High abrasion resistance tape, particularly for bandaging cable harnesses in cars

A cable harness, high technology, applied in the field of highly wear-resistant belts to achieve the effect of increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

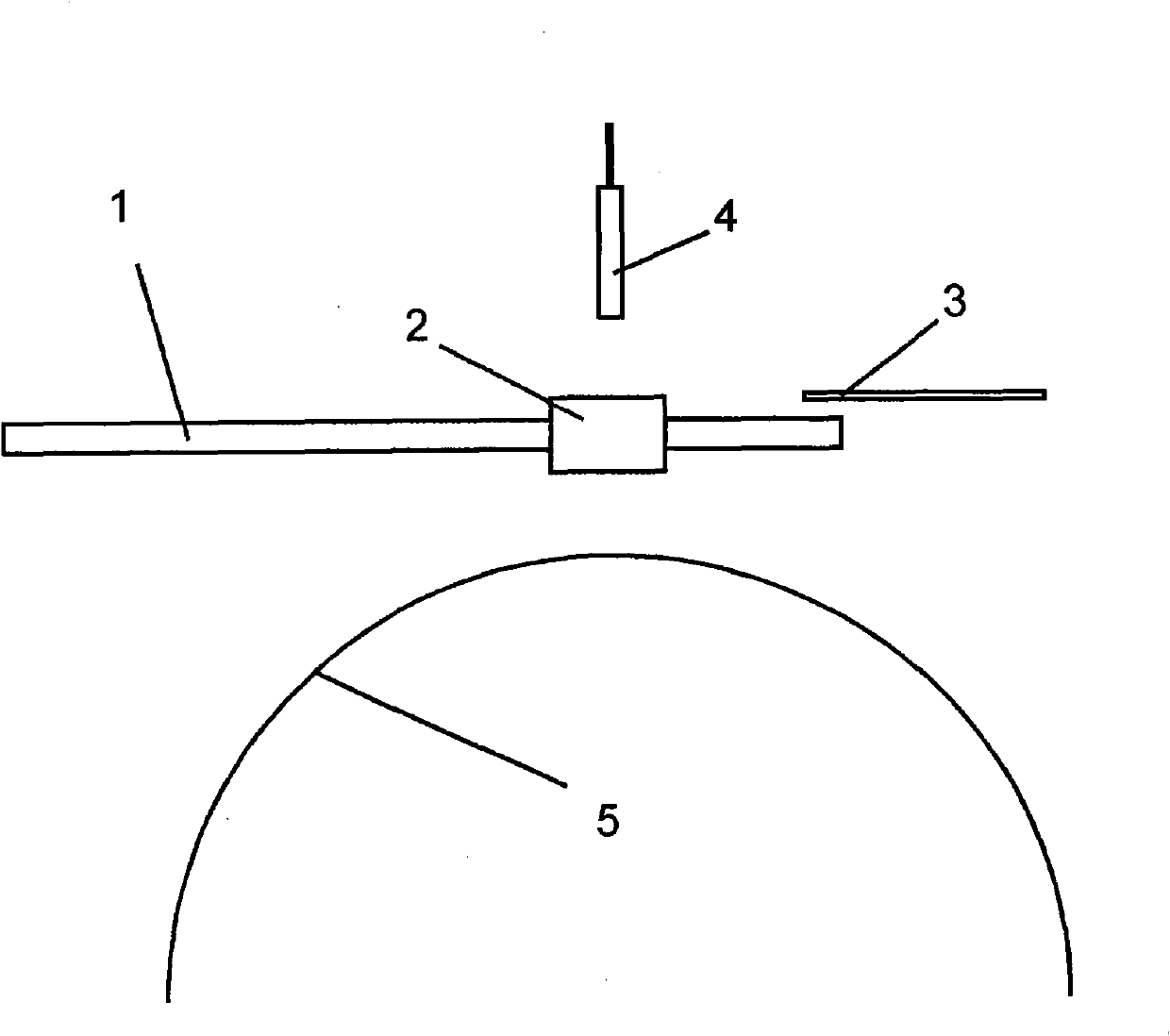

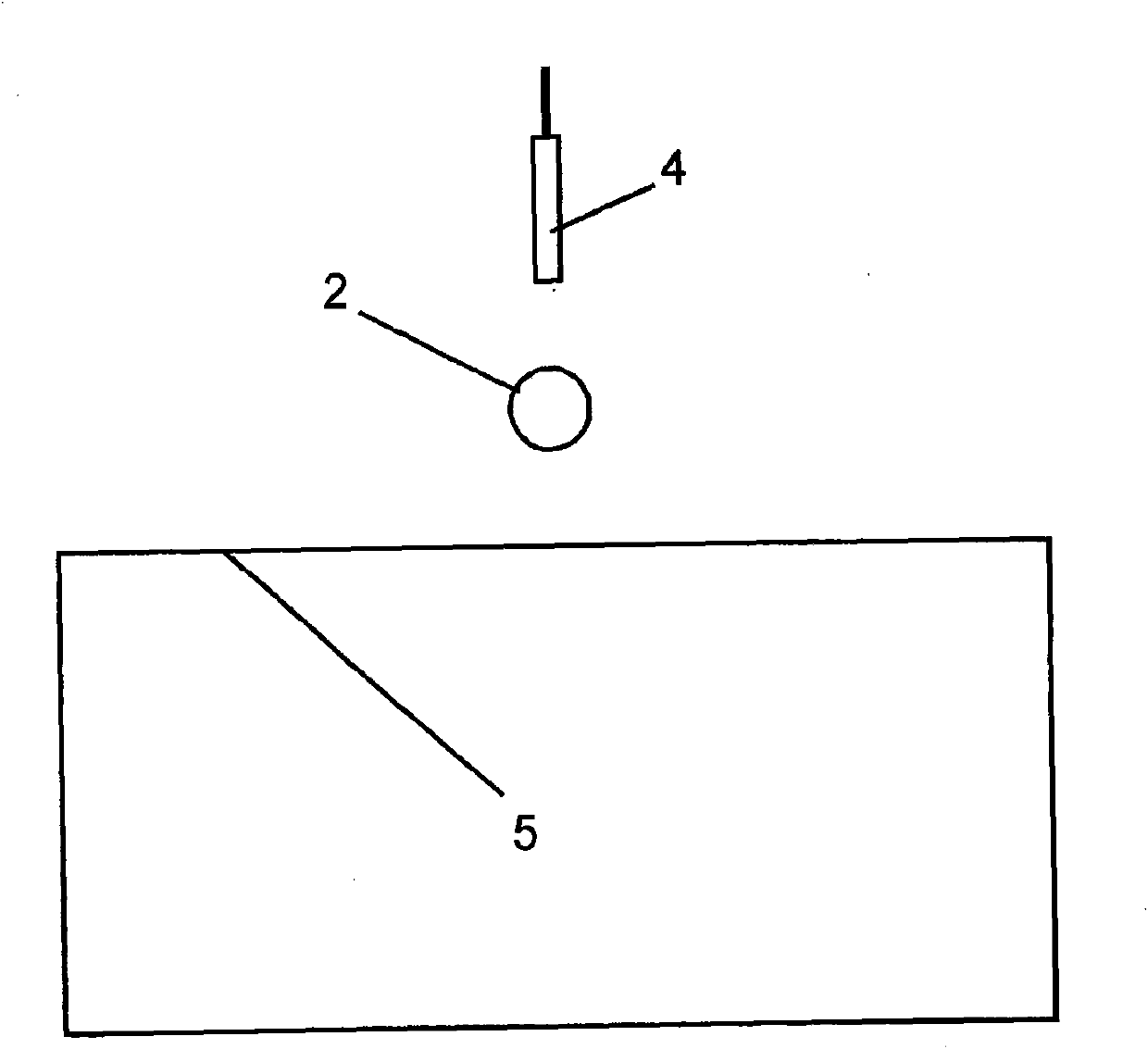

Method used

Image

Examples

Embodiment 1

[0185] Embodiment 1 (of the present invention)

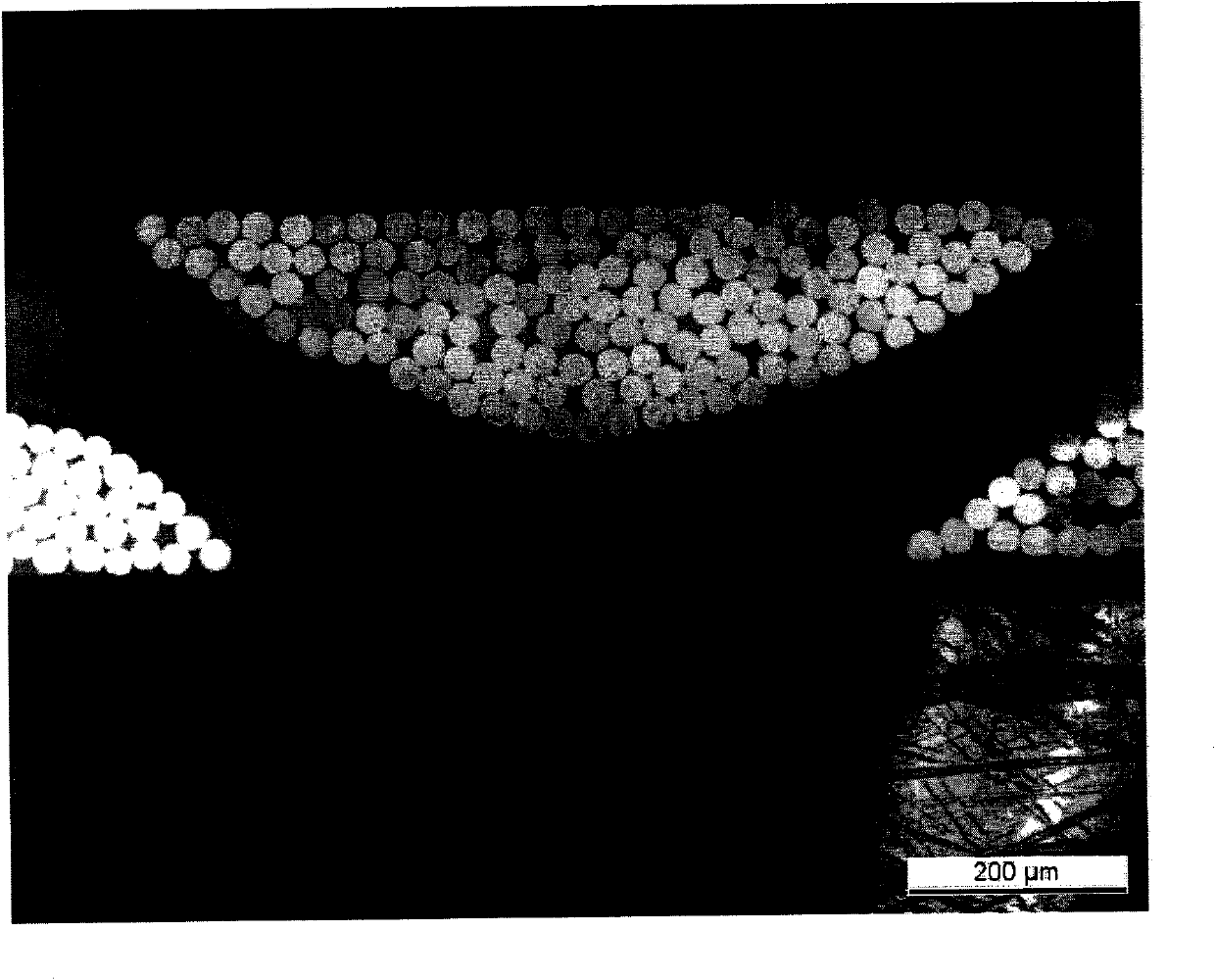

[0186] Nylon 6,6 yarns (linear density 1100 decitex, and 140 filaments / yarn) from INVISTA were woven in a plain weave structure with a set of 13 warp yarns / cm and 12 weft yarns / cm, Produces a unit weight of 280g / m 2 . The obtained fabric exhibited an ultimate tensile strength of 680 N / cm, an elongation at break of 36% and a flexural stiffness of 0.044N. at 120g / m 2 Coating with an acrylate adhesive yielded tapes exhibiting LV312 wear class F on 5-mm and 10-mm mandrels.

[0187] ISO 6722 wear, 7N / 5-mm mandrel

Embodiment 2

[0188] Embodiment 2 (of the present invention)

[0189] Nylon 6,6 yarns (with a linear density of 470 dtex and 144 filaments / yarn) in a plain weave structure of 20 ends / cm and 20 wefts / cm yield a basis weight of 210 g / m 2 . The prepared fabric exhibited a flexural stiffness of 0.046N, an ultimate tensile strength of 650N / cm and an elongation at break of 47%. at 100g / m 2 Coating with an acrylate adhesive yielded tapes exhibiting LV312 wear class F on 5-mm and 10-mm mandrels.

[0190] ISO 6722 wear, 7N / 5-mm mandrel

Embodiment 3

[0191] Embodiment 3 (of the present invention)

[0192] Nylon 6 yarns (with a linear density of 470 dtex and 136 filaments / yarn) were woven in a plain weave structure with a set of 21 warp / cm and 15 weft / cm yielding a basis weight of 190 g / cm. m 2 . The fabric exhibited a flexural stiffness of 0.029N. at 100g / m 2 Coating with an acrylate adhesive yielded tapes exhibiting LV312 wear class E on 5-mm and 10-mm mandrels.

[0193] ISO 6722 wear, 7N / 5-mm mandrel

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com