Method for preparing polyimide/silver composite conductive fiber

A polyimide fiber, composite conductive technology, applied in fiber type, fiber treatment, textiles and paper making, etc., can solve the problems of low production efficiency, poor quality, high cost, etc., and achieve easy operation, short time consumption, and high adhesion The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

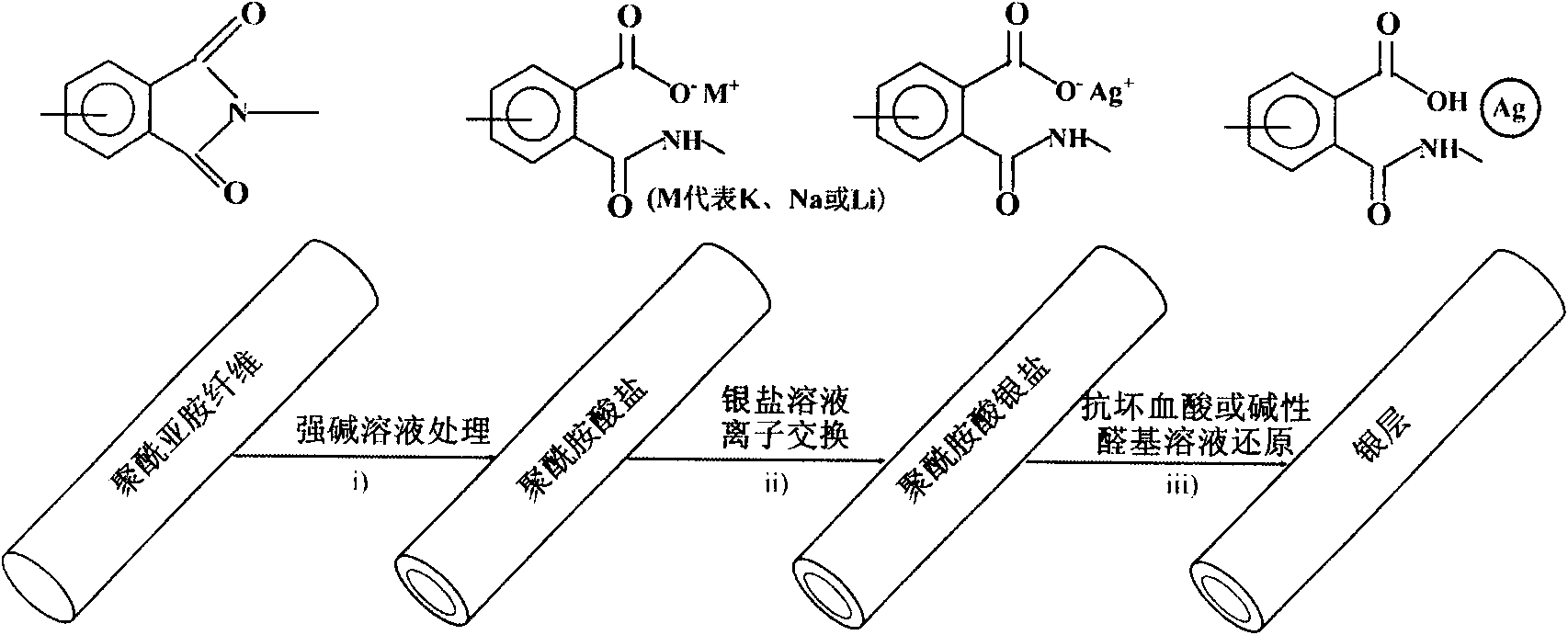

Method used

Image

Examples

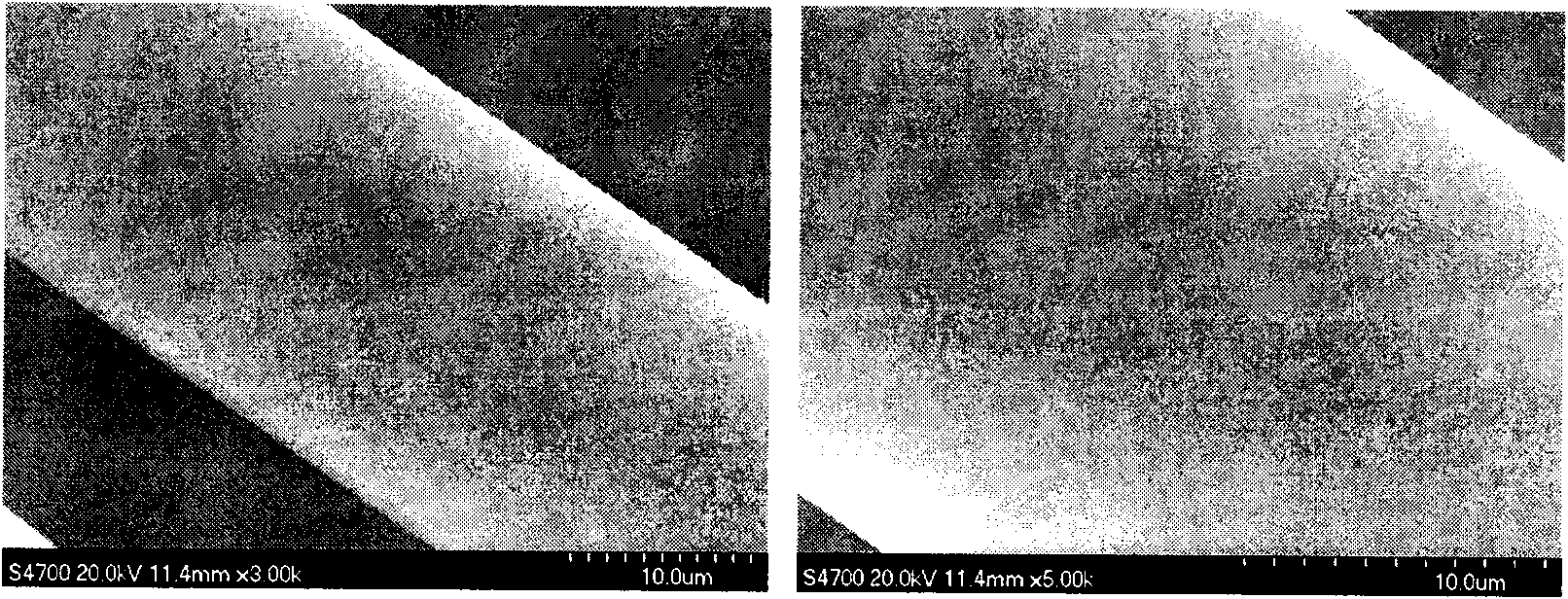

Embodiment 1

[0028] A: The finished polyimide fiber is ultrasonically treated in deionized water for 30 minutes to remove surface impurities and dried, then immersed in 2mol / l potassium hydroxide aqueous solution at room temperature for 1 hour, and then soaked in deionized water 5 minutes to remove the potassium hydroxide attached to the surface, and dry in the air;

[0029] B: Immerse the polyimide fiber treated with strong alkali solution in step A in 0.4mol / l silver nitrate aqueous solution, after ion exchange at room temperature for 1 hour, wash it with deionized water, and let it dry in the air for 12 Hour;

[0030] C: The polyimide fiber that the surface layer obtained in step B is covered with polyamic acid silver salt is immersed in the ascorbic acid aqueous solution of 0.02mol / l, takes out after reacting at room temperature for 20 minutes, washes with deionized water, dries, obtains Polyimide / silver composite conductive fibers.

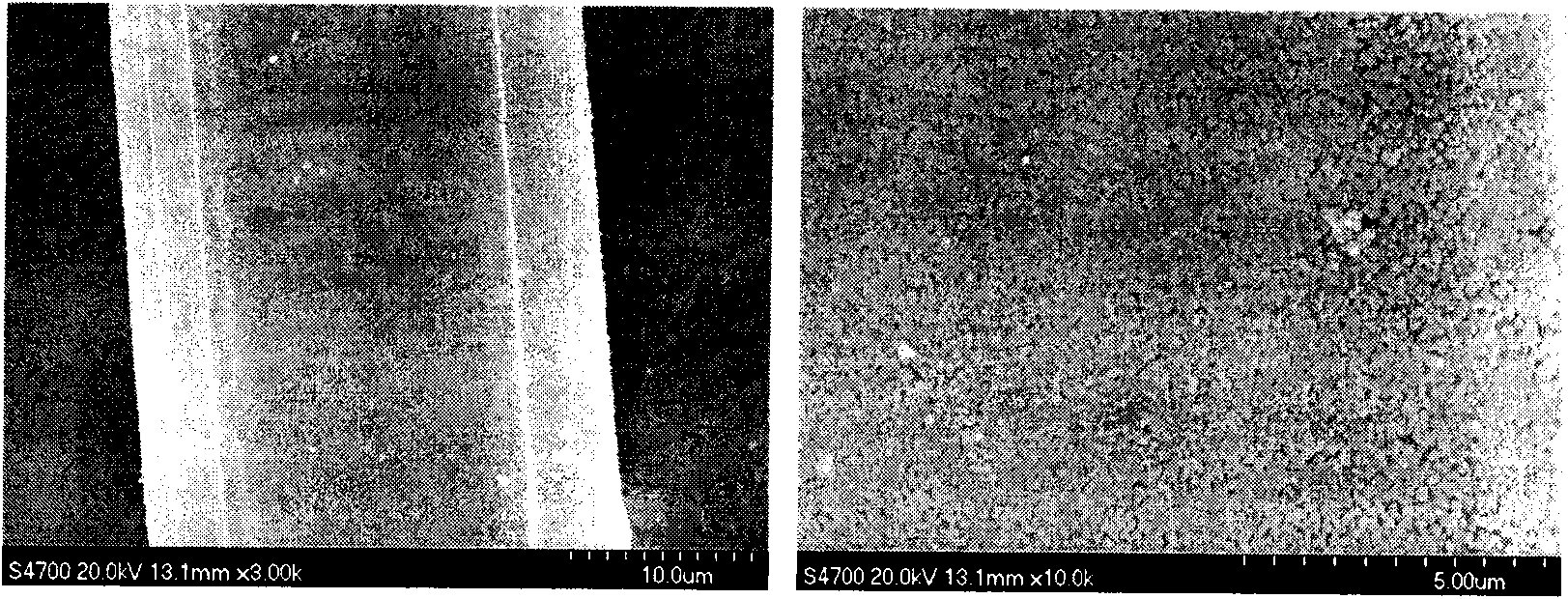

Embodiment 2

[0032] A: The finished polyimide fiber is ultrasonically treated in deionized water for 30 minutes to remove surface impurities and dried, then immersed in 2mol / l sodium hydroxide aqueous solution at room temperature for 1.5 hours, and then soaked in deionized water 5 minutes to remove the sodium hydroxide attached to the surface, dry in the air;

[0033] B: Immerse the polyimide fibers treated with strong alkali solution in step A in 0.4mol / l silver nitrate aqueous solution, after ion exchange at room temperature for 3 hours, wash with deionized water, and let it dry in the air for 12 Hour;

[0034] C: the polyimide fiber that the surface layer obtained in step B is covered with polyamic acid silver salt is immersed in the ascorbic acid aqueous solution of 0.25mol / l, takes out after reacting at room temperature for 10 minutes, washes with deionized water, dries, obtains Polyimide / silver composite conductive fibers.

Embodiment 3

[0036] A: with step A in embodiment 1;

[0037] B: Immerse the polyimide fiber treated with strong alkali solution in step A in 0.04mol / l silver ammonia solution, after ion exchange at room temperature for 5 minutes, wash it with deionized water, and let it dry in the air for 12 Hour;

[0038] C: with step C in embodiment 2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com