Preparation method of casting water glass

A technology for water glass and industrial use, which is applied in the field of preparation of water glass for casting. It can solve the problems that the wet process has not been popularized and applied in large quantities, has a lot of solid residues, and endangers the ecological environment, so as to improve the working environment of workers and benefit the environment. Effect of protecting and reducing environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

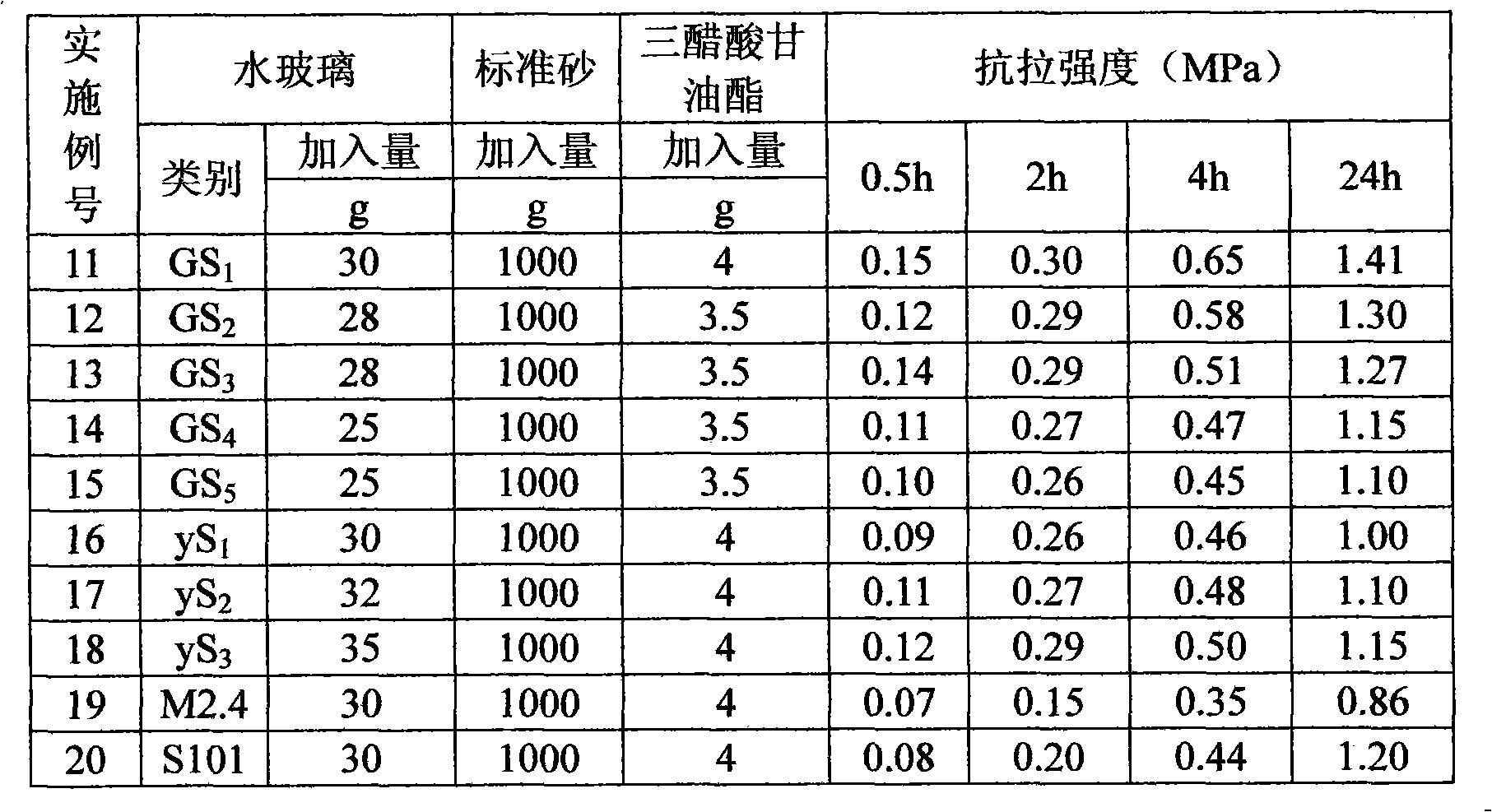

Embodiment 1

[0053] Ratio of feeding: quartz powder 209kg, industrial solid sodium hydroxide 129kg, water 165kg, steam 150kg.

[0054] Put the material into the mixing tank and stir evenly, pump it into the autoclave with a mortar pump, close the feeding port, feed steam, and keep warm at 0.6MPa for 2 hours. Continue to feed steam, keep warm at 0.9MPa for 10h, release the pressure to 0.3MPa, open the discharge port, press the product into the intermediate tank with the residual pressure in the autoclave to cool, when the material drops below 70°C, put the material Go to the separation tank, use a plate suction filter to suck the liquid material into the storage tank, receive 608kg of liquid material, and let it stand for 72h, including 574kg of transparent liquid water glass, which is recorded as S 1 , cloudy water glass 34kg, denoted as yS 1 , Separated unreacted matter 45kg. The modulus of water glass is 2.3 and the density is 1.50g / cm 3 .

Embodiment 2

[0056] Feeding ratio: 204kg of quartz powder, 126kg of industrial solid sodium hydroxide, 9kg of solid potassium hydroxide, 150kg of water, and 163kg of steam.

[0057] Put the material into the mixing tank, stir evenly, put it into the pressure kettle with a mortar pump, close the feeding port, feed steam, keep it at 0.6MPa for 4 hours, continue to feed steam at 1.2MPa and keep it for 9 hours, and release the pressure to 0.3MPa. Open the discharge port, use the residual pressure in the autoclave to pump the product into the intermediate tank to cool, when the material drops below 70°C, put the material into the separation tank, and use the suction filter to suck the liquid material into the storage tank. Received 629kg of liquid material, let it stand for 48h, and obtained 581kg of transparent liquid water glass, denoted as S 2 , cloudy water glass 48kg, denoted as yS 2 , Separated 23kg of unreacted matter. The modulus of water glass is 2.5 and the density is 1.49g / cm 3 . ...

Embodiment 3

[0059] Ratio of feeding: 130kg of quartz powder, 110kg of industrial solid sodium hydroxide, 80kg of industrial solid potassium hydroxide, 51kg of water, 155kg of steam, 68kg of suction filtration residue in example 1 and example 2.

[0060] Referring to the method of Example 1, put the mixed material into the autoclave, close the feeding port, feed steam to heat, keep the temperature at 0.8MPa for 1h, then feed steam and increase the pressure, keep the temperature at 1.8MPa for 4.5h, and release the pressure to 0.3 Under MPa, and refer to example 1 method operation, obtain liquid water glass 580kg, leave standstill 72h, obtain transparent liquid water glass 540kg, record as S 3 , cloudy water glass 40kg, denoted as yS 3 , Solid-liquid separation remaining material 14kg. The modulus of water glass is 2.5 and the density is 1.49g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com