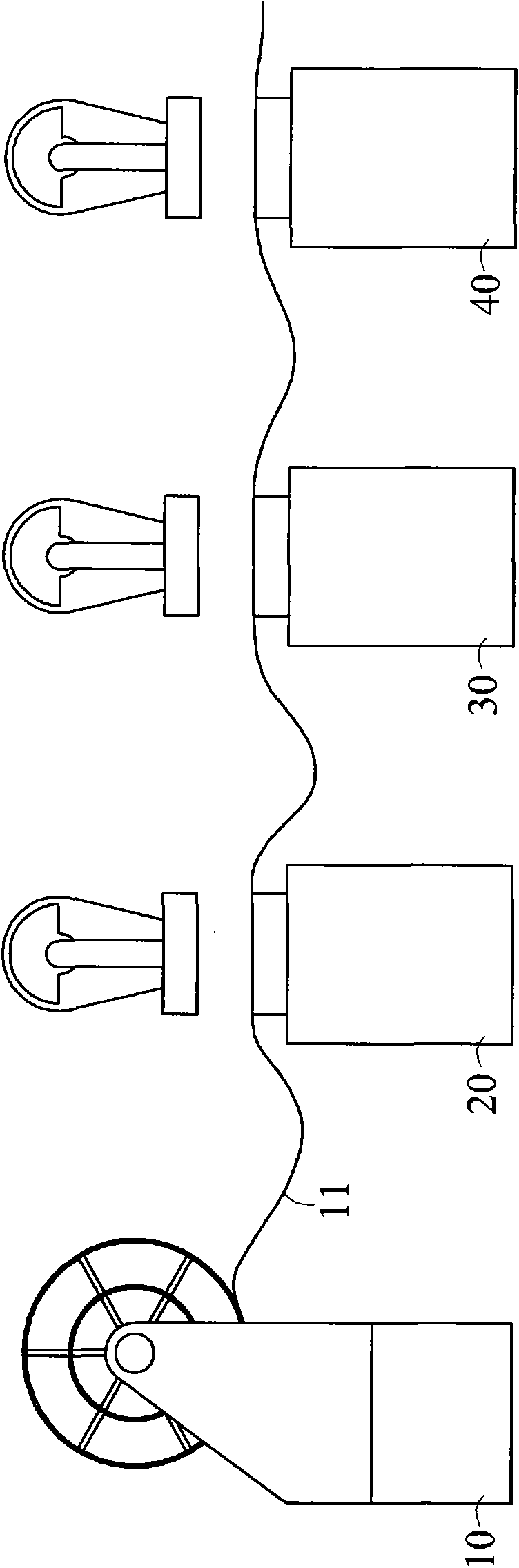

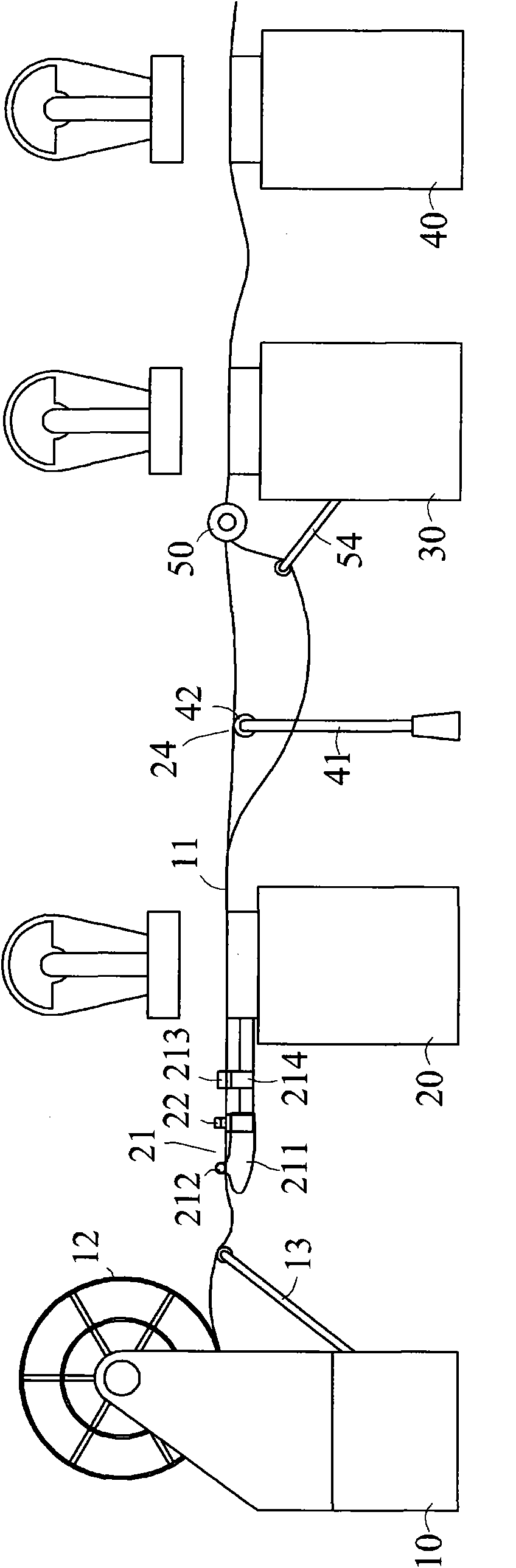

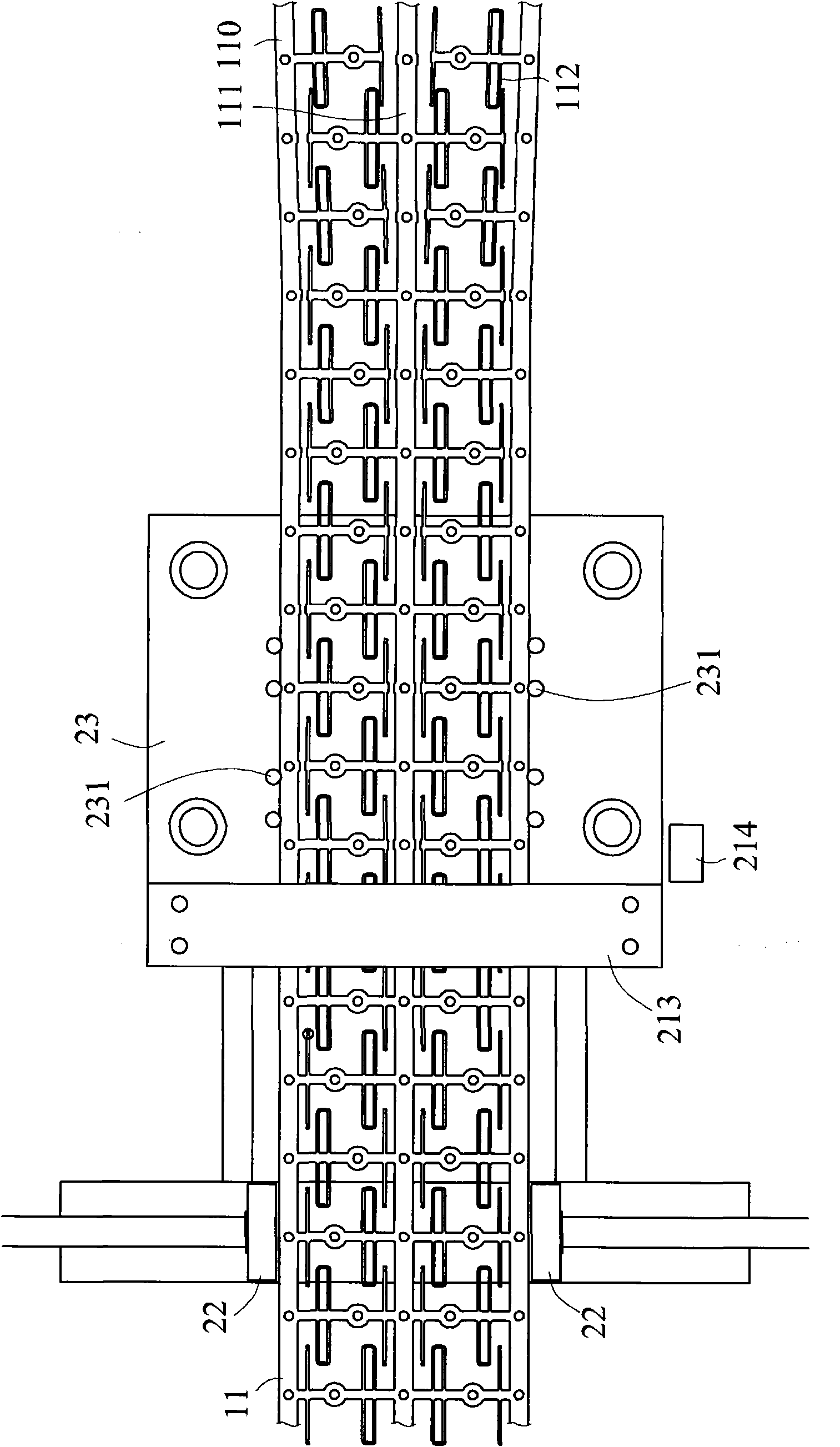

[0067] see figure 1 It is a schematic diagram of the manufacturing machine of the transformer winding frame of the present invention. The manufacturing machine of the transformer winding frame of the present invention includes a feeder 10 , a punching device 20 , an embedded injection molding device 30 , and a cutter 40 . And the manufacture method of the transformer bobbin of the present invention comprises providing a metal conductor material 11; Die-cut this metal conductor material 11, make to be separated into at least two metal conductor materials 11; Align the metal frame on ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com