Grout stopping machine tool performance testing device

A test device and equipment technology, which is applied to the measurement device, the use of liquid/vacuum for liquid tightness measurement, and the measurement of force, etc., which can solve the lack of a deeper understanding of the force condition and the inability to stop the slurry. The sealing performance monitoring and fixing device of the machine and the stress condition of the sealing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

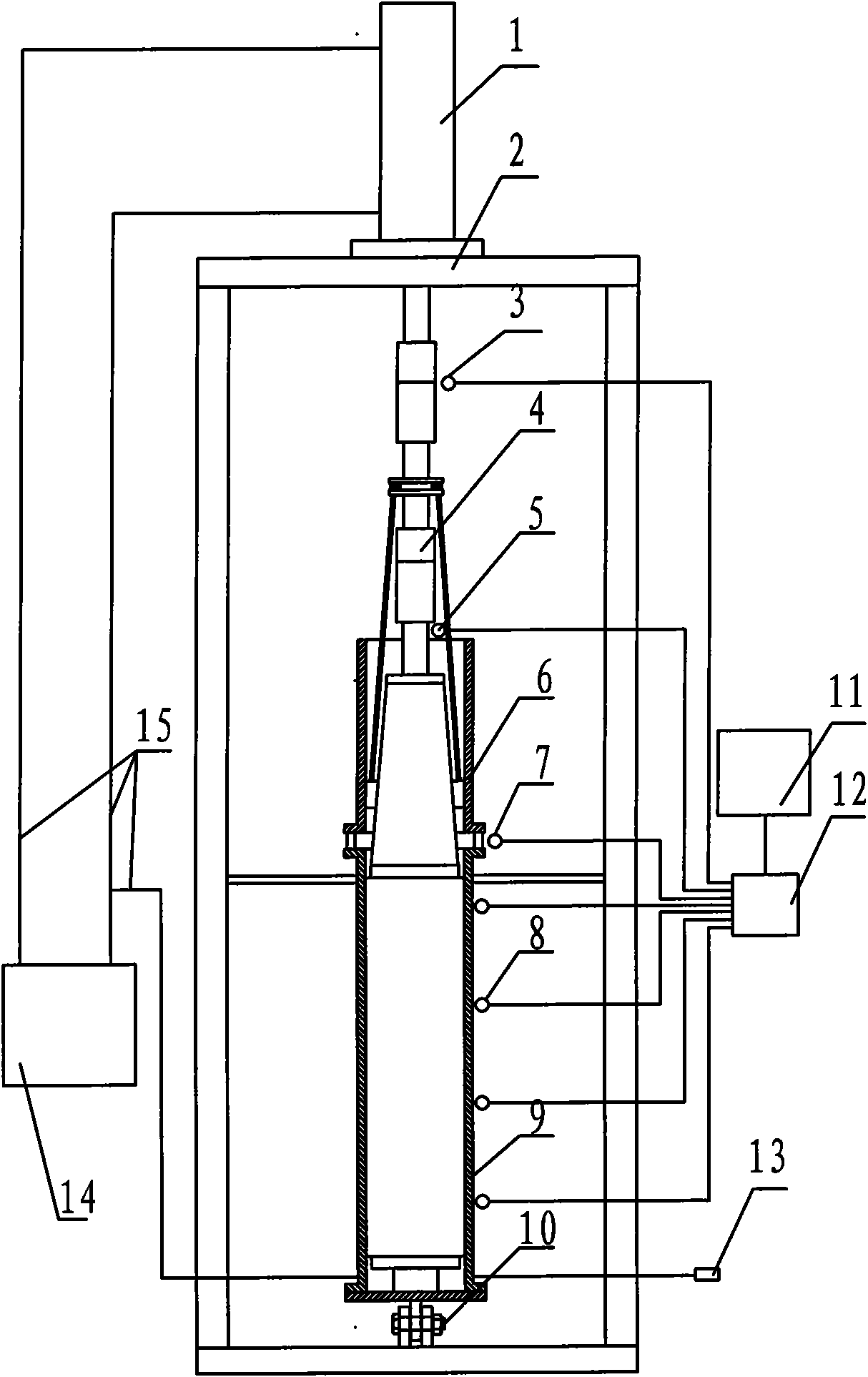

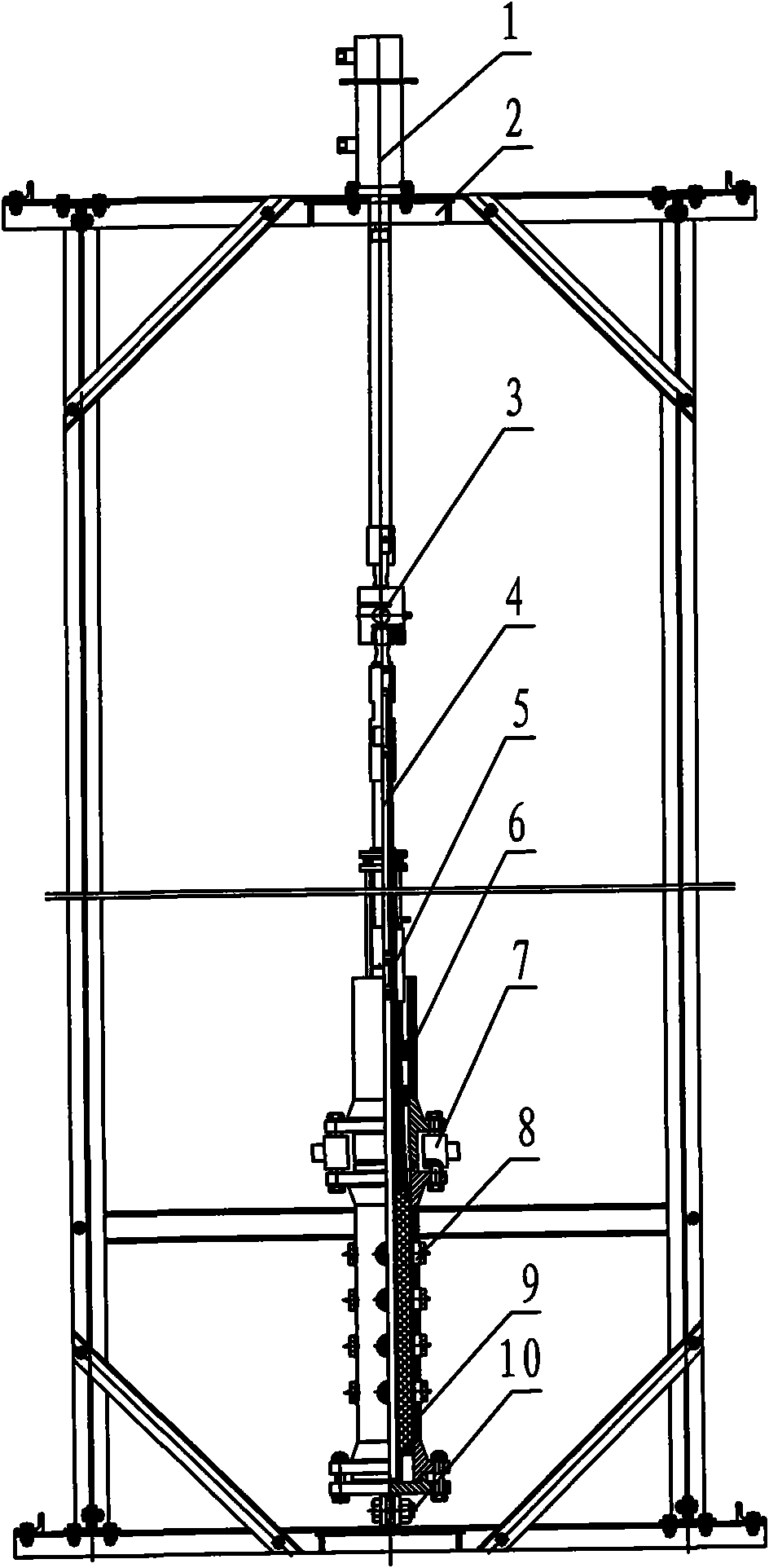

[0012] attached by figure 1 and attached figure 2 As shown, the test device for performance testing of the slurry stopper mainly includes a bracket 2, a stopper to be tested 4, an upper steel pipe mold 6, a lower steel pipe mold 9, and a force sensor 1 3, a force sensor 2 7, and a force sensor 3 8 , the displacement sensor 5 and the data collector 12 connected with the computer 11; wherein the lower steel pipe mold 9 is hinged at the bottom of the support 2, and the lower steel pipe mold 9 is flanged to the upper steel pipe mold 6, and a load cell 27 is arranged at the connection disposal, and In the cavity of its mold (6, 9) is built-in the anti-slurry tool 4 to be tested, the piston of the hydraulic cylinder 1 is connected to the upper end of the anti-slurry tool 4 to be tested and a load cell-3 is arranged; The sealing device is equipped with a displacement sensor 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com