Passive ceramic substrate-based electronic label special for automobile and manufacturing method thereof

A passive pottery-based, electronic tag technology, applied in the field of radio frequency identification, can solve problems such as irregular sharp fragments, loopholes in vehicle supervision, threats to personal safety of drivers and passengers, etc., and achieve the effect of high grid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

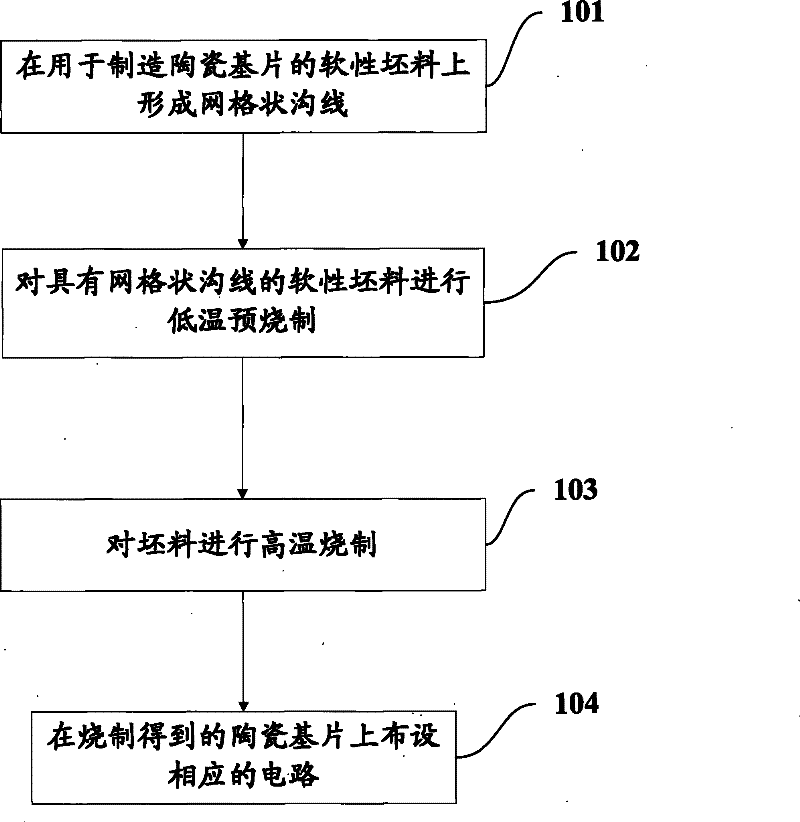

[0028] like figure 1 As shown, in one embodiment of the present invention, the production process of the electronic tag includes the following steps:

[0029] First, in step 101, when the ceramic substrate is in a soft blank, physical treatment is performed on the substrate blank, for example, by means of precise pressing with a special mold, and the engravings on the soft blank are non-uniform in size and asymmetric in position. Arranged grid-like trench lines. This treatment changes the natural distribution of the internal stress of the substrate, so that the substrate has a preset internal stress distributed according to the design requirements, which is equivalent to "implanting" the broken memory line on the substrate, and can only be engraved on the label sticking surface Grid groove lines, that is, "implant" broken memory lines on one side from the direction of the label sticking surface, or implant broken memory lines on both the printed circuit etching surface and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com