Magnetic flow convertor with permanent magnet

A magnetic flux converter and permanent magnet technology, applied to the power device inside the switch, the protection switch operation/release mechanism, etc., can solve the problems of complex structure, large volume, and complicated production process of the shell and cover, and achieve high use Value, good economic benefits, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

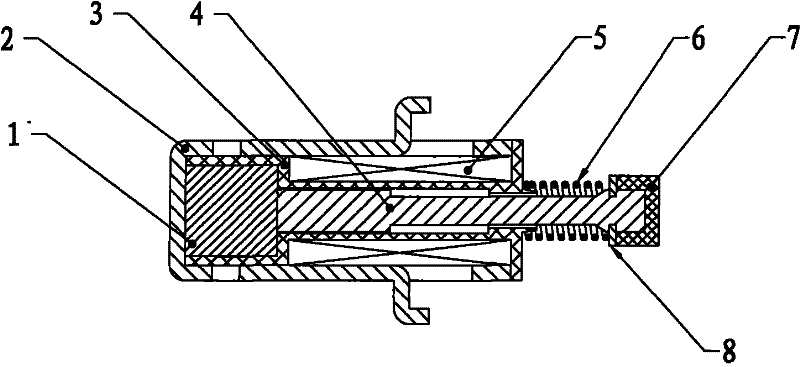

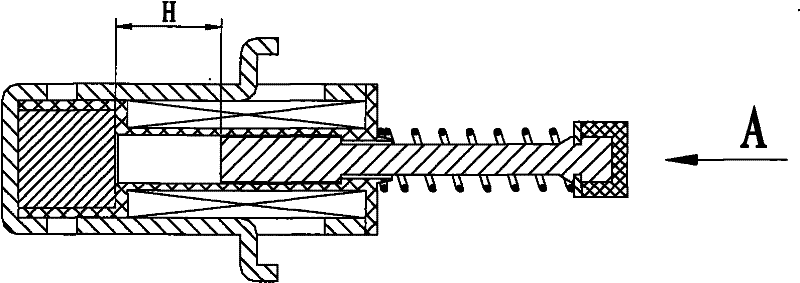

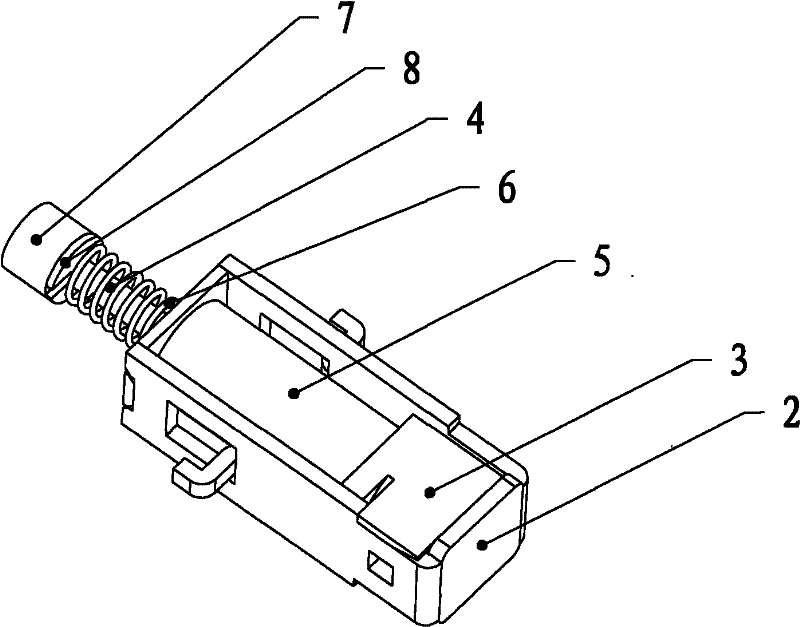

[0019] refer to figure 1 , which is a structural schematic diagram of a magnetic flux converter in the pull-in position of the present invention.

[0020] As shown in the figure, it is an embodiment, including a U-shaped magnetic yoke (2) with symmetrical fixed claws on both sides. The magnetic yoke is equipped with a bobbin (3), ejector rod (4), coil (5), and a permanent magnet. (1) is fixed between the U-shaped yoke (2) and a part of the bobbin (3). Also housed in the coil bobbin (3), and a step hole is designed to prevent the push rod (4) from protruding. Push rod (4) is equipped with, jump ring (8) and buffer pad (7).

[0021] figure 1 What is shown is that the magnetic flux converter is in the state of attraction, and the ejector rod receives two forces in opposite directions, which are the attraction force of the permanent magnet to the ejector rod and the repulsion force of the spring to the ejector rod. In the state of attraction, the force of the permanent magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com