Manual/automatic gearbox for mutually floating gear

An automatic transmission and gear technology, applied in the field of transmission systems, can solve the problems of high manufacturing precision, high production cost, low transmission efficiency, etc., and achieve the effects of low manufacturing cost, low maintenance cost and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the present invention, there are two pistons floating in the clutch of each gear position of the mutually floating gear, and the speed change is realized by the main and secondary gears in the speed change mechanism, and the gear shift is controlled by hand or automatically selected by the hydraulic electronic control system. , manual shift and automatic shift are two independent shift systems.

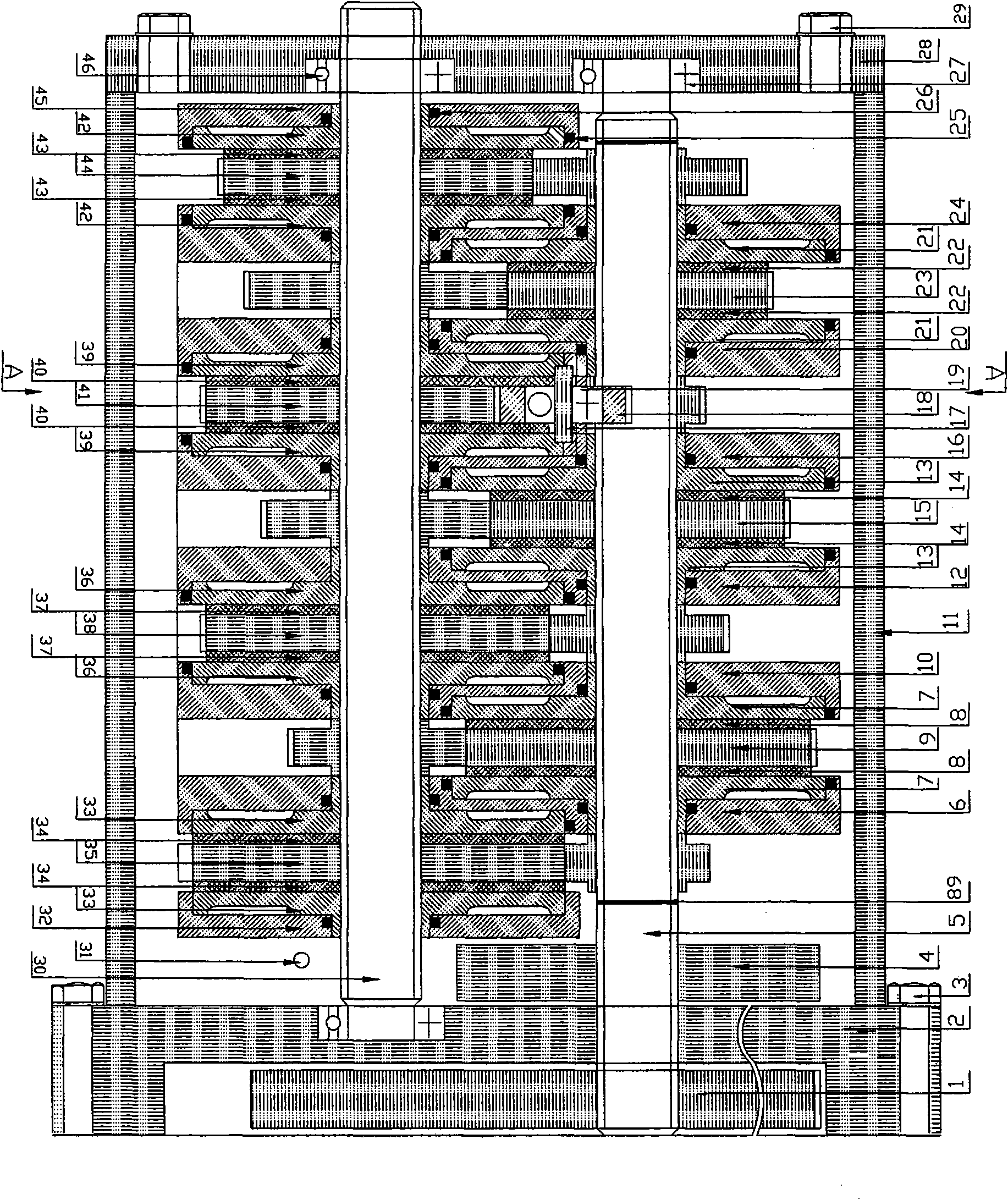

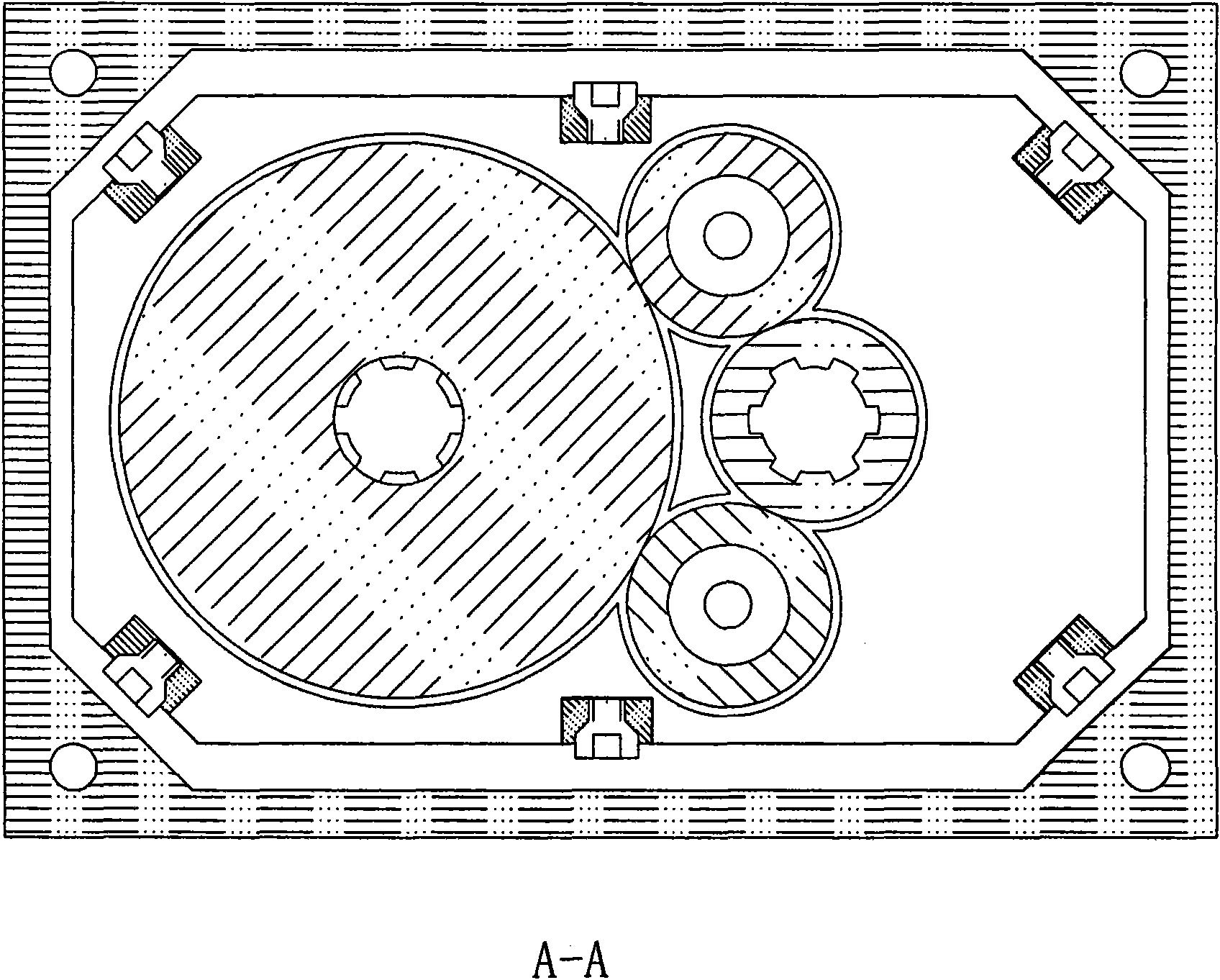

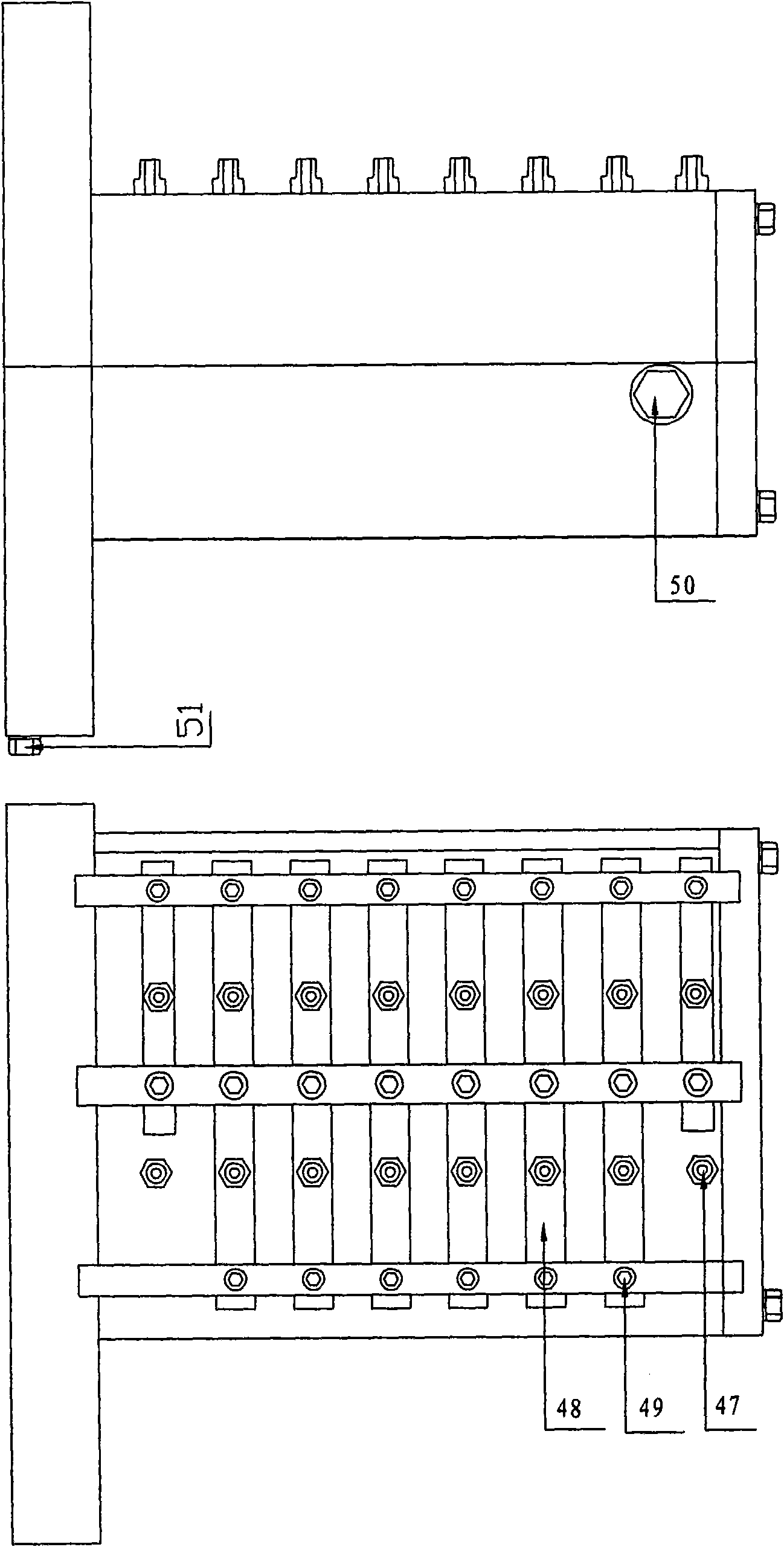

[0040] see figure 1 , figure 2 and image 3 , Interfloating gear manual and automatic transmissions are mainly composed of basic parts, gear transmission mechanisms, clutch mechanisms and hydraulic electronic control systems (stepping motor speedometer hydraulic control systems). The basic parts are mainly composed of flywheel 1, flywheel housing and rubber pad 2, gearbox body and gearbox body rubber pad 11, gearbox rear cover and gearbox rear cover rubber pad 28, 6-M12x65 bolts, diameter 12 flat pads and spring pads 3. It consists of 4-M10X317 bolts, flat washers with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com