Fixed connection structure used for high speed railway sound barrier transparent cell boards

A technology for high-speed railways and unit panels, applied in noise absorption devices, buildings, etc., can solve the problems of sound barrier structure, material connection mode limitation, insufficient connection strength of unit panel sound barrier column, unit panel resonance, etc., to reduce fatigue Effects of stress, acceleration of vibration attenuation, and reduction of resonance amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

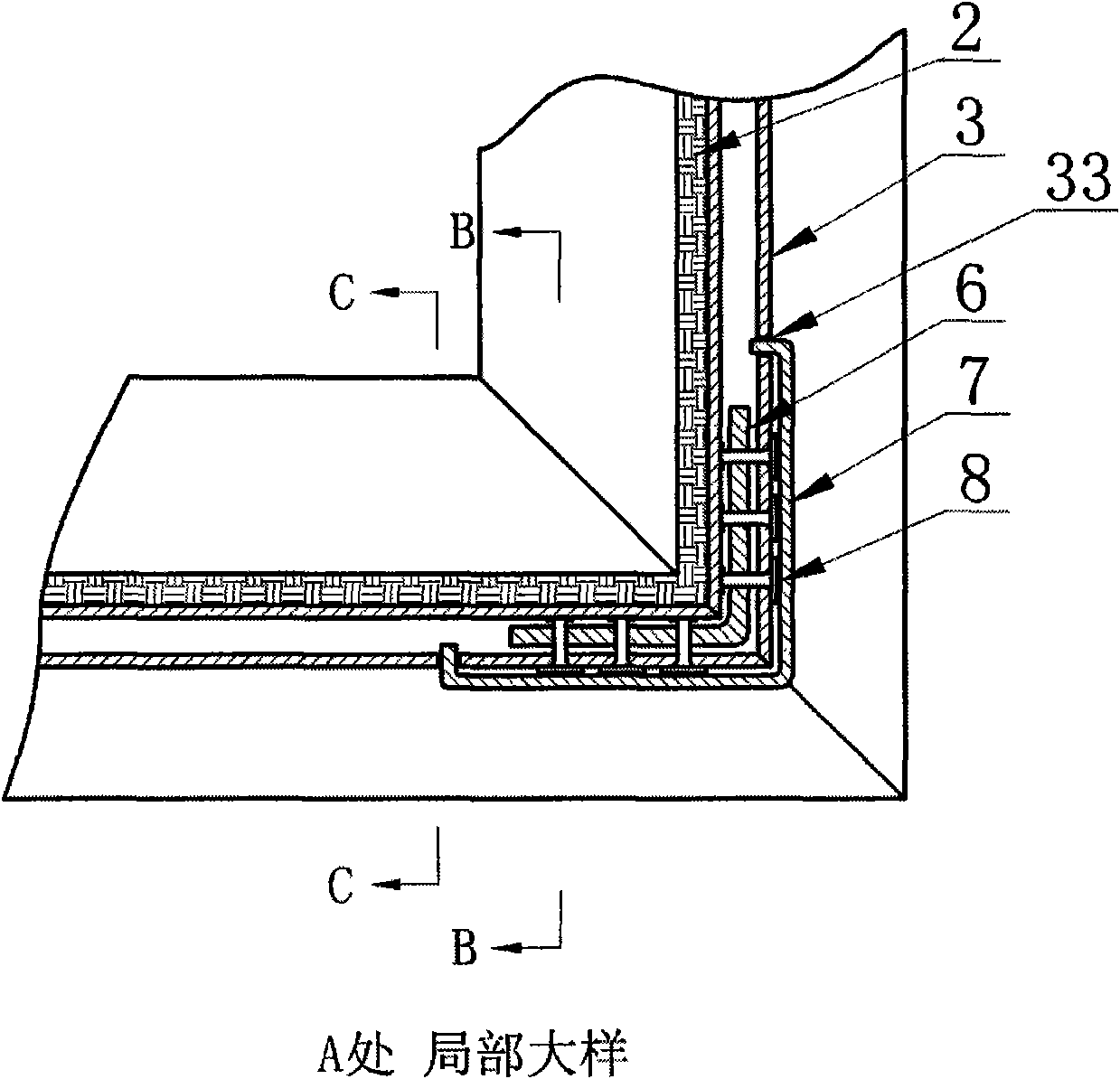

[0023] The fixed connection structure of the transparent unit board of the sound barrier of the present invention will be described with reference to the drawings and embodiments.

[0024] The entire system of the plug-in metal sound barrier is composed of several H-shaped steel columns with a certain span, and several aluminum alloy unit plates are inserted between every two H-shaped steel columns, and the unit plate of transparent material is placed on the top.

[0025] Such as Figure 1 to Figure 9 As shown, the fixed connection structure of the sound barrier transparent unit panel of the present invention includes a plurality of fixed connection parts at the corners of the quadrilateral. The center is a transparent material acrylic board 1, which has the characteristics of high strength, strong light transmittance and good sound insulation effect. The aluminum alloy profile frame 3 plays the roles of support, connection and positioning around the overall transparent mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com