Inner-filtering bag-type deduster

A dust collector and internal filter technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of time-consuming and labor-intensive efficiency, large investment in processing equipment, processing difficulties, etc., to overcome the requirements of high precision, Improve the effective utilization rate, the effect of simple and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

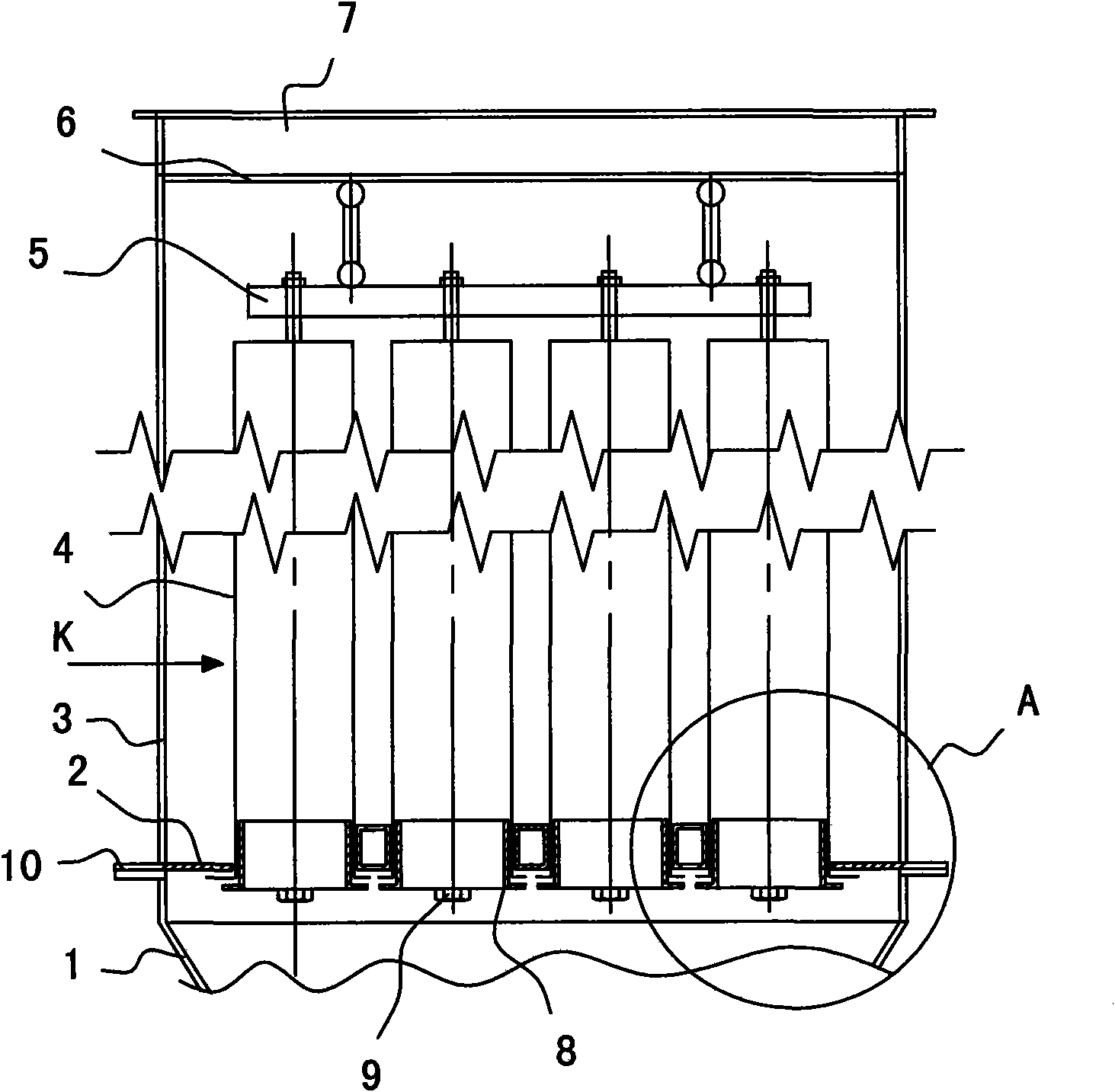

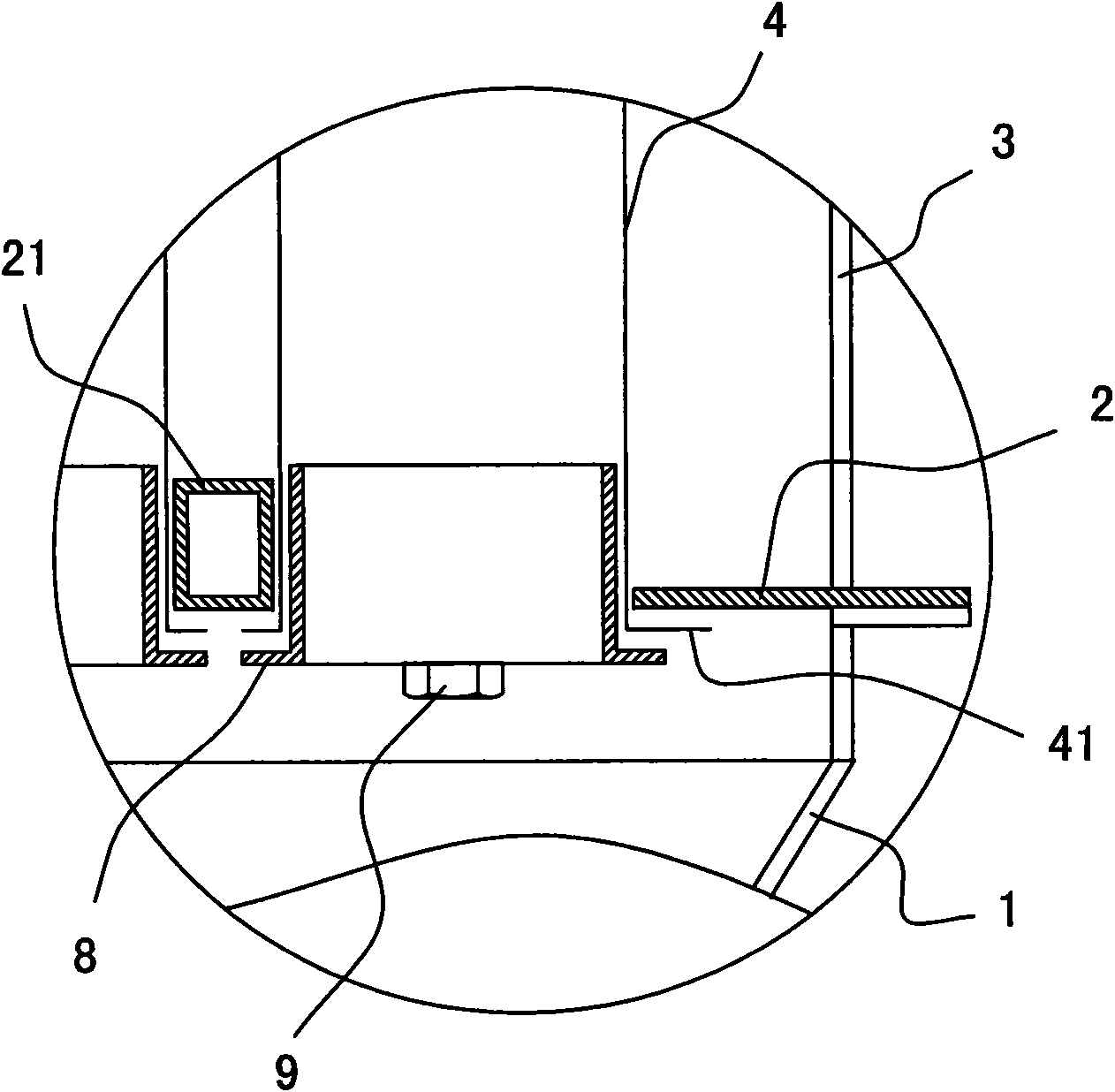

[0021] see figure 1 , and combined with figure 2 . From bottom to top, the dust removal box is formed by connecting the lower box 1, the middle box 3 and the upper box 7 through flanges, and the flange 10 connects the lower box 1 and the upper box 7, and the lower box 1 is in the shape shape, the air inlet is located on the side wall of the lower box body 1, and the middle box body 3 and the upper box body 7 are mainly used for setting the one-piece cloth bag 4 and its fixing components. During operation, the dust-laden wind enters from the air inlet, and then is filtered through the bag wall of the one-piece cloth bag 3 filter cartridge 45, and the clean wind passes through the bag wall, and then is discharged under the action of the upper air inlet. The dust particles remain in the 4 bags of one-piece cloth bags. When the dust particles accumulate to a certain amount, the dust particles fall into the conical lower box 1 after dust cleaning.

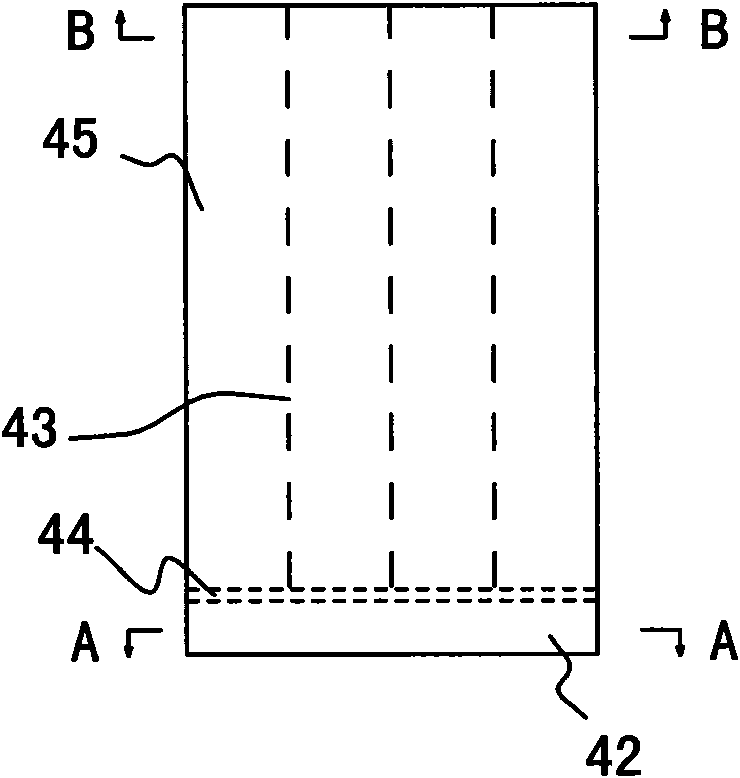

[0022] see Figure 3-Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com